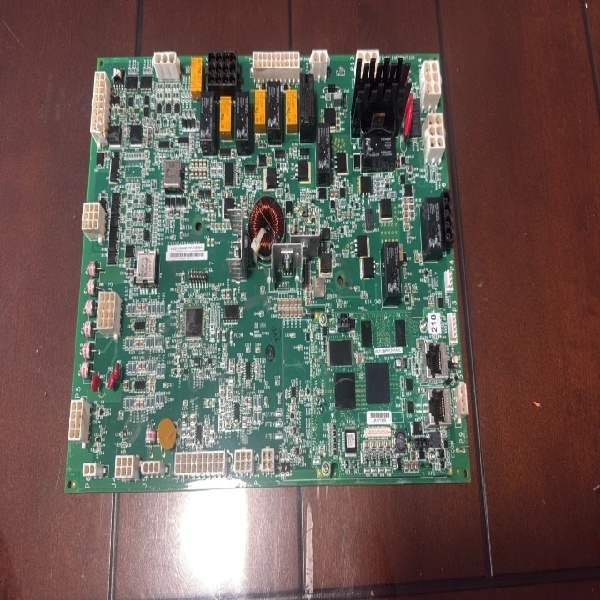

Description

GE IS210MACCH1AFG Mark VIe Control Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210MACCH1AFG** Manufacturer | GE General Electric Product Category | Industrial Control Module Series | Mark VIe (Turbine Control System) Processor | 32-bit PowerPC, 600 MHz Memory | 512 MB RAM, 256 MB Flash Communication Protocols | GE SRTP, Modbus TCP, Ethernet/IP, Profinet I/O Interfaces | 8×Digital Inputs, 8×Digital Outputs, 4×Analog Inputs (4-20mA) Operating Voltage | 24V DC (±10%) Operating Temperature | 0°C to 60°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 140mm × 100mm × 30mm Certifications | IEC 61508 (SIL 3), UL 508, CE

Product Introduction

The **GE IS210MACCH1AFG** is a high-performance control module that serves as the core processing unit of GE’s Mark VIe turbine control system, specifically engineered for gas, steam, and hydro turbine applications. As a flagship component in GE’s industrial control portfolio, the **GE IS210MACCH1AFG** integrates advanced processing capabilities with dedicated turbine control algorithms, enabling precise regulation of speed, load, and safety functions. Its design is tailored to meet the rigorous demands of power generation, where reliability and real-time responsiveness are critical to operational efficiency.

What distinguishes the **GE IS210MACCH1AFG** is its seamless integration within the Mark VIe ecosystem, working in tandem with I/O modules, HMI interfaces, and safety systems to form a comprehensive control solution. Leveraging GE’s decades of turbine control expertise, the **GE IS210MACCH1AFG** ensures stable operation under dynamic load conditions, reduces start-up time, and minimizes emissions—delivering tangible value by enhancing turbine performance and extending service life for power plant operators worldwide.

Core Advantages and Technical Highlights

Turbine-Specific Control Logic: The **IS210MACCH1AFG** comes preloaded with GE’s proprietary turbine control algorithms, optimized for speed governing, load sharing, and fault protection. These built-in functions eliminate the need for custom programming, reducing deployment time while ensuring compliance with industry-specific performance standards—critical for gas turbine applications requiring rapid response to grid frequency changes.

High Reliability (SIL 3 Certified): Compliant with IEC 61508 SIL 3 standards, the **IS210MACCH1AFG** features redundant processing paths and built-in self-diagnostic functions. It continuously monitors internal components and communication links, triggering automatic failover to backup modules if anomalies are detected—ensuring uninterrupted operation in mission-critical power generation scenarios where downtime can result in significant revenue loss.

Multi-Protocol Connectivity: Equipped with support for GE SRTP, Modbus TCP, and Ethernet/IP, the **IS210MACCH1AFG** seamlessly connects to plant DCS systems, SCADA platforms, and remote monitoring tools. This versatility allows power plant operators to integrate turbine data into centralized control networks, facilitating predictive maintenance and data-driven optimization of the entire generation process.

