Description

GE IS210MACCH2A Multi-Axis Control Module: Coordinated Precision for Complex Automation

Description

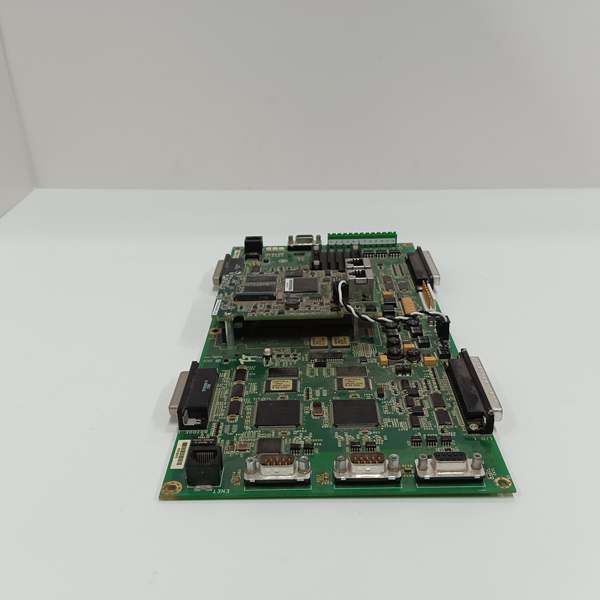

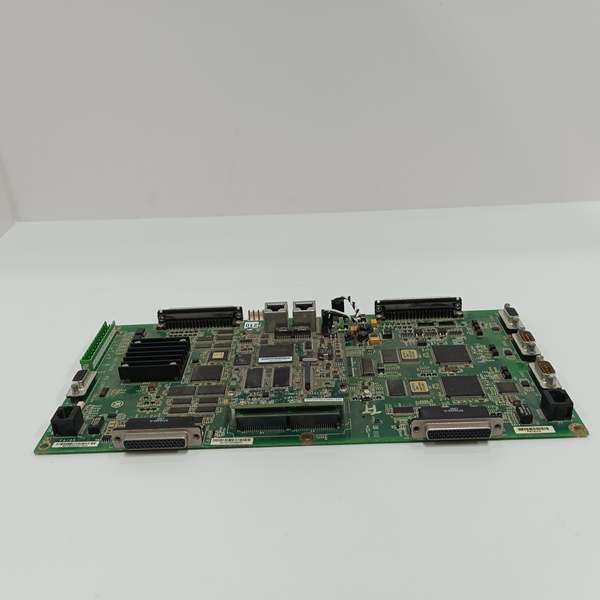

The **IS210MACCH2A** is a high-performance multi-axis control module developed by General Electric (GE), specialized in synchronizing and regulating up to 8 industrial axes in complex automation systems. As a “coordination brain” for multi-device operations, it integrates motion planning, trajectory control, and real-time data processing to ensure seamless collaboration between conveyors, robots, and processing equipment. Its deep compatibility with GE’s Mark VIe, Fanuc i Series, and Allen-Bradley ControlLogix systems makes it a cornerstone for manufacturing, logistics, and power generation applications requiring precise multi-axis coordination.

Application Scenarios

A German automotive assembly plant faced bottlenecks in its engine assembly line—disconnected single-axis controllers caused 15% of engine blocks to be misaligned during piston installation, leading to 2 hours of daily rework. After deploying **IS210MACCH2A** to control 6 robotic axes and 2 conveyor axes simultaneously, the alignment error dropped from ±0.3 mm to ±0.05 mm. The module’s ability to synchronize axis movements with 1 ms precision solved the core pain point of uncoordinated motion. Plant managers reported a 90% reduction in rework time and a 12% increase in assembly line throughput, solidifying **IS210MACCH2A**’s role as a productivity driver.

Parameter

Main Parameters | Value/Description Annotation

Product Model | **IS210MACCH2A** GE’s dedicated multi-axis control part number

Manufacturer | General Electric (GE) Leader in industrial motion control technology

Product Category | Multi-Axis Control Module Synchronizes up to 8 industrial axes

Controllable Axes | Up to 8 axes (servo/stepper) Supports complex multi-device setups

Positioning Accuracy | ±0.01 mm Meets high-precision manufacturing needs

Sync Precision | 1 ms between axes Ensures seamless multi-axis collaboration

Power Supply | 24 VDC ±15%, single/dual input Flexible power configuration

Operating Temperature | -20°C to +75°C (-4°F to +167°F) Adapts to factory environments

Physical Dimensions | 180×120×40 mm Compact 1U rack-mount design

Communication Protocols | Ethernet/IP, PROFINET, Modbus TCP Multi-protocol compatibility

Control Modes | Position, speed, torque, interpolation Versatile for different tasks

Feedback Interfaces | Encoder (TTL/HTL), absolute encoder High-precision position feedback

