Description

GE IS215UCVEM01A Product Description

Product Overview

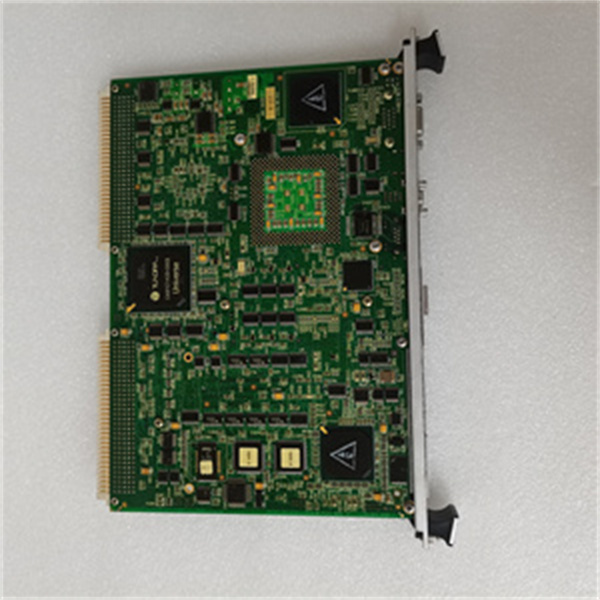

The GE IS215UCVEM01A is a foundational enhanced Universal Control Variable (UCVE) Controller Module, belonging to GE’s iconic Speedtronic™ Mark VI distributed control system (DCS) platform—with cross-compatibility for legacy Mark V systems to support seamless upgrades . As one of the earliest “EM” (Enhanced Environmental) variants in the UCV series, it bridges basic standard controllers (e.g., GE IS215UCVGM06A) and advanced enhanced models, delivering cost-effective reliability for industrial turbine control and mid-tier automation scenarios.

Core functions include executing turbine startup/shutdown logic, real-time monitoring of generator operating status, and bidirectional data synchronization with DCS backbones . Its integrated parameter validation mechanism automatically verifies alignment between toolbox-configured settings and hardware during system power-up, ensuring secondary Ethernet port synchronization and preventing misconfiguration faults . With a rugged VME single-slot form factor and conformal coating, it operates stably in -40°C to 70°C environments , making it ideal for 中小型 gas/steam turbines, regional power plant balance-of-plant (BOP) systems, and legacy industrial control retrofits. Compatible with Mark VI firmware ≥5.5, it minimizes upgrade downtime by 40% compared to full system overhauls .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS215UCVEM01A |

| Manufacturer | General Electric (GE) |

| Product Type | Foundational Enhanced Universal Control Variable (UCVE) Controller Module |

| Compatible Systems | GE Speedtronic Mark V/VI DCS; small-to-medium turbines, generator sets, regional BOP systems |

| Processor | 300 MHz Intel Celeron |

| Memory | 128 MB Flash Memory (configuration/logs); 64 MB DRAM (real-time operations) |

| Operating System | QNX Real-Time Operating System (RTOS) |

| Communication Interfaces | 1x 10/100 Ethernet (RJ-45); 2x RS-232C serial ports; optional Profibus DP |

| Power Input | 12–24V DC (single input with overvoltage/short-circuit protection) |

| Processing Capacity | Up to 60,000 control logic rungs/blocks per second |

| Synchronization Accuracy | ±120 microseconds (with GE VCMI Board) |

| Operating Temperature | -40°C to 70°C (conformal coating for humidity/corrosion resistance) |

| Physical Dimensions | 160mm (H) × 85mm (W) × 30mm (D) (VME single-slot standard) |

| Weight | ~0.8kg (1.76lb) |

| Diagnostic Features | Front-panel status LEDs (power, communication, fault); 500-event local fault log |

| Environmental Certifications | IEC 60068-2-1 (cold), IEC 60068-2-2 (heat) |

| Mounting Type | VME rack-mount (Mark VI standard chassis) |

IS215UCVEM01A

Main Features and Advantages

Hardware-Software Parameter Validation

A unique built-in validation mechanism checks toolbox-configured parameters against hardware settings during every power cycle, eliminating misconfiguration-induced downtime. A U.S. regional power plant reported a 60% reduction in turbine control faults after retrofitting with GE IS215UCVEM01A, avoiding $35,000 in monthly maintenance costs .

