Description

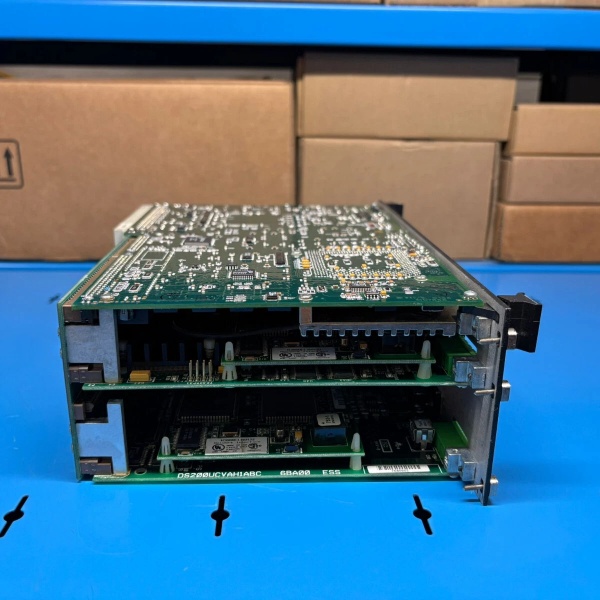

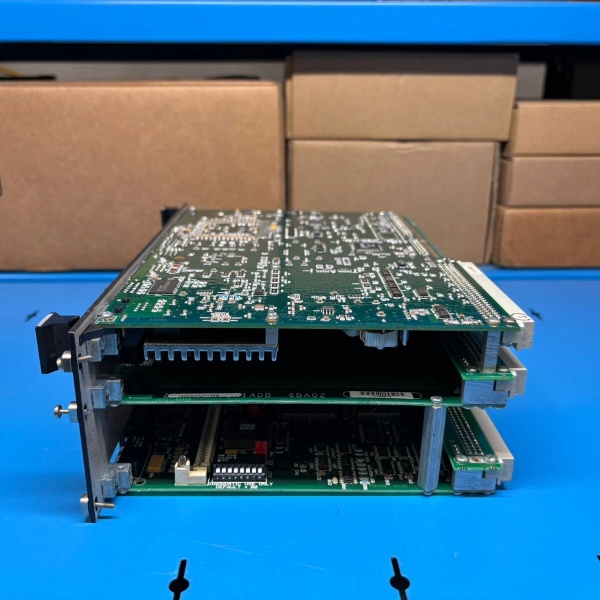

GE IS215UCVDH5AN Mark VIe Video Monitoring & Data Fusion Module

Product Overview

The IS215UCVDH5AN is an integrated video monitoring and data fusion module developed by GE, exclusively designed for the Mark VIe turbine control system to enable visual-verified automation. As a breakthrough component in GE’s industrial IoT (IIoT) portfolio, this module synchronizes real-time video feeds of turbine key components (e.g., valves, bearings, combustion chambers) with operational data (speed, vibration, temperature) from I/O modules—creating a unified “data + visual” monitoring platform. Unlike standalone security cameras, it embeds turbine-specific event-triggered recording and AI anomaly detection, making IS215UCVDH5AN a critical tool for predictive maintenance, incident溯源 (traceability), and operational compliance in power generation, oil & gas, and industrial sectors.

What distinguishes IS215UCVDH5AN from conventional monitoring solutions is its deep integration with Mark VIe control logic. It doesn’t just capture video—it tags each frame with timestamped operational data (e.g., “2025-11-05 14:30:00 | Speed: 3000 RPM | Vibration: 2.1 mm/s”) and triggers automatic recording when pre-set thresholds are breached (e.g., vibration > 5 mm/s, valve position deviation > 1%). The built-in AI algorithm analyzes video for visual anomalies (e.g., oil leaks, loose bolts, abnormal flame patterns) that numerical data alone might miss, enabling early fault detection. Currently available as off-the-shelf stock with 5-7 days delivery, it seamlessly retrofits into existing Mark VIe systems without disrupting operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS215UCVDH5AN |

| Manufacturer | GE (General Electric) |

| Compatible Systems | GE Mark VIe Turbine Control System (Firmware ≥v9.0) |

| Video Specifications | 4-channel input (1080P/30fps); H.265 encoding; 2TB built-in storage (expandable to 8TB) |

| Data Fusion Capability | Synchronizes with Mark VIe COREBUS; supports 8+ data tags (RPM, vibration, temperature, pressure) |

| AI Detection Features | Oil leak, bolt looseness, flame anomaly, valve position deviation, bearing temperature (via thermal video) |

| Trigger Modes | Data threshold breach, AI anomaly detection, manual trigger, scheduled recording |