Efficient Thermal Management: The **IS210MACCH1AFG** incorporates a passive heat dissipation design with high-conductivity aluminum housing, eliminating the need for fans. This reduces moving parts and failure points, while ensuring stable performance even in the high-temperature environments of turbine enclosures—enhancing long-term reliability and lowering maintenance costs.

IS210MACCH1AFG

Typical Application Scenarios

In combined cycle power plants, the **IS210MACCH1AFG** serves as the primary control unit for gas turbines, regulating fuel flow and air intake to maintain optimal efficiency across varying load demands. It communicates with heat recovery steam generators (HRSGs) via Ethernet/IP, coordinating turbine output with steam production to maximize overall plant efficiency—delivering significant fuel savings for operators.

For industrial cogeneration facilities (used in manufacturing, refineries, and campuses), the **IS210MACCH1AFG** controls both turbine speed and heat extraction, balancing electrical power generation with thermal energy needs for processes like heating or steam production. Its precise load-sharing capabilities ensure stable power supply to on-site grids while meeting the facility’s thermal requirements, reducing reliance on external energy sources.

In hydroelectric power plants, the **IS210MACCH1AFG** manages turbine governor systems, adjusting runner blades and wicket gates to respond to changes in water flow and grid demand. Its SIL 3 certification ensures compliance with safety standards for dam and turbine operations, while its compatibility with GE’s PlantPAx DCS allows integration into regional power grid management systems—supporting grid stability and renewable energy integration.

Related Model Recommendations

**IS210MACCH1BFG**: Enhanced variant of **IS210MACCH1AFG** with 16 digital I/O channels, designed for large-scale turbine systems with extended monitoring requirements.

**IS210MCCPG1A**: Mark VIe communication module that extends **IS210MACCH1AFG**’s connectivity to legacy turbine control systems via RS-485 Modbus.

**IS210IAIH1A**: Analog input module paired with **IS210MACCH1AFG** to collect pressure, temperature, and vibration data from turbine sensors.

**IC754VSF15CTD-JH**: GE VersaMax HMI that displays real-time turbine data from **IS210MACCH1AFG**, enabling operators to monitor speed, load, and fault alerts.

**IS210MCPMG1A**: Power management module for Mark VIe systems, ensuring stable 24V DC supply to **IS210MACCH1AFG** and associated I/O modules.

**IS210MAGSG1A**: Safety logic module that works with **IS210MACCH1AFG** to implement emergency shutdown functions, complying with SIL 3 requirements.

**IS210MACCH1AFG-R**: Refurbished version of **IS210MACCH1AFG**, offering cost-effective replacement for legacy Mark VIe systems without compromising performance.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210MACCH1AFG**, ensure the Mark VIe chassis is powered off and grounded to prevent ESD damage. Verify the chassis slot is compatible with Mark VIe modules and the 24V DC power supply is within the ±10% tolerance range. Label all I/O wires according to the turbine control schematic to avoid misconnection, and use shielded cables for analog inputs to reduce electromagnetic interference from turbine generators.

Maintenance suggestions: Conduct monthly visual inspections of **IS210MACCH1AFG**, checking for loose wiring and dust accumulation—use compressed air (max 0.3 MPa) to clean the module’s ventilation slots. Run quarterly diagnostic tests via GE’s Turbine Control Studio software to verify processor performance and communication integrity. Replace the module’s backup battery every 2 years to preserve configuration data during power outages. Avoid exposing **IS210MACCH1AFG** to direct steam or oil mist, and ensure the turbine enclosure maintains proper ventilation to stay within the operating temperature range.

IS210MACCH1AFG

Service and Guarantee Commitment

GE General Electric provides a 36-month quality guarantee for the **IS210MACCH1AFG**, covering manufacturing defects, processor failures, and communication interface issues under normal operating conditions. Our global technical support team offers 24/7 assistance, including remote commissioning guidance, firmware updates, and on-site service for critical turbine control systems. Customers receive access to GE’s Turbine Control Studio software and technical documentation for the **IS210MACCH1AFG** throughout the guarantee period. For power plant clients with priority service contracts, we ensure 72-hour replacement of defective modules to minimize turbine downtime—reflecting our commitment to supporting reliable power generation worldwide.