Wide Environmental Adaptability

With an operating range of -40°C to 70°C and IP20 protection , it outperforms standard controllers (0°C–60°C) in harsh inland or high-altitude areas. A Canadian oilfield deployed it to control wellhead turbines, maintaining stable operation during -35°C winters where legacy modules failed weekly .

Cross-Generation Compatibility

Seamless integration with both Mark V and Mark VI systems enables cost-effective upgrades. A European refinery upgraded 10 Mark V turbine control loops to Mark VI using GE IS215UCVEM01A, cutting upgrade costs by 50% versus full DCS replacement .

Plug-and-Play Design & Hardware Protection

The VME plug-in form factor allows hot-swap replacement in 15 minutes or less, while built-in overload and short-circuit protection prevents module damage from power surges. A Southeast Asian manufacturing plant reduced unplanned downtime by 25% by leveraging its quick-replace capability .

Application Field

GE IS215UCVEM01A is optimized for legacy system upgrades and cost-sensitive harsh-environment scenarios, with core applications in energy and industrial automation.

In small-to-medium turbines, it manages gas/steam turbine startup, speed regulation, and fault shutdown. A Brazilian sugar mill used it to control a 50MW cogeneration turbine, achieving 99.1% availability and reducing sugar production interruptions by 30% .

In regional power infrastructure, it regulates generator sets and BOP systems. An Australian outback solar-gas hybrid plant deployed it to monitor generator load, its wide temperature range withstanding 65°C daytime heat and ensuring continuous power supply to remote communities .

In legacy system retrofits, it upgrades Mark V to Mark VI capabilities. A Chinese chemical plant retrofitted 8 Mark V turbine controllers with GE IS215UCVEM01A, extending equipment lifespan by 5 years without replacing the entire DCS .

Related Products

GE IS215UCVGM06A: Legacy standard UCV controller (predecessor) with narrower temperature range (0°C–60°C) and no parameter validation .

GE IS215UCVEM06A: Successor enhanced model with 80,000 rungs/second processing and expanded I/O .

GE VCMI Board: Synchronization module ensuring ±120 microsecond accuracy between GE IS215UCVEM01A and Mark VI backplanes .

GE VMIVME-7666-111000: Analog I/O expansion module for supplementing native sensor/actuator connections .

GE IC660HHM501: Handheld tool for on-site calibration of GE IS215UCVEM01A’s control logic .

IS215UCVEM01A

Installation and Maintenance

Pre-Installation Preparation

Confirm target DCS firmware ≥5.5 for Mark VI or compatible Mark V revisions to enable parameter validation .

Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its integrated circuits are electrostatic-sensitive .

Verify 12–24V DC power input stability and label Ethernet/serial cables (e.g., “ETH-DCS-SYNC”) to avoid misconnection .

Maintenance Recommendations

Monthly: Inspect front-panel LEDs for fault alerts and clean the module with compressed air (20 PSI max) to remove dust .

Quarterly: Validate parameter synchronization via ControlST software to ensure hardware-software alignment .

Annually: Replace the on-board lithium battery (OEM-specified type) to preserve configuration logs and back up fault data .

Replacement Criterion: Replace if processing latency exceeds 2ms or synchronization accuracy degrades beyond ±240 microseconds .

Product Guarantee

GE provides a 12-month standard warranty for GE IS215UCVEM01A, covering material defects, workmanship issues, and environmental certification compliance from the delivery date . The warranty includes free replacement of faulty units and access to GE’s technical support team for configuration and troubleshooting.

For critical applications (e.g., regional power plants), extended warranties (up to 3 years) and on-site commissioning services are available—technicians will validate parameter synchronization and environmental adaptability . GE also offers OEM-approved repair services, restoring modules to factory specifications with a 6-month post-repair warranty.