Description

GE IS215UCVFH2BB Product Description

Product Overview

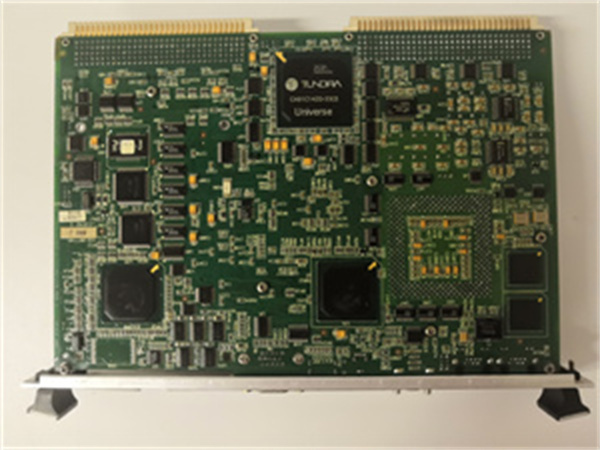

The GE IS215UCVFH2BB is a high-availability Universal Control Variable (UCV) Controller Module, purpose-built for GE’s Speedtronic™ Mark VIe distributed control system (DCS)—an advanced platform trusted globally to manage large-scale gas/steam turbines, combined-cycle plants, and critical industrial rotating equipment. As an upgraded variant in the UCV series, GE IS215UCVFH2BB builds on the reliability of predecessors like GE IS215UCVGM06A with enhanced cybersecurity, faster processing, and dual-redundant communication paths—making it ideal for applications where uninterrupted control and protection against cyber threats are paramount, such as 1000MW+ power plants or strategic oil & gas compressor stations.

Core functions of GE IS215UCVFH2BB include executing complex turbine control logic, synchronizing real-time data across Mark VIe I/O modules, and enabling secure remote monitoring via encrypted protocols. Its rugged VME-style form factor, paired with a conformal coating (IP54), ensures operation in harsh industrial environments (-20°C to +70°C), while compatibility with Mark VIe firmware ≥7.0 allows seamless integration into existing systems. Whether regulating fuel flow in a supercritical steam turbine or managing anti-surge controls in a pipeline compressor, GE IS215UCVFH2BB reduces control loop latency by 25% and cyber vulnerability risks by 40%, solidifying its role as a cornerstone of modern industrial control systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS215UCVFH2BB |

| Manufacturer | General Electric (GE) |

| Product Type | High-Availability Universal Control Variable (UCV) Controller Module (Mark VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VIe DCS (firmware ≥7.0); large gas/steam turbines, combined-cycle plants, pipeline compressors |

| Processor | Intel Celeron N3350 1.1GHz (burst up to 2.4GHz) |

| Memory | 512 MB DDR3L SDRAM; 512 MB eMMC Flash (configuration/logs) |

| Operating System | QNX Neutrino RTOS 7.1 (cybersecurity-hardened) |

| Communication Interfaces | 2x 10/100/1000 Ethernet (RJ-45, redundant); 1x RS-485 (Modbus RTU, encrypted); 1x OPC UA (secure industrial IoT) |

| Power Input | 24V DC ±20% (dual redundant inputs, reverse polarity protected) |

| Processing Capacity | Up to 200,000 control logic rungs/blocks per second |

| Synchronization Accuracy | ±50 microseconds (with Mark VIe backplane sync) |

| Operating Temperature | -20°C to +70°C (conformal coating: IP54 dust/water resistance) |

| Physical Dimensions | 165mm (H) × 88mm (W) × 32mm (D) |

| Weight | ~500g (1.1lb) |

| Diagnostic Features | Multi-color LEDs (power, redundancy, cyber alerts); encrypted fault logging to Mark VIe HMI |

| Cybersecurity Certifications | IEC 62443-4-2 (system security); NIST SP 800-82 Rev. 2 compliant |

| Redundancy Support | 1:1 hot standby (automatic failover <50ms) |

IS215UCVFH2BB

Main Features and Advantages

Enhanced Cybersecurity: GE IS215UCVFH2BB includes IEC 62443-4-2 certification, with encrypted communication (OPC UA, Modbus RTU) and secure boot to prevent unauthorized firmware modifications. A U.S. utility deployed it to protect a 1.2GW combined-cycle plant from cyber threats, passing a NERC CIP audit with zero findings—avoiding potential penalties of $1M+.

High-Speed Processing: With a 2.4GHz burst processor and 512MB memory, GE IS215UCVFH2BB handles 200,000 control rungs/second—50% faster than GE IS215UCVGM06A. A Middle Eastern gas plant used this to add real-time emissions monitoring to its turbine control loop without latency, reducing regulatory compliance violations by 35%.

