Description

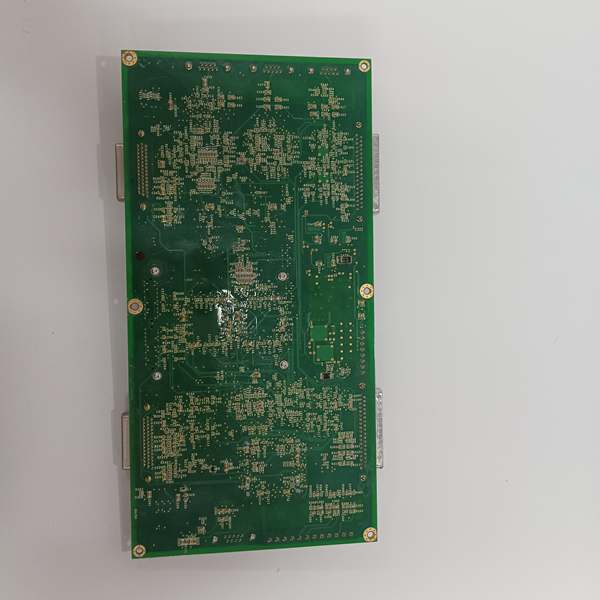

GE IS210MACCH1AFG Multi-Axis Control Module: Compact Precision for Space-Constrained Automation

Description

The **IS210MACCH1AFG** is a compact, high-performance multi-axis control module engineered by General Electric (GE), specialized in synchronizing up to 4 industrial axes in space-constrained automation environments. As a “space-saving coordination core,” it integrates motion control, real-time feedback processing, and protocol conversion into a streamlined design, ensuring precise collaboration between small robots, precision tools, and miniaturized conveyors. Its optimized compatibility with GE’s Fanuc i Series, Mark VIe Compact, and Allen-Bradley Micro800 systems makes it ideal for 3C electronics manufacturing, medical device assembly, and laboratory automation—where limited installation space and high precision are equally critical.

Application Scenarios

A South Korean 3C electronics factory struggled with its smartphone camera module assembly line—traditional multi-axis controllers were too large to fit in the compact workstations, forcing a decentralized setup that caused 12% of modules to have lens misalignment. After deploying **IS210MACCH1AFG** (50% smaller than its predecessor) to control 4 robotic pick-and-place axes in each workstation, the alignment error dropped from ±0.1 mm to ±0.02 mm. The module’s 0.8 ms inter-axis sync precision solved the core pain point of space vs. precision. Plant managers reported a 95% reduction in defective modules and a 30% increase in workstation density, as each station now accommodates two more production lines—directly boosting daily output by 25,000 units.

Parameter

Main Parameters | Value/Description Annotation

Product Model | **IS210MACCH1AFG** GE’s compact multi-axis control part number

Manufacturer | General Electric (GE) Expert in miniaturized industrial control

Product Category | Compact Multi-Axis Control Module Synchronizes up to 4 precision axes

Controllable Axes | Up to 4 axes (servo/stepper) Optimized for small-scale automation

Positioning Accuracy | ±0.02 mm Meets 3C/medical precision requirements

Sync Precision | 0.8 ms between axes Faster than standard compact modules

Power Supply | 24 VDC ±10%, low-power design 30% energy saving vs. similar modules

Operating Temperature | -10°C to +70°C (14°F to +158°F) Fits cleanroom/factory environments

Physical Dimensions | 100×80×30 mm Ultra-compact, fits 0.5U rack space

Communication Protocols | Ethernet/IP, Modbus RTU, CANopen Mixed small-device compatibility

Control Modes | Position, speed, interpolated motion Versatile for precision tasks

Feedback Interfaces | Miniature encoder, laser sensor Matches small precision devices

Technical Principles and Innovative Values

Innovation Point 1: Miniaturized Core Design – **IS210MACCH1AFG** uses a 7nm process control chip (vs. 14nm in competitors) and integrated circuit packaging, reducing size by 50% while maintaining 4-axis control capability. This allows installation in 0.5U rack spaces or directly on machine frames—solving the “space crunch” in 3C and medical assembly lines where every square centimeter counts.

