Description

GE IS215ISBBH1A Mark VIe Intelligent Safety & Bypass Control Module

Product Overview

The IS215ISBBH1A is an intelligent safety and bypass control module developed by GE, exclusively designed for the Mark VIe turbine control system to ensure turbine safe operation and flexible bypass management. As a core component in the turbine safety interlock system, it integrates multi-channel safety signal acquisition, logic judgment, and bypass control output—realizing closed-loop management of critical safety interlocks (e.g., overspeed, high vibration, low oil pressure) and bypass logic (e.g., startup bypass, load rejection bypass). Unlike conventional safety relays, it features programmable logic and seamless Mark VIe integration, making it a critical safety barrier for gas, steam, and combined-cycle turbines in power generation, oil & gas, and industrial sectors.

What distinguishes IS215ISBBH1A from traditional safety control components is its turbine-specific intelligent logic and SIL 3 certification. It processes 16-channel safety input signals (e.g., speed, vibration, oil pressure) with a response time of ≤10 ms, triggering pre-set safety actions (e.g., turbine trip, valve closure) or bypass logic (e.g., activate startup bypass valve) based on programmable interlock rules. The module supports online logic modification without system shutdown and records all safety events with timestamp (precision to 1 ms) for incident traceability. Currently available as off-the-shelf stock with 3-5 days delivery, it retrofits seamlessly into existing Mark VIe systems, complying with international safety standards (IEC 61508 SIL 3) to minimize accident risks.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS215ISBBH1A |

| Manufacturer | GE (General Electric) |

| Compatible Systems | GE Mark VIe Turbine Control System (Firmware ≥v9.5) |

| I/O Specifications | 16-channel safety input (DI: 24 VDC; AI: 4-20 mA); 8-channel control output (DO: 24 VDC; AO: 4-20 mA) |

| Core Functions | Turbine safety interlock; bypass logic control; event recording; online logic editing; fault self-diagnosis |

| Safety Performance | Response time ≤10 ms; IEC 61508 SIL 3 certified; fault tolerance (1oo2D architecture) |

| Trigger Modes | Safety signal threshold breach; manual bypass request; system mode switch (startup/operation/shutdown) |

| Communication Interfaces | Mark VIe COREBUS, Ethernet/IP, Modbus TCP, OPC UA |

| Operating Environment | -20°C to +70°C (-4°F to +158°F); Humidity: 5-95% (non-condensing); Altitude ≤3,000 meters |

| Power Supply | 24 VDC ±15%; Dual redundant power input; 1.5 A typical current |

| Physical Dimensions | 177.8 mm (W) × 127 mm (H) × 50.8 mm (D); 19-inch rack mount (1U) |

| Certifications | CE, UL, IEC 61508 (SIL 3), IEC 61010-1, ISO 9001 |

IS215ISBBH1A

Main Features and Advantages

SIL 3 Safety Certification & Fault-Tolerant Design: IS215ISBBH1A meets IEC 61508 SIL 3 standards, adopting a 1oo2D (1 out of 2 with diagnostics) redundant architecture for safety inputs. Dual-core processors perform logic calculations simultaneously, with a diagnostic coverage rate of ≥99%. For a 300 MW steam turbine, this ensures that overspeed signals (≥3300 RPM) trigger a trip command within 8 ms, avoiding catastrophic failures—far exceeding the response time of traditional relays (≥50 ms).

Turbine-Specific Intelligent Interlock Logic: Pre-loaded with 10+ turbine safety interlock templates (e.g., gas turbine overspeed protection, steam turbine low vacuum trip), the module supports custom logic editing via GE Proficy software. It can realize complex interlock relationships (e.g., “trip only when both high vibration and low oil pressure occur”) to reduce false trips. A 200 MW combined-cycle plant using this module reduced false trip rates by 80% compared to legacy safety systems.

Flexible Bypass Control for Multi-Scenarios: It integrates startup bypass, maintenance bypass, and emergency bypass logic. During turbine startup, it automatically activates the bypass valve to control steam pressure, avoiding turbine overloading; during maintenance, authorized personnel can enable the maintenance bypass via password to perform tests without triggering trips. A 150 MW gas turbine plant shortened startup time by 30 minutes per startup using its intelligent bypass function.