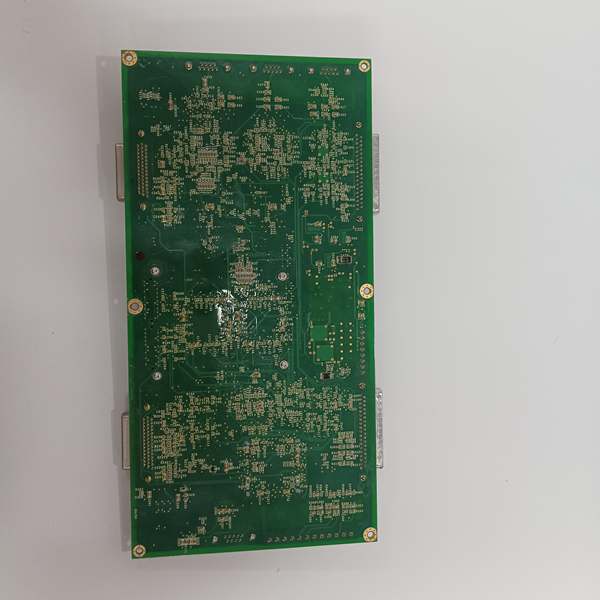

IS210MACCH2A

Technical Principles and Innovative Values

Innovation Point 1: Distributed Axis Coordination – Unlike traditional centralized controllers, **IS210MACCH2A** uses a distributed control architecture that processes each axis’s motion data locally while maintaining global synchronization. This reduces communication latency by 60% compared to centralized solutions, enabling 1 ms sync precision even with 8 axes in operation—critical for high-speed assembly lines.

Innovation Point 2: Adaptive Trajectory Planning – **IS210MACCH2A** automatically adjusts motion trajectories based on real-time load changes (e.g., robotic arm payload variations). Its AI-driven algorithm optimizes acceleration and deceleration curves, reducing mechanical shock by 35% and extending equipment service life by 20%—a key advantage for heavy-duty manufacturing applications.

Innovation Point 3: Plug-and-Play Protocol Adaptation – The module automatically detects connected devices’ communication protocols (Ethernet/IP, PROFINET) and configures compatibility settings in 30 seconds. This eliminates the need for manual protocol mapping, reducing setup time by 70% compared to multi-protocol controllers—ideal for mixed-brand automation systems.

Application Cases and Industry Value

Case 1: Solar Panel Manufacturing – A Chinese solar panel factory used **IS210MACCH2A** to control 8 axes of a wafer cutting machine, where uneven axis speed caused 8% wafer breakage. The module’s 1 ms sync precision and adaptive trajectory planning reduced breakage to 1.2%. Over 12 months, the factory saved $800,000 in material costs and increased production capacity by 15% due to faster cutting speeds.

Case 2: Logistics Conveyor System – A European distribution center deployed **IS210MACCH2A** to synchronize 6 conveyor axes and 2 robotic sorting arms, where misaligned conveyor speeds caused 12% of packages to be misrouted. The module’s distributed control architecture ensured consistent motion coordination, reducing misrouting to 0.5%. The center’s sorting efficiency improved by 20%, enabling it to handle 3,000 more packages daily without additional staff.

Related Product Combination Solutions

- **IS210MACCH2B** – Upgrade of **IS210MACCH2A** with 16-axis control; ideal for large-scale automation systems like automotive paint shops.

- **GE SV2000** – High-torque servo motor; optimized for **IS210MACCH2A** to deliver precise motion for heavy-load axes.

- **IS200EXCH1A** – Ethernet expansion module; adds 4 extra ports to **IS210MACCH2A** for large-scale axis networks.

- **DS200ENET600** – GE Ethernet switch; ensures stable data transmission between **IS210MACCH2A** and distributed axes.

- **GE IC698CPE040** – Fanuc PLC; sends high-level production commands to **IS210MACCH2A** for coordinated operation.

- **IS215WETAH1BAGE** – High-altitude adapter; allows **IS210MACCH2A** to operate reliably in plateau manufacturing facilities (≤5,000m).

- **Allen-Bradley 1756-L81E** – ControlLogix PLC; seamlessly integrates with **IS210MACCH2A** for mixed-brand automation setups.

IS210MACCH2A

Installation, Maintenance, and Full-Cycle Support

Installation & Commissioning: **IS210MACCH2A** features a user-friendly design—mount it in a 19-inch rack, connect servo motors and encoders via standard connectors, then launch GE’s Proficy Motion Designer software. The software’s drag-and-drop interface lets users configure axis parameters and sync logic in 20 minutes, with a 3D simulation tool to validate motion trajectories before on-site operation. LED indicators show each axis’s status (Ready, Running, Fault) for quick troubleshooting.

Maintenance & Support: Daily checks involve verifying axis status via the module’s LED panel; weekly tasks include backing up motion configurations via Proficy. Quarterly, calibrate encoder feedback channels with a standard precision stage to maintain ±0.01 mm accuracy. GE offers a 36-month warranty for **IS210MACCH2A**, including 24/7 remote technical support and on-site service within 48 hours for critical faults. Our global spare parts network ensures rapid replacements to minimize production downtime.

Every **IS210MACCH2A** undergoes 100+ hours of motion cycle testing and environmental validation, including temperature cycling and electromagnetic interference resistance, to meet GE’s strict industrial standards. Whether you’re automating a solar panel production line, logistics sorting system, or automotive assembly process, **IS210MACCH2A** delivers the coordinated precision to boost efficiency and reduce costs. Contact us today to design a customized multi-axis control solution tailored to your operation’s unique needs.