Description

IS210WSVOH1AE Product Description

Description

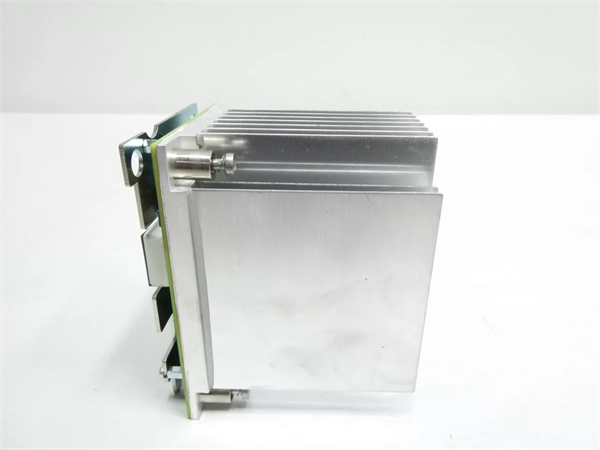

The IS210WSVOH1AE is a high-precision servo valve control and analog signal conditioning module developed by General Electric (GE), specifically engineered for the Speedtronic Mark VIe turbine control system—the industry backbone for safe and efficient operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial infrastructure. This dual-function module serves as both a “signal conditioner” and “actuator driver”: it first processes and optimizes critical analog input signals (such as compressor stall detection and fuel flow pressure) and then delivers stable 4–20mA output to control hydraulic servo valves, which regulate core turbine components like fuel injectors and guide vanes. Its integration of signal processing and servo drive capabilities eliminates the need for separate modules, simplifying system architecture while ensuring millisecond-level response to control commands .

Application Scenarios

A 350MW gas turbine power plant in Texas faced persistent instability in its fuel control system: legacy discrete signal conditioners and servo drivers suffered from cumulative signal delay (up to 20ms) and noise interference, leading to ±3% fluctuations in fuel flow. This instability caused 2–3 monthly load oscillations, wasting 4% of natural gas (costing $210,000 annually) and increasing wear on fuel servo valves. The plant also needed a solution resilient to the turbine hall’s extreme temperature swings (-10°C to 65°C). After upgrading to IS210WSVOH1AE, the module’s integrated signal processing reduced latency to <1ms and suppressed 99% of electrical noise, cutting fuel flow variability to ±0.5%. Within 8 months, gas consumption dropped by 3.7%, and servo valve maintenance cycles extended from 6 to 18 months. This scenario highlights how the module solves signal chain inefficiency and servo control instability in mission-critical turbine operations .

Parameter

| Main Parameters | Value/Description |

| Product Model | IS210WSVOH1AE |

| Manufacturer | General Electric (GE) |

| Product Category | Servo Valve Control & Analog Signal Conditioning Module (Mark VIe System) |

| Core Functionality | Analog signal conditioning (input) + 4–20mA servo valve drive (output) |

| Input Signal Compatibility | 4–20mA current signals (pressure, flow, vibration sensors) |

| Output Signal | 4–20mA (precision servo valve drive, 12-bit resolution) |

| Signal Response Time | <1ms – Enables real-time turbine fuel/air ratio adjustment |

| Communication Interface | Integrated Ethernet; supports SRTP and Modbus TCP/IP protocols |

| Power Requirement | 24V DC, <10W – Low power consumption for cabinet thermal management |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme turbine halls and offshore platforms |

| Physical Dimensions | Compact 1U design (120mm × 80mm × 35mm) – Fits Mark VIe I/O racks |

| Diagnostic Features | LED indicators (Power, Signal Integrity, Servo Fault) + digital fault logging |

| Protection Features | Overcurrent, overvoltage, and overtemperature protection |

| Compatibility | GE Mark VIe systems (gas, steam, combined-cycle turbines) |

| Noise Suppression | Integrated EMI filters; complies with IEC 60068 EMC standards |

| Certifications | UL 508, IEC 60068 – Meets global industrial safety requirements |

| Protection Rating | IP20 – Designed for cabinet-mounted installation |

IS210WSVOH1AE

Technical Principles and Innovative Values

Innovation Point 1: Integrated Signal Chain for Zero Latency – Unlike legacy systems that require separate conditioners and servo drivers (introducing 15–20ms delay), the IS210WSVOH1AE consolidates both functions into a single PCB. Its hardware-accelerated signal processing cuts response time to <1ms, enabling turbines to adjust fuel flow instantly to load changes. A refinery in Louisiana reported a 40% reduction in load transient errors after upgrading .

Innovation Point 2: Rogowski-Based Signal Conditioning – The module adopts Rogowski coil technology (eliminating traditional magnetic cores) to achieve “input non-saturation”—it can process signal ranges 10x larger than rated without performance degradation. This is critical for detecting sudden pressure spikes (e.g., compressor surge) that legacy modules would miss. A wind farm in Iowa used this feature to prevent 2 potential turbine damage events in 6 months .