High-Precision Event Recording & Traceability: The module records all safety events (input signal changes, output actions, logic triggers) with 1 ms timestamp accuracy, storing up to 100,000 events in non-volatile memory (data retention for 10 years without power). When a turbine trip occurs, operators can quickly trace the cause via event logs, reducing root-cause analysis time by 60%. The logs support export to CSV format for compliance reporting.

Seamless Mark VIe Integration & Online Maintenance: Connecting directly to the Mark VIe COREBUS, it shares safety status and bypass information with the main control system in real time. Logic modifications and parameter adjustments can be completed online without shutting down the turbine, eliminating unplanned downtime. A coal-fired power plant retrofitting this module avoided 2 days of shutdown, saving $500,000 in production losses.

High-Precision Pressure Measurement: Equipped with a 24-bit ADC, IS215PMVPH1A delivers ±0.02% FS accuracy across its 0-10000 psi range—outperforming generic modules (±0.1% FS). It supports both analog and HART-enabled pressure sensors, with built-in sensor drift compensation for long-term stability. For a 300 MW gas turbine, this ensures fuel pressure measurements are consistent within 0.1 psi, enabling precise fuel flow control and reducing emissions by up to 3%.

Turbine-Optimized PID Control: The module’s PID logic is pre-calibrated for turbine valves (e.g., fuel control valves, steam stop valves), with anti-windup and rate-limiting features to prevent valve overshoot. Unlike generic PID controllers, it responds to pressure changes in 50 ms—critical for load transients. A 150 MW steam turbine using this module reduced pressure fluctuations during load changes from ±5% to ±1.5%, improving steam quality and extending turbine life.

Seamless Mark VIe Integration: Connecting directly to the Mark VIe COREBUS without gateways, it shares pressure data and valve status with the main control system in real time. Its parameters (setpoints, PID gains) are configurable via GE Proficy software, and it supports hot-swapping for maintenance without system shutdown. A combined-cycle plant retrofitting from legacy controllers reduced integration time by 60% compared to third-party modules.

Safety & Reliability (SIL 2 Certified): Meeting IEC 61508 SIL 2 standards, IS215PMVPH1A includes dual-channel pressure monitoring and automatic valve fail-safe modes (e.g., close on power loss). For offshore gas turbines, this provides an extra layer of safety—detecting high fuel pressure and closing the valve within 100 ms to prevent over-pressurization and potential explosions.

Application Field

Gas Turbine Overspeed Protection: A 250 MW gas turbine plant in California deployed IS215ISBBH1A to replace legacy overspeed relays. During a load rejection test, the module detected an overspeed signal (3350 RPM) and triggered the fuel cutoff valve within 9 ms, preventing turbine damage. The event log clearly recorded the signal change process, providing reliable data for the test report.

Steam Turbine Low Oil Pressure Trip Control: A 400 MW coal-fired power plant in Shanxi, China, used IS215ISBBH1A to monitor lube oil pressure. When a oil pump failure caused pressure to drop to 0.08 MPa (setpoint: 0.1 MPa), the module triggered a turbine trip and activated the standby oil pump simultaneously. The fault self-diagnosis function immediately identified the faulty pump, guiding maintenance personnel to repair it within 2 hours.

Combined-Cycle Plant Startup Bypass Management: A 600 MW combined-cycle plant in Florida integrated IS215ISBBH1A into its Mark VIe system. During startup, the module automatically adjusted the bypass valve opening according to steam temperature and pressure, ensuring the turbine inlet parameters met requirements. This reduced startup fuel consumption by 8% and shortened the startup-to-grid-connection time from 4 hours to 2.5 hours.

Offshore Turbine Emergency Safety Control: A North Sea offshore gas turbine platform used IS215ISBBH1A for emergency safety control. When a storm caused severe vibration (exceeding 8 mm/s), the module triggered a controlled shutdown and activated the fire suppression system. The dual redundant power supply ensured the module remained operational during a partial power failure, avoiding offshore accidents.