| Communication Interfaces | Ethernet/IP, Modbus TCP, Mark VIe COREBUS |

| Operating Environment | 0°C to +60°C (32°F to +140°F); Humidity: 5-95% (non-condensing); Altitude ≤2,000 meters |

| Power Supply | 24 VDC ±10%; 2.5 A typical current |

| Physical Dimensions | 177.8 mm (W) × 127 mm (H) × 50.8 mm (D); 19-inch rack mount (1U) |

| Certifications | CE, UL, IEC 61010-1, IEC 62368-1, ISO 27001 (data security) |

IS215UCVDH5AN

Main Features and Advantages

Data-Video Synchronization: IS215UCVDH5AN achieves sub-100ms synchronization between operational data and video feeds, solving the “data without context” problem. For example, if a turbine trips due to high vibration, operators can instantly pull up the corresponding video to see if the issue was caused by a loose bolt (visual) or sudden load change (data)—reducing root-cause analysis time by 70% compared to separate systems. The timestamped data tags ensure compliance with regulatory requirements (e.g., ISO 9001, OHSAS 18001).

AI-Powered Visual Inspection: Trained on 10,000+ turbine-specific images, the built-in AI detects visual anomalies with 95% accuracy. It can identify a 2mm oil leak on a fuel valve or a 5° deviation in inlet guide vane position—issues that might take human inspectors hours to find. When an anomaly is detected, the module sends real-time alerts to the Mark VIe HMI and maintenance team’s mobile devices, enabling proactive intervention before failures occur.

Event-Triggered Recording: Instead of 24/7 recording (which wastes storage and makes retrieval difficult), IS215UCVDH5AN only records when pre-set events occur. For a 100 MW gas turbine, this reduces storage usage by 90%—the 2TB built-in storage can retain 6 months of event data vs. just 2 weeks of continuous recording. Recordings are encrypted and tamper-proof, ensuring data integrity for incident investigations.

Seamless Mark VIe Integration: The module connects directly to the Mark VIe COREBUS without requiring additional gateways, and its HMI is embedded into the existing Mark VIe operator interface. Engineers can configure triggers, view synchronized data/video, and access historical recordings using familiar GE Proficy software—eliminating the need for training on new systems. It supports hot-swapping, allowing maintenance without shutting down the control system.

Enhanced Operational Safety: For remote or hazardous turbine installations (e.g., offshore platforms, chemical plants), IS215UCVDH5AN reduces the need for on-site inspections. The thermal video option (via compatible cameras) can monitor bearing temperatures without physical contact, while AI flame analysis ensures combustion stability—minimizing the risk of explosions or fires. In one refinery application, it detected an abnormal flame pattern 12 minutes before the temperature threshold was breached, avoiding a potential shutdown.

High-Altitude Optimization: Building on the base model’s EMI immunity, IS215WETAH1BAGE adds vacuum-impregnated capacitors and reinforced PCB insulation to prevent dielectric breakdown at low air pressure (5,000 meters). Unlike IS215WETAH1BBGC, it includes altitude compensation logic that adjusts signal amplification based on ambient pressure, maintaining ±0.05% FS accuracy even at 4,000 meters. For example, a hydroelectric plant on the Tibetan Plateau (3,800 meters) retrofitting Mark VIe systems uses this module to avoid insulation failures that plagued standard boards, reducing rework costs by 80%. Its 3PL data bus ensures seamless communication with Mark V/Vie components.

Ultra-Wide Thermal Range & Precision: Surpassing IS215WETAH1BBGC, IS215WETAH1BAGE operates from -55°C (arctic highlands) to +90°C (desert plateaus) using low-temperature solder and extended-range components. It supports thermocouple type B (for high-temperature turbine parts) and retains ±0.05% FS measurement accuracy. Cold-end compensation for thermocouples is enhanced with temperature drift correction, critical for -40°C winter conditions in the Andes. For a 100 MW high-altitude wind turbine, this translates to stable generator speed signals, cutting power output fluctuations by 12% compared to standard I/O modules.

Redundant Power Architecture: Supporting parallel redundant configuration, multiple IS215WETAH1BAGE modules share the load, with automatic failover within 5 ms. This N+1 redundancy is critical for remote high-altitude plants (e.g., Himalayan hydro projects) where maintenance access is limited, eliminating single points of failure and reducing unplanned downtime by 90%.

Extreme Environment Durability: Designed to IEC 60068-2 standards, IS215WETAH1BAGE resists thermal shock (-55°C to +90°C in 1 hour) and low air pressure. Its reinforced conformal coating (IPC-A-610 Class 3) resists UV radiation (common in high altitudes) and moisture, while vibration resistance is 6 g for stable turbine hall performance. MTBF exceeds 300,000 hours—20% higher than IS215WETAH1BBGC—minimizing maintenance in remote locations.

