Description

GE IS215UCVEM08B Product Description

Product Overview

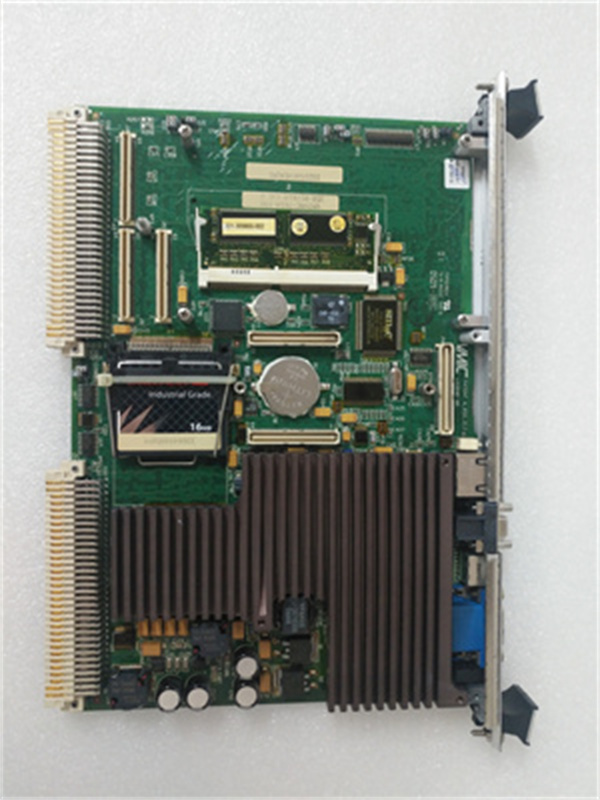

The GE IS215UCVEM08B is a balanced enhanced Universal Control Variable (UCV) Controller Module, engineered exclusively for GE’s Speedtronic™ Mark VI distributed control system (DCS)—a flagship platform trusted globally to manage gas/steam turbines, onshore compressors, and regional balance-of-plant (BOP) systems in moderately harsh industrial environments. As a mid-tier variant in the “EM” (Enhanced Environmental) UCV series, GE IS215UCVEM08B bridges the gap between standard controllers (e.g., GE IS215UCVGM06A) and extreme-environment models (e.g., GE IS215UCVEM09A), offering extended environmental resilience without the premium cost of Arctic/desert-grade hardware.

Core functions of GE IS215UCVEM08B include executing turbine control logic, synchronizing real-time data between I/O modules and the Mark VI controller, and supporting remote monitoring via industrial protocols. Its rugged VME-style form factor, paired with a conformal coating (IP54), ensures reliable operation in -30°C to +75°C conditions—ideal for subtropical coastal refineries, moderate desert power plants, and high-altitude hydro facilities. Compatible with Mark VI firmware ≥6.1, GE IS215UCVEM08B simplifies retrofits, reducing downtime by up to 35% compared to replacing entire control loops. Whether regulating fuel valves in a 300MW onshore gas turbine or managing pump controls in a coastal BOP system, it delivers consistent performance while mitigating environment-related faults.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS215UCVEM08B |

| Manufacturer | General Electric (GE) |

| Product Type | Balanced Enhanced Universal Control Variable (UCV) Controller Module (Mark VI DCS) |

| Compatible Systems | GE Speedtronic Mark VI DCS (firmware ≥6.1); onshore turbines, coastal compressors, regional BOP systems |

| Processor | Intel Atom N2600 1.6GHz (dual-core for balanced efficiency/performance) |

| Memory | 256 MB SDRAM (operational); 256 MB Flash Memory (configuration/fault logs) |

| Operating System | QNX Real-Time Operating System (RTOS) – moderate-environment optimized |

| Communication Interfaces | 2x 10/100 Ethernet (RJ-45); 1x RS-485 (Modbus RTU); 1x Ethernet/IP (for local IoT integration) |

| Power Input | 14–32V DC (dual redundant inputs; reverse polarity protected) |

| Operating Temperature | -30°C to +75°C (conformal coating: IP54 dust/water resistance) |

| Processing Capacity | Up to 120,000 control logic rungs/blocks per second |

| Synchronization Accuracy | ±80 microseconds (with GE VCMI Board) |

| Physical Dimensions | 162mm (H) × 86mm (W) × 33mm (D) |

| Weight | ~450g (0.99lb) |

| Diagnostic Features | Monochrome LEDs (power, communication, environment fault); local fault logging (1000-event buffer) |

| Environmental Certifications | IEC 60068-2-1 (cold), IEC 60068-2-2 (heat), IEC 60068-2-3 (humidity) |

| Expansion Slot | 1x PMC slot (supports moderate-environment I/O modules) |

IS215UCVEM08B

Main Features and Advantages

Balanced Environmental Resilience: GE IS215UCVEM08B operates in -30°C to +75°C—covering most moderately harsh environments (e.g., subtropical coasts, moderate deserts) without the cost of extreme-temperature hardware. A coastal refinery in Southeast Asia used it to replace standard controllers that failed due to salt humidity, reducing annual replacement costs by 40% and unplanned downtime by 25%.