Gas Turbine Fuel Control: A 200 MW gas turbine plant in Texas replaced legacy pressure controllers with IS215PMVPH1A to regulate natural gas supply pressure. The module’s precise measurement (±0.05 psi) and fast PID response reduced fuel pressure fluctuations by 70%, cutting NOx emissions by 4% and improving fuel efficiency by 1.2%—saving $150,000 annually in fuel costs.

Steam Turbine Inlet Pressure Regulation: A 400 MW coal-fired power plant in Germany deployed IS215PMVPH1A to control steam inlet pressure for its steam turbine. The module’s SIL 2 certification met safety requirements, while its drift compensation maintained accuracy over 12 months without recalibration. During load changes, steam pressure deviations were reduced from ±3 bar to ±0.5 bar, extending boiler tube life by 15%.

Offshore Compressor Pressure Control: A North Sea offshore platform used IS215PMVPH1A to regulate discharge pressure of a gas compressor driven by a 50 MW turbine. The module’s HART communication enabled remote sensor diagnostics, while its fail-safe valve control prevented over-pressurization during a sensor fault. This eliminated 3 unplanned shutdowns annually, saving $800,000 in production losses.

Related Products

IS215ISBBH1B: Enhanced variant of IS215ISBBH1A with 24 input channels and 12 output channels, for large-scale multi-turbine systems .

GE DS200TCQAG1A: Turbine speed monitoring module, pairs with IS215ISBBH1A to provide high-precision overspeed detection .

IS215WETAH1BAGE: High-altitude I/O module, extends IS215ISBBH1A’s application to plateau regions (≤5,000 meters) .

IS200EXCH1A: Ethernet expansion module, enables IS215ISBBH1A to upload safety event logs to GE Proficy Cloud .

GE HMI3000: Safety-specific HMI, used with IS215ISBBH1A for bypass operation authorization and safety status monitoring .

IS215PMVPH1B: Enhanced variant with 6 pressure inputs and 4 valve outputs, for large-scale turbine systems .

GE PT2000 Pressure Transducer: HART-enabled sensor optimized for IS215PMVPH1A, delivering 0-5000 psi measurements with ±0.01% accuracy .

IS215WETAH1BAGE: High-altitude I/O module, pairs with IS215PMVPH1A to extend pressure control to plateau regions (≤5,000 meters) .

IS200EXCH1A: Ethernet expansion module, enables IS215PMVPH1A data transmission to GE Proficy Cloud for remote monitoring .

IS215ISBBH1A

Installation and Maintenance

Pre-Installation Preparation

Verify Mark VIe firmware ≥v9.5 (required for SIL 3 logic compatibility) and ensure dual redundant 24 VDC power supply with stable grounding. Confirm safety input signal types (DI/AO) and output device compatibility (valve/relay). Prepare tools: anti-static wristband, torque screwdriver (0.5-1.0 N·m), multimeter, GE Proficy Logic Developer software (v9.0+), and safety signal simulator.

Installation Steps

Mount IS215ISBBH1A in the 19-inch control rack, ensuring sufficient heat dissipation space (≥50 mm on both sides); torque front screws to 0.8 N·m.

Connect dual redundant power cables (24 VDC) and ground wires; ensure polarity is correct to avoid module damage.

Wire safety input signals (speed, vibration, oil pressure) to input channels; wire control outputs (trip relay, bypass valve) to output channels.

Connect COREBUS cable to Mark VIe STCA board; configure module IP address and communication parameters via Proficy software.

Import or edit safety interlock/bypass logic via Proficy Logic Developer; perform logic simulation to verify correctness.

Calibrate safety input thresholds (e.g., overspeed setpoint: 3300 RPM) and test output actions (e.g., trip valve closure) using a signal simulator.