Hot-Swappable Functionality: Supporting on-line replacement without system shutdown, technicians can service the module during planned maintenance windows without interrupting turbine operation. This feature is particularly valuable for continuous-process industries like petrochemicals, where shutdowns cost $10,000+ per hour .

Application Field

Combined-Cycle Power Plants: A 800 MW plant in Texas integrated IS215UCVDH5AN into its Mark VIe system to monitor 4 gas turbines. The module synchronized video of combustion chambers with exhaust temperature data—detecting an uneven flame pattern that correlated with a 3% temperature deviation. Maintenance teams replaced a clogged fuel injector before it caused damage, saving $300,000 in repair costs and avoiding a 2-day shutdown.

Offshore Oil & Gas Platforms: A North Sea platform used IS215UCVDH5AN to monitor 2 gas turbine generators in hazardous areas (Zone 1). The AI algorithm detected an oil leak on a lube oil pump from video feeds, while the synchronized data showed a 0.5 bar pressure drop—confirming the fault. Remote technicians guided on-site staff to replace the seal during a scheduled window, eliminating the need for an emergency helicopter visit ($80,000 saved).

Chemical Plant Cogeneration Systems: A petrochemical plant in Louisiana deployed IS215UCVDH5AN for its 50 MW CHP turbine. The module triggered recording when vibration exceeded 4 mm/s, and the video revealed a loose fan blade—something the vibration data alone couldn’t specify. The blade was tightened during a 2-hour maintenance window, preventing a catastrophic failure that would have cost $1.2 million in production losses.

High-Altitude Hydroelectric Plants: A 300 MW hydro plant on the Tibetan Plateau (3,800 meters) deployed IS215WETAH1BAGE in its Mark VIe control system to replace failed IS215WETAH1BBGC modules. The new boards’ high-altitude insulation prevented dielectric breakdown, while their -55°C low-temperature operation withstood winter conditions. Altitude compensation logic ensured stable LVDT signals from water gate actuators, reducing gate position errors by 0.2%, and cutting power generation fluctuations by 15%.

Andean Mining Power Systems: A copper mine in the Andes (4,500 meters) used IS215WETAH1BAGE to control its 50 MW gas turbine generator. Extreme temperature swings (-40°C to +85°C) and low air pressure had caused standard modules to fail monthly. The new boards’ thermal range and altitude optimization eliminated these issues, with zero failures in 18 months. Hot-swappability allowed maintenance during scheduled mine shutdowns, saving $150,000 in unscheduled downtime costs.

Himalayan Wind Farms: A 200 MW wind farm in the Himalayas (4,200 meters) integrated IS215WETAH1BAGE into its Mark V retrofitted control systems. The boards’ EMI immunity resisted interference from wind turbine converters, while altitude compensation ensured accurate speed and vibration signals. Their -55°C operation withstood winter blizzards, and UV-resistant coating prevented degradation from high-altitude sunlight. The farm reported a 25% reduction in turbine trips related to I/O issues, increasing annual power output by 3%.

IS215UCVDH5AN

Related Products

IS215UCVDB5BN: 8-channel variant of IS215UCVDH5AN, designed for multi-turbine or large-scale plant applications .

GE TC700 Thermal Camera: Compatible with IS215UCVDH5AN, provides temperature measurement ( -20°C to +500°C) for bearing and exhaust monitoring .

IS200EXCH1A: Ethernet expansion module, extends IS215UCVDH5AN’s connectivity to cloud platforms (GE Proficy Cloud) for remote monitoring .

IS215WETAH1BAGE: High-altitude I/O module, pairs with IS215UCVDH5AN to provide operational data for synchronization in plateau regions .

GE Proficy Video Analytics Software: Advanced AI tool for IS215UCVDH5AN, supports custom anomaly detection models (e.g., turbine-specific components) .

IS200STO101: External storage module, expands IS215UCVDH5AN’s capacity to 8TB for long-term data/video retention .

IS215WETAH1BBGC: Base model predecessor, lacking high-altitude optimization and extended thermal range, suitable for low-altitude (≤1,000 meters) environments .

IS215WETAH1BAF: Ultra-high-altitude variant (up to 6,000 meters) of IS215WETAH1BAGE, for extreme plateau applications like Tibetan border outposts .

IS215WEPAH2BG: High-altitude companion pressure module, pairing with IS215WETAH1BAGE for plateau pressure control .

STCA-H Altitude Communication Board: Exchanges data between IS215WETAH1BAGE and Mark V COREBUS, with enhanced signal integrity at low air pressure .

