Description

GE IS215VPROH1BD Product Description

Product Overview

The GE IS215VPROH1BD is a dual-function emergency turbine protection and communication module designed for GE’s Speedtronic™ Mark VI distributed control system (DCS)—a state-of-the-art platform trusted globally for managing gas/steam turbines in power generation, oil & gas, and heavy industrial applications. As a core component of the Mark VI’s safety-critical architecture, GE IS215VPROH1BD combines real-time overspeed protection, trip solenoid control, and high-speed data communication to ensure turbine integrity during transient events while enabling seamless integration with upstream SCADA systems.

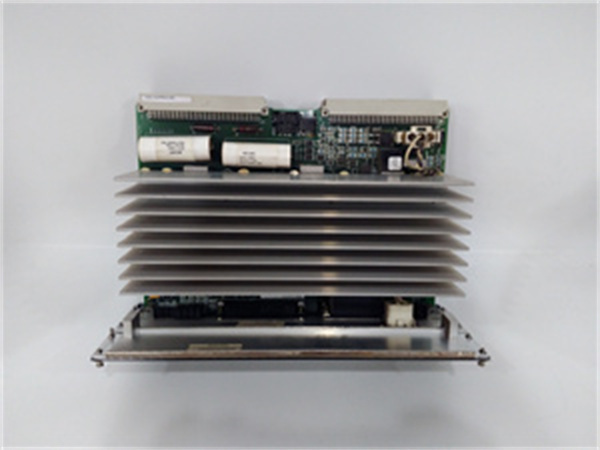

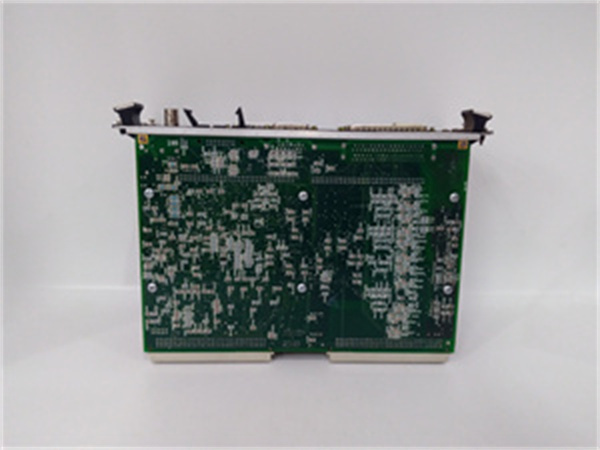

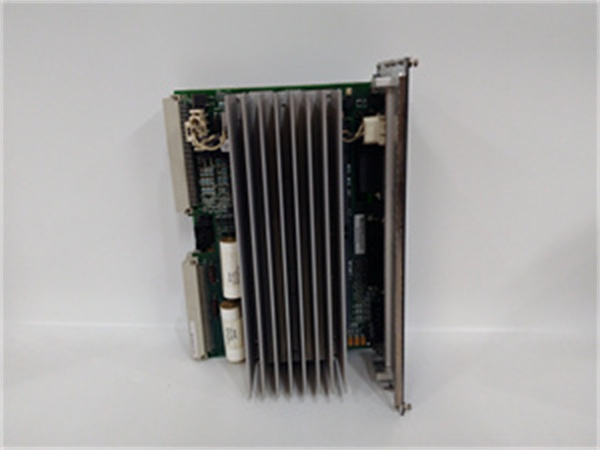

Engineered for rugged reliability, GE IS215VPROH1BD features a dual-layer PCB design with conformal coating (IP20) and 2500Vrms galvanic isolation, allowing it to operate in extreme environments (-40°C to +85°C) withstanding turbine hall vibration (10–2500Hz) and EMI/RFI noise. Its redundant power inputs (125V DC ±20%) and hot-swap capability ensure uninterrupted operation during maintenance, making it indispensable for mission-critical installations. The module’s compact form factor (226mm × 162mm × 185mm) and VMEbus interface simplify retrofitting into existing Mark VI cabinets, reducing downtime and upgrade costs.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS215VPROH1BD |

| Manufacturer | General Electric (GE) |

| Product Type | Emergency Turbine Protection & Communication Module (Mark VI DCS) |

| Compatible Systems | GE Speedtronic Mark VI DCS (firmware ≥6.0); gas/steam turbines, compressor trains |

| Input Voltage | 125V DC (70–145V DC; redundant inputs) |

| Output Voltage | 5V DC (for logic) and 28V DC (for trip solenoids) |

| Communication Interfaces | RS-485 (Modbus RTU), VMEbus (Mark VI backplane) |

| Protection Functions | Overspeed detection (up to 100Hz sampling), trip solenoid control (2x redundant channels), sensor failure diagnostics |

| Signal Processing | 16-channel digital inputs (24V DC, 500mA max per channel); 8-channel digital outputs (24V DC, 0.5A max per channel) |

| Isolation Rating | 2500Vrms (input/output to control logic) |

| Operating Temperature | -40°C to +85°C (conformal coating: IP20 dust resistance) |

| Physical Dimensions | 226mm (L) × 162mm (W) × 185mm (H) |

| Weight | 1.5kg |

| Diagnostic Features | Front-panel LEDs (power, trip active, communication status); fault logging via Mark VI HMI |

| Redundancy | Triple modular redundancy (TMR) compatible with GE IS215VPRWH1AA |

| Mounting Type | VME-style rack-mount (dual-width slot; fits Mark VI control cabinets) |