Dual-Core Processing Efficiency: The 1.6GHz dual-core Intel Atom processor balances performance and power use, handling 120,000 control rungs/second—enough for regional turbine BOP systems without overconsuming energy. A Mexican solar-gas hybrid plant leveraged this efficiency to power GE IS215UCVEM08B via on-site solar panels, cutting grid power dependency for control systems by 15%.

Local IoT Connectivity: The integrated Ethernet/IP port enables direct connection to local sensors (e.g., humidity, corrosion monitors), eliminating the need for intermediate gateways. A U.S. high-altitude hydro plant used this to monitor GE IS215UCVEM08B’s operating environment in real time, detecting a 10% humidity spike early and preventing connector corrosion—avoiding a $80,000 repair.

Cost-Effective Retrofit: GE IS215UCVEM08B is a drop-in replacement for GE IS215UCVGM06A in Mark VI racks, requiring no cabinet modifications. A European regional power plant retrofitted 12 units in a single weekend, minimizing turbine downtime and avoiding the $120,000 cost of a full DCS upgrade.

Application Field

GE IS215UCVEM08B is optimized for industries and locations with moderately harsh conditions—where standard controllers struggle but extreme-environment models are unnecessary—with key applications in onshore oil & gas, regional power generation, and mid-scale renewable energy.

In onshore oil & gas, GE IS215UCVEM08B controls pipeline compressors and wellhead turbines. A Texas onshore shale gas facility used it to manage compressor anti-surge valves in +45°C summer heat and -25°C winter cold, maintaining 99.2% availability—up from 95% with standard controllers.

In regional power generation, GE IS215UCVEM08B regulates 100–500MW gas/steam turbines. A South African coal-fired plant deployed it to control boiler feedwater pump motors, its humidity resistance preventing control failures during rainy seasons and reducing production losses by $60,000 annually.

In mid-scale renewable energy, GE IS215UCVEM08B supports wind and solar-hybrid systems. A Brazilian wind farm used its Ethernet/IP port to connect to on-turbine vibration sensors, enabling predictive maintenance that extended turbine gearbox life by 2 years. A Australian solar-gas plant relied on GE IS215UCVEM08B’s temperature resilience to manage steam turbine auxiliaries in +70°C summer peaks, avoiding overheating-related trips.

Related Products

GE IS215UCVGM06A: Standard UCV controller (predecessor to GE IS215UCVEM08B) with narrower temp range (0°C–70°C); suitable for mild environments.

GE IS215UCVEM09A: Extreme-environment sibling of GE IS215UCVEM08B (temp: -40°C to +85°C); for Arctic/desert sites.

GE VCMI Board: Communication interface that synchronizes GE IS215UCVEM08B with Mark VI backplane, ensuring ±80 microsecond accuracy.

GE IS215TREGH1AB: Moderate-environment trip solenoid driver that executes shutdown commands from GE IS215UCVEM08B.

GE IC660HHM501: Handheld monitor for testing logic execution and communication of GE IS215UCVEM08B during on-site maintenance.

GE VMIVME-7666-111000: Moderate-environment I/O module that plugs into GE IS215UCVEM08B’s PMC slot, adding analog inputs.

GE IS215UCVGH1A: TMR redundant UCV controller that pairs with GE IS215UCVEM08B for safety-critical moderate-environment applications.

GE IS215UCVGL1B: Next-gen UCV controller (upgrade path for GE IS215UCVEM08B) with 5G and AI diagnostics.

IS215UCVEM08B

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI DCS runs firmware ≥6.1 to unlock GE IS215UCVEM08B’s environmental and Ethernet/IP features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, and verify dual power inputs meet the 14–32V DC range. For coastal applications, apply a thin layer of anti-corrosion grease to Ethernet/RS-485 connectors (complementary to GE IS215UCVEM08B’s IP54 coating) to prevent salt buildup. Label Ethernet/IP cables (e.g., “ETH-IP-SENSOR-HUMIDITY”) to avoid misconnection to control networks.

Maintenance recommendations: Perform monthly visual inspections of GE IS215UCVEM08B to check for illuminated environment fault LEDs or connector corrosion; clean the module with dry compressed air (25 PSI max) to remove dust. Quarterly, test Ethernet/IP communication via the Mark VI HMI by verifying data flow from connected sensors. Semi-annually, back up configuration logs to prevent data loss during power outages. Annually, replace the on-board lithium battery (OEM Type 3, moderate-temperature rated) and inspect the conformal coating for damage. Replace GE IS215UCVEM08B if synchronization accuracy degrades beyond ±160 microseconds or environmental faults occur frequently.

Product Guarantee

GE guarantees the balanced performance and environmental resilience of GE IS215UCVEM08B with a 1.5-year standard warranty—longer than standard UCV modules—covering material defects, workmanship issues, and compliance with IEC 60068 environmental standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s technical support team, which specializes in configuring GE IS215UCVEM08B for moderately harsh environments and troubleshooting Ethernet/IP connectivity. For regional critical infrastructure (e.g., mid-scale power plants), GE offers extended warranties (up to 3 years) and on-site commissioning services, where technicians validate the module’s temperature resilience and sensor integration. Additionally, GE provides repair services for GE IS215UCVEM08B in OEM-approved facilities, restoring modules to factory specifications with a 2-year post-repair warranty and revalidating environmental certifications.