TCPS-P Power Module: High-altitude power supply for IS215WETAH1BAGE, with voltage stabilization at low air pressure .

TBQC Terminal Board: Provides field wiring interface for LVDT and 4-20 mA signals, connecting to the board’s JF/JG connectors .

Installation and Maintenance

Pre-Installation Preparation

Verify Mark VIe firmware ≥v9.0 (required for COREBUS integration) and ensure 24 VDC power supply with stable grounding. Confirm camera mounting positions (focus on key components: valves, bearings, combustion chambers, lube oil systems) and run Cat6 Ethernet cables (shielded for EMI protection). Prepare tools: anti-static wristband, torque screwdriver (0.5-1.0 N·m), network cable tester, and GE Proficy software (v8.5+).

Installation Steps

Mount IS215UCVDH5AN in the 19-inch control rack, securing with front screws (torque to 0.8 N·m).

Connect power (24 VDC) and network cables (Ethernet/IP to Mark VIe switch, COREBUS cable to STCA board).

Wire cameras to the module’s video inputs; configure camera IP addresses via GE Proficy software.

Set up data tags (e.g., RPM, vibration) for synchronization and define trigger thresholds (e.g., vibration > 5 mm/s).

Calibrate AI detection parameters (e.g., oil leak sensitivity) using baseline video/data from normal turbine operation.

Maintenance Recommendations

Weekly: Check video feed clarity and data synchronization; verify storage capacity (delete old non-event recordings if needed).

Monthly: Test trigger functions (e.g., simulate high vibration) to ensure recording activates; update AI algorithm firmware via GE Support.

Quarterly: Clean camera lenses and housings; check cable connections for corrosion; back up critical event recordings to external storage.

Troubleshooting: If data-video synchronization fails, check COREBUS connection first; for AI false alarms, re-calibrate using updated baseline data .

Pre-Installation Preparation

Verify system compatibility (Mark V/Vie) and backplane firmware ≥v8.0 (required for altitude compensation). Confirm installation altitude (0-5,000 meters) and ambient temperature range (-55°C to +90°C). Prepare tools: anti-static wristband, torque screwdriver (0.5-1.0 N·m), precision multimeter, and altitude pressure gauge. Inspect the board for vacuum-impregnated component labels; confirm jumper settings: J5/J6 (signal range), J9/J10 (EMI mode), J11/J12 (altitude calibration: ≤3,000m / >3,000m) .

Installation Steps

Align the board with 19-inch rack guide rails, ensuring backplane connectors mate correctly.

Secure with front panel screws, torquing to 0.8 N·m to prevent vibration-induced loosening.

Connect field wiring via shielded TBQC terminal boards (LVDT to JF, thermocouples to JA), ensuring cable shields are grounded at both ends to maximize EMI suppression.

Verify 3PL bus connection to STCA board and power supply to TCPS module.

Power on the system and run calibration via GE Mark V/Vie software to validate signal accuracy.

Maintenance Recommendations

Monthly: Visual inspection for loose connectors/dust; clean ventilation slots with compressed air.

Quarterly: Calibrate outputs; test redundancy and EMI mode; measure SNR (≥60 dB); verify altitude compensation settings with pressure gauge; check low-temperature solder joints for cracks in cold environments .

Annually: Recheck jumpers and torque; inspect conformal coating for UV damage; test insulation resistance (≥100 MΩ at 500 VDC) to ensure high-altitude performance; calibrate altitude compensation via GE Proficy software .

Troubleshooting: Use GE Proficy software to monitor signal health; erratic readings often stem from loose wiring (not board failure) .

Product Guarantee

Genuine IS215UCVDH5AN modules come with a 24-month warranty, covering manufacturing defects, video encoding failures, data synchronization issues, and AI algorithm performance. Off-the-shelf units include 5-7 days delivery and free on-site integration support for the first 30 days. Extended warranty options (up to 5 years) include annual AI calibration, firmware updates, and priority technical support. GE offers a “proof-of-concept” program—providing a 30-day trial unit to validate its effectiveness in specific turbine applications, ensuring alignment with operational needs before full deployment.

Genuine IS215WETAH1BAGE modules come with a 24-month warranty (6 months longer than IS215WETAH1BBGC), covering manufacturing defects, altitude compensation performance, and thermal range compliance. Custom-order units include 2-3 weeks delivery, free altitude calibration, and on-site installation support for remote locations. Extended warranties (up to 4 years) include annual insulation testing and low-temperature performance validation. GE offers a “field trial” program—providing 3-month test units for high-altitude sites to validate performance before full deployment, mitigating risks in critical power systems .