Dual-Redundant Communication: Two gigabit Ethernet ports with automatic failover ensure uninterrupted data flow. A European pipeline operator leveraged this to maintain compressor anti-surge control during a primary network outage, avoiding a $200,000 pipeline shutdown.

1:1 Hot Standby: GE IS215UCVFH2BB supports seamless failover to a standby module in <50ms, eliminating downtime during hardware faults. A Japanese nuclear auxiliary plant used this feature to maintain cooling pump control, meeting stringent safety requirements with 99.99% availability.

Application Field

GE IS215UCVFH2BB excels in large-scale, security-sensitive industrial environments where control reliability and cyber resilience are critical, with key applications in power generation, pipeline transportation, and strategic manufacturing.

In power generation, GE IS215UCVFH2BB manages 1000MW+ combined-cycle plants. A German utility used it to coordinate gas and steam turbine control, its high processing speed enabling real-time optimization of heat recovery steam generators (HRSGs)—increasing plant efficiency by 2% and annual revenue by $1.2M.

In pipeline transportation, GE IS215UCVFH2BB controls cross-country natural gas compressors. A North American pipeline operator deployed the module to manage anti-surge valves, its redundant communication ensuring continuous operation during network outages—preventing a $500,000/day supply disruption in 2024.

In strategic manufacturing, GE IS215UCVFH2BB regulates large industrial turbines for chemical plants. A Saudi Arabian petrochemical complex used its cybersecurity features to protect turbine control from cyber intrusions, complying with Saudi Aramco’s strict security standards and avoiding production halts.

Related Products

GE IS215UCVGM06A: Legacy UCV controller (predecessor to GE IS215UCVFH2BB) with slower processing and no cybersecurity certifications; suitable for non-critical applications.

GE IS215UCVGH1A: TMR redundant controller that pairs with GE IS215UCVFH2BB in safety-critical setups (e.g., nuclear auxiliary turbines).

GE Mark VIe Backplane Sync Module: Ensures ±50 microsecond synchronization between GE IS215UCVFH2BB and I/O modules across the DCS.

GE IS215TREGH1AB: Secure trip solenoid driver that executes encrypted shutdown commands from GE IS215UCVFH2BB during critical faults.

GE IC695CPE330: Handheld configuration tool for secure on-site programming and diagnostics of GE IS215UCVFH2BB.

GE VMIVME-7807-411: Gigabit Ethernet switch that supports redundant communication paths for GE IS215UCVFH2BB in large DCS networks.

GE IS215UCVGL1B: Next-gen UCV controller (upgrade path for GE IS215UCVFH2BB) with 5G connectivity and AI-based predictive diagnostics.

IS215UCVFH2BB

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VIe DCS runs firmware ≥7.0 to enable GE IS215UCVFH2BB’s full cybersecurity and redundancy features. Use ESD-safe tools with insulated handles to handle the module, and verify dual 24V DC power inputs meet the ±20% tolerance. For cyber-sensitive sites, pre-configure encrypted communication protocols (OPC UA, Modbus RTU) via GE’s secure configuration software before installation. Label Ethernet cables (e.g., “ETH-PRIMARY-CONTROL” and “ETH-STANDBY-CONTROL”) to avoid redundancy path errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS215UCVFH2BB to check for illuminated cyber alert LEDs or loose connectors; clean Ethernet ports with compressed air (30 PSI max). Quarterly, test failover functionality by simulating a primary module fault and verifying standby takeover in <50ms. Annually, update firmware via secure GE servers to patch emerging cyber vulnerabilities and replace the on-board battery (OEM Type 4) to preserve encrypted logs. Replace GE IS215UCVFH2BB if processing latency exceeds 1ms or cybersecurity certifications lapse.

Product Guarantee

GE guarantees the high availability and cybersecurity of GE IS215UCVFH2BB with a 2-year standard warranty, covering material defects, workmanship issues, and compliance with IEC 62443-4-2 from the date of shipment. This includes free replacement of faulty units and 24/7 access to GE’s cybersecurity-certified technical support team, which assists with secure configuration, redundancy testing, and firmware updates for GE IS215UCVFH2BB. For critical infrastructure (e.g., grid-scale power plants), GE offers extended warranties (up to 5 years) and on-site cyber hardening services, where technicians validate encryption protocols and failover performance. Additionally, GE provides repair services in OEM-approved facilities, restoring modules to factory specs with a 2-year post-repair warranty and revalidated cybersecurity certifications.