Maintenance Recommendations

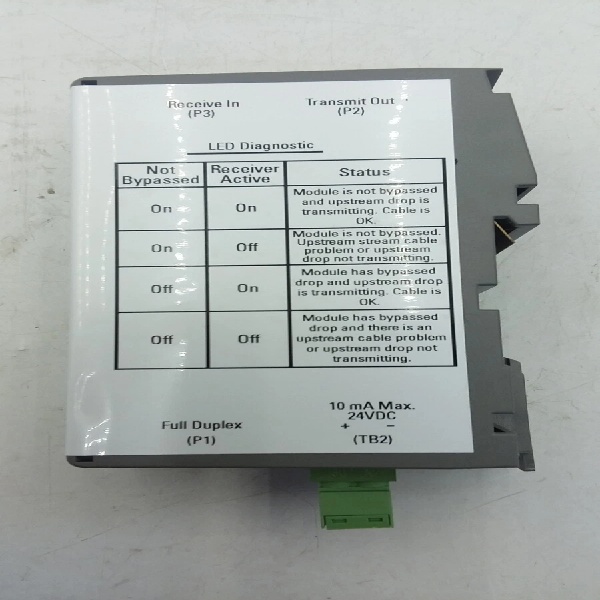

Daily: Check power supply status (dual power indicator); monitor safety status LED (green: normal, red: fault); review real-time safety signals via HMI.

Weekly: Test logic trigger conditions (e.g., simulate low oil pressure) to verify output actions; back up safety event logs to external storage.

Monthly: Perform fault self-diagnosis via Proficy software; check cable connections for looseness or corrosion; verify password authorization for bypass operations.

Quarterly: Calibrate input signal accuracy using a standard simulator; update module firmware (if provided by GE); re-verify SIL 3 logic integrity.

Troubleshooting: If a false trip occurs, first check the event log for signal anomalies; for communication failures, verify COREBUS connection and IP settings; for output failures, test the output channel with a multimeter .

Pre-Installation Preparation

Verify Mark VIe firmware ≥v9.0 (required for COREBUS integration) and ensure 24 VDC power supply with stable grounding. Confirm pressure sensor compatibility (analog/HART) and valve actuator signal type (4-20 mA/0-10 VDC). Prepare tools: anti-static wristband, torque screwdriver (0.5-1.0 N·m), precision multimeter, and GE Proficy software (v8.5+).

Installation Steps

Mount IS215PMVPH1A in the 19-inch control rack, securing with front screws (torque to 0.8 N·m).

Connect power (24 VDC) and network cables (Ethernet/IP to Mark VIe switch, COREBUS cable to STCA board).

Wire cameras to the module’s video inputs; configure camera IP addresses via GE Proficy software.

Set up data tags (e.g., RPM, vibration) for synchronization and define trigger thresholds (e.g., vibration > 5 mm/s).

Calibrate pressure inputs using a precision test pump; set PID gains and valve output limits via Proficy software.

Maintenance Recommendations

Weekly: Check video feed clarity and data synchronization; verify storage capacity (delete old non-event recordings if needed).

Monthly: Test pressure setpoint tracking and valve response; verify alarm logic (high/low pressure) triggers correctly.

Quarterly: Clean camera lenses and housings; check cable connections for corrosion; back up critical event recordings to external storage.

Troubleshooting: If pressure measurements drift, calibrate inputs first; for valve overshoot, adjust PID gain parameters via Proficy software .

Product Guarantee

Genuine IS215ISBBH1A modules come with a 36-month warranty (extended for safety-critical components), covering manufacturing defects, SIL 3 performance compliance, logic operation accuracy, and communication functionality. Off-the-shelf units include 3-5 days delivery, free on-site integration support (first 60 days), and SIL 3 certification documentation. Extended warranty options (up to 5 years) include annual safety logic verification, firmware updates, and priority technical support. GE offers a “safety performance validation” program—providing on-site testing to ensure the module meets safety response time and fault tolerance requirements within 30 days of installation, or offering a full replacement.

Genuine IS215PMVPH1A modules come with a 24-month warranty, covering manufacturing defects, pressure measurement accuracy, and PID control functionality. Off-the-shelf units include 3-5 days delivery and free on-site calibration support for the first 60 days. Extended warranty options (up to 4 years) include annual precision calibration and SIL 2 compliance verification. GE offers a “performance guarantee” program—ensuring the module meets pressure control accuracy specs within 30 days of installation, or providing a full replacement.