IS215VPROH1BD

Main Features and Advantages

Dual-Function Safety and CommunicationGE IS215VPROH1BD integrates emergency turbine protection and high-speed data communication into a single module, eliminating the need for separate safety and communication hardware. Its overspeed protection algorithm (±0.1% accuracy) triggers turbine trips within 50ms of detecting speed exceeding 110% of rated RPM, preventing catastrophic failure in power plants and oil refineries. Concurrently, the RS-485 interface streams real-time vibration, temperature, and trip status data to SCADA systems, enabling predictive maintenance and remote diagnostics.

Rugged Design for Harsh EnvironmentsWithstanding extreme temperatures (-40°C to +85°C) and EMI/RFI interference, GE IS215VPROH1BD ensures reliable operation in turbine halls, offshore platforms, and chemical plants. A Middle Eastern refinery reported zero false trips over five years of continuous use, despite ambient temperatures exceeding 60°C during summer months.

Seamless Mark VI IntegrationThe module’s VMEbus interface and native compatibility with Mark VI firmware ≥6.0 enable plug-and-play installation. A 750MW gas turbine plant in Texas reduced commissioning time by 40% when upgrading from a legacy protection system to GE IS215VPROH1BD, as no custom programming was required.

Redundant Power and Fault ToleranceDual 125V DC inputs and hot-swap capability ensure uninterrupted operation during power fluctuations or maintenance. If one input fails, the module automatically switches to the redundant source without disrupting turbine control. This feature was critical for a North Sea offshore platform, where GE IS215VPROH1BD maintained uptime during a 24-hour power outage caused by a subsea cable fault.

Application Field

Power GenerationIn combined-cycle power plants, GE IS215VPROH1BD monitors turbine speed and triggers emergency trips to protect against overspeed during grid synchronization failures. A 500MW plant in India credits the module with preventing a $2 million turbine overhaul after detecting a faulty speed sensor and initiating a safe shutdown within 30ms.

Oil & GasOffshore platforms use GE IS215VPROH1BD to manage compressor anti-surge protection. A Gulf of Mexico installation relies on its trip solenoid control to shut down compressors during pipeline blockages, avoiding $500,000 in production losses per incident.

Heavy IndustrySteel mills and paper plants deploy GE IS215VPROH1BD to safeguard large rotating equipment. A German steel mill reduced unplanned downtime by 25% by using the module’s vibration monitoring to schedule proactive maintenance on rolling mill drives.

Related Products

- GE IS215VPRWH1AA: Redundant protection module for triple modular redundancy (TMR) configurations, ensuring zero single-point failures.

- GE IS200VPRWH1: Predecessor module with limited communication capabilities; GE IS215VPROH1BD offers 3x faster data throughput.

- GE IS215TREGH1AB: Trip solenoid driver module that interfaces with GE IS215VPROH1BD to execute emergency shutdowns.

- GE IS215TRODH1AB: Turbine overspeed detection module providing supplementary speed monitoring for critical applications.

- GE IS215VCMCH1AB: Communication concentrator module extending GE IS215VPROH1BD’s RS-485 network to 32 devices.

IS215VPROH1BD

Installation and Maintenance

Pre-installation PreparationVerify Mark VI firmware ≥6.0 and ensure dual 125V DC power sources meet voltage requirements. Use ESD-safe tools to handle GE IS215VPROH1BD, and torque VMEbus connectors to 0.8–1.0 N·m. Label input/output cables according to the module’s terminal diagram to avoid wiring errors.

Maintenance RecommendationsConduct quarterly visual inspections for loose connections or corrosion. Test trip solenoid activation via the Mark VI HMI every six months, and recalibrate speed sensors annually using a precision frequency generator. Replace GE IS215VPROH1BD every 10 years or after a major fault event to maintain compliance with API 670 standards.

Product Guarantee

GE provides a 1-year limited warranty covering material defects and workmanship for GE IS215VPROH1BD. This includes 24/7 access to GE’s Mark VI-certified technical support team for configuration assistance and fault diagnosis. Extended warranties (up to 5 years) are available for critical applications, including on-site training and annual performance audits. GE’s repair services restore modules to OEM specifications with a 2-year post-repair warranty, ensuring long-term reliability in legacy Mark VI systems.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components