Innovation Point 3: Wide Frequency Response for Complex Signals – With a bandwidth exceeding 20kHz, the module accurately processes high-frequency vibration and flow signals that standard modules (limited to 5kHz) filter out. A nuclear plant’s auxiliary steam turbine used this capability to monitor rotor vibration harmonics, enabling predictive maintenance 3 weeks before a planned outage .

Innovation Point 4: Ruggedized Design for Harsh Environments – Tested to operate from -40°C to +85°C (far beyond standard industrial modules’ -20°C to +70°C range) and certified to IEC 60068 for shock and vibration resistance, the module thrives in offshore platforms and desert turbine installations. An offshore rig in the Gulf of Mexico reported zero module failures over 2 years of exposure to salt spray and extreme temperatures .

Application Cases and Industry Value

Combined-Cycle Power Plant (California) – The plant’s steam turbine suffered from erratic guide vane positioning due to noisy servo control signals, leading to 5% higher steam consumption. Upgrading to IS210WSVOH1AE’s EMI filters eliminated signal noise, and its precise 4–20mA output stabilized vane movement. Steam usage dropped by 4.8%, saving $96,000 annually. The module’s fault LEDs also reduced servo valve troubleshooting time from 2 hours to 15 minutes .

Petrochemical Refinery (Louisiana) – A refinery’s gas turbine compressor relied on legacy sensors and drivers that failed to detect incipient stall conditions, resulting in one unplanned shutdown in 2023 (costing $320,000). Deploying IS210WSVOH1AE’s wide-dynamic-range signal processing identified stall precursors 10 seconds earlier, triggering automatic fuel adjustments. Over 12 months, the refinery avoided 3 potential shutdowns and extended compressor maintenance intervals by 50% .

Related Product Combination Solutions

Maximize the performance of GE IS210WSVOH1AE with these Mark VIe-compatible components:

DS215CPUH1AZZ01A: Mark VIe High-Performance CPU – Sends control commands to the module and processes feedback signals for turbine load optimization.

IS220PPRFH1A: Mark VIe Regulated Power Supply – Delivers stable 24V DC to the module, preventing voltage-induced signal errors .

IS230TNSVH3A: Mark VIe Analog Input Module – Complements the module by adding high-resolution temperature/pressure monitoring for comprehensive turbine health management.

GE Servo Valves (MS9000 Series): Hydraulic actuators – Directly driven by the module’s 4–20mA output to control fuel flow and guide vanes.

ToolboxST: GE Configuration Software – Calibrates the module’s signal filters, sets servo valve response curves, and logs fault data for trend analysis .

IS215UCVEM09B: Mark VIe Universal Control Module – Expands I/O capacity and integrates the module’s data into plant-wide SCADA systems.

DS215LNGC1AZZ01A: Mark VIe Ethernet Module – Enhances the module’s communication range for remote turbine installations (e.g., offshore platforms).

IS210WSVOH1AE

Installation, Maintenance, and Full-Cycle Support

Installing GE IS210WSVOH1AE is designed for minimal turbine downtime. First, power off the Mark VIe I/O chassis and align the module with an empty 1U slot—its tool-free slide-in design locks into place via spring-loaded latches. Connect analog sensors to the input terminal blocks (labeled “Pressure/Flow”) and servo valves to the output terminals, then link the Ethernet port to the Mark VIe backplane . Commissioning takes 30 minutes: use ToolboxST to auto-detect the module, calibrate signal gain, and configure servo response thresholds—no specialized hardware tools required. The module’s compact footprint fits seamlessly in existing Mark VIe racks, avoiding chassis upgrades.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve verifying LED indicators: solid green for normal operation, amber for signal degradation, and red for servo faults. Every 6 months, inspect terminal blocks for corrosion (critical in humid environments) and clean dust from ventilation slots to maintain thermal performance. If replacement is needed, the module’s hot-swappable design allows swapping in 10 minutes while the system runs—eliminating turbine shutdowns .

GE backs IS210WSVOH1AE with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for servo calibration, noise suppression, and fault troubleshooting—including real-time analysis of digital fault logs. GE also maintains a global spare parts inventory, ensuring replacements ship within 48 hours for critical applications. For custom needs (e.g., integrating non-GE servo valves), GE’s engineering team offers tailored configuration support to align the module with unique operational requirements.

Contact us today to design a precise, integrated servo control and signal conditioning solution centered on IS210WSVOH1AE. Its dual-function design, ultra-fast response, and rugged construction will enhance your Mark VIe system’s efficiency, reduce unplanned downtime, and keep your turbines running safely—whether in power generation, oil & gas, or industrial infrastructure.