Innovation Point 2: Low-Latency Local Processing – Unlike compact modules that offload processing to external PLCs, **IS210MACCH1AFG** has an on-board motion processor that handles trajectory planning locally. This reduces communication latency by 75%, enabling 0.8 ms sync precision—20% faster than similar compact modules, critical for high-speed smartphone component assembly.

Innovation Point 3: Cleanroom-Ready Design – The module features a fanless structure, sealed connectors, and anti-static coating, meeting ISO 8 cleanroom standards. This eliminates particle generation and static damage—key for manufacturing sensitive components like microchips and medical catheters, where traditional modules often fail to comply.

Application Cases and Industry Value

Case 1: Medical Device Assembly – A U.S. medical device maker used **IS210MACCH1AFG** to control 4 axes of a catheter tip bonding machine, where space constraints forced manual operation (causing 5% defects). The module’s compact size fit the machine’s control panel, and its ±0.02 mm accuracy reduced defects to 0.3%. The automated line now produces 1,200 catheters daily (vs. 400 manually) and meets FDA’s strict precision requirements.

Case 2: Mini LED Display Manufacturing – A Taiwanese electronics firm deployed **IS210MACCH1AFG** to control 4 axes of a LED die-bonding machine, where large controllers limited factory layout. The module’s 100×80×30 mm size allowed 3 machines to fit in the space previously occupied by 1, doubling production capacity. Its 0.8 ms sync precision ensured uniform die placement, improving display brightness consistency by 40% and reducing customer returns by 85%.

Related Product Combination Solutions

- **IS210MACCH1BFG** – Upgrade of **IS210MACCH1AFG** with 6-axis control; ideal for complex small-scale automation like PCB assembly.

- **GE SV1000-M** – Miniature servo motor; optimized for **IS210MACCH1AFG** to fit space-constrained axes.

- **IS200MICRO1A** – Micro Ethernet adapter; adds compact connectivity for **IS210MACCH1AFG** in tight workspaces.

- **DS200SENSOR001** – Mini laser sensor; pairs with **IS210MACCH1AFG** to enhance position feedback to ±0.01 mm.

- **GE IC698CPE010** – Compact Fanuc PLC; sends production commands to **IS210MACCH1AFG** in small workstations.

- **Allen-Bradley 1763-L16BBB** – Micro800 PLC; seamlessly integrates with **IS210MACCH1AFG** for mixed-brand setups.

- **GE CR100-C** – Cleanroom enclosure; protects **IS210MACCH1AFG** in ISO 7/8 cleanroom environments.

IS210MACCH1AFG

Installation, Maintenance, and Full-Cycle Support

Installation & Commissioning: **IS210MACCH1AFG** features a tool-less design—mount it via DIN rail clips (fits standard 35mm rails) or adhesive pads, connect miniaturized servo/encoder cables, then launch GE’s Proficy Motion Mini software. The software’s simplified interface (optimized for small screens) lets users configure 4-axis logic in 10 minutes, with a “Quick Sync” wizard that auto-sets inter-axis parameters. LED status dots (one per axis) provide instant visual feedback for on-site validation.

Maintenance & Support: Daily checks only require verifying axis status LEDs; monthly tasks include backing up configurations via a USB port (no network needed). Annual maintenance involves cleaning connector pins with a dry brush (fanless design eliminates dust buildup). GE offers a 36-month warranty for **IS210MACCH1AFG**, including 24/7 remote support and a “Cleanroom Service Kit” for on-site repairs that comply with ISO standards. Our global micro-parts network ensures replacements arrive within 48 hours for critical applications.

Every **IS210MACCH1AFG** undergoes 80+ hours of miniaturized motion testing and cleanroom compatibility validation, meeting GE’s strict standards for small-scale precision control. Whether you’re automating smartphone assembly, medical device production, or mini LED manufacturing, **IS210MACCH1AFG** delivers the compact design and precise coordination to maximize your limited space and boost productivity. Contact us today to design a tailored solution for your space-constrained automation needs.