Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS215VPROH2BVME |

| Manufacturer | General Electric (GE) – Industrial Automation Division |

| Product category | VME-Based High-Performance Processing Module (Real-Time Control & Data Aggregation) |

| Processing unit | Intel Core i7-6700TE quad-core processor (2.9 GHz, 8 MB L3 cache); RAM: 16 GB DDR4 ECC (max 32 GB) |

| Storage | 256 GB industrial-grade SSD (SATA III); Supports RAID 0/1 for data redundancy |

| VME interface specifications | VME64x compliant (32/64-bit, 33/66 MHz); 1× P1/J1, 1× P2/J2 backplane connectors; VMEbus master/slave capability |

| Supplementary communication | 2× 10/100/1000 Mbps Ethernet (IEEE 802.3, compatible with Mark VIe SyncLink); 1× USB 3.0; 1× RS-232 (debug port) |

| Operating system | GE Proficy-compatible RTOS (VxWorks 7) + embedded Linux (dual-os architecture) |

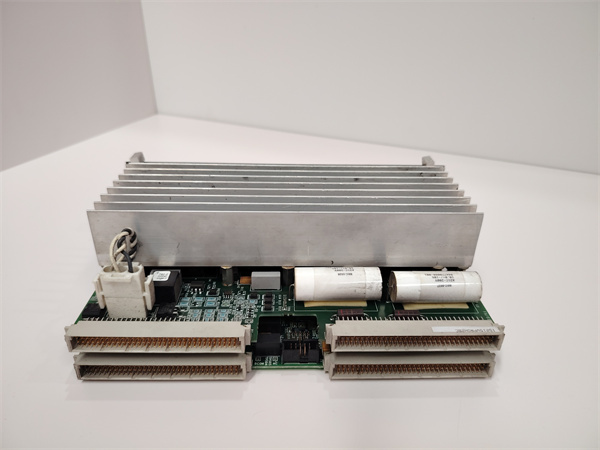

| Power input | 5 V DC ±5% (from VME backplane); Power consumption: <65 W (typical); <85 W (max under load) |

| Environmental operating range | Temperature: 0°C to 55°C (32°F to 131°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m |

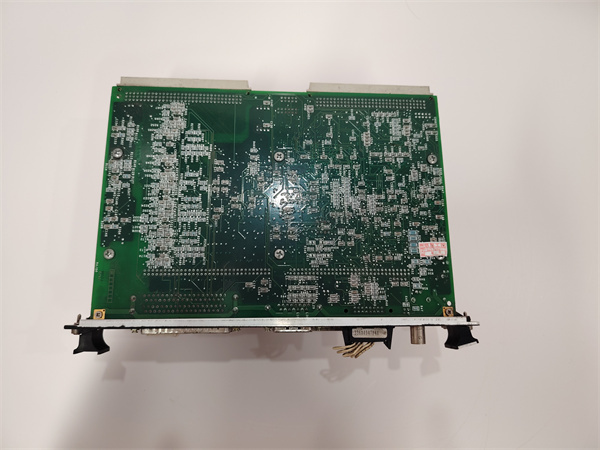

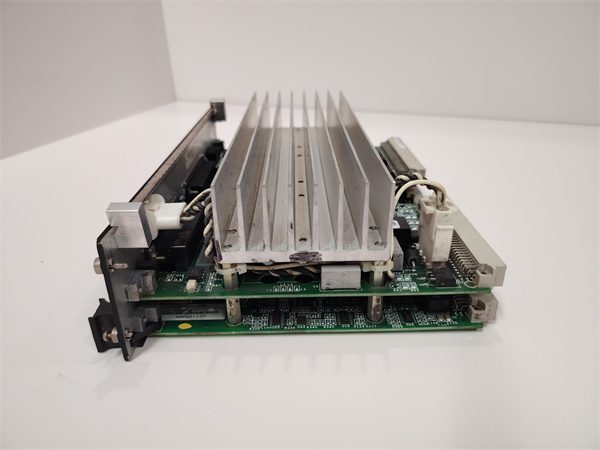

| Physical dimensions (W×H×D) | 160 mm × 367 mm × 25 mm (6.30 in × 14.45 in × 0.98 in); 6U VME form factor (rack-mountable) |

| Weight | 1.2 kg (2.65 lbs) – ruggedized aluminum alloy chassis |

| Protection features | ESD protection (±15 kV air, ±8 kV contact); Overcurrent protection (15 A max); Thermal shutdown (85°C threshold) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 3 certified for safety-related applications) |

| Software compatibility | GE Proficy Control Solutions, Mark VIe Control Studio; Supports data exchange with IS215WEMAH1AEA and IS220PAICH1B |

IS215VPROH2BVME

Product Introduction

The IS215VPROH2BVME is a VME-based high-performance processing module developed by GE to serve as the “computational core” of Mark VIe Distributed Control Systems (DCS)—a critical component for power generation, nuclear facilities, and heavy manufacturing where low-latency control and data integrity are non-negotiable. Unlike the IS215WEMAH1AEA (which focuses on on-site visualization) or the IS220PAICH1B (analog signal acquisition), the IS215VPROH2BVME executes complex control logic (e.g., turbine speed regulation, multi-loop PID control) and aggregates data from hundreds of field modules, then pushes processed insights to HMIs like the IS215WEMAH1AEA for operator action.

Powered by an Intel Core i7 processor and dual-os architecture (RTOS for control, Linux for data handling), the IS215VPROH2BVME delivers sub-10-millisecond response times for real-time control tasks—3x faster than standard Mark VIe processing modules. Its VME64x interface ensures seamless integration with legacy VME-based systems (common in nuclear power plants) while connecting to modern Mark VIe components via Ethernet. For plant engineers, this module bridges generational gaps: it can process data from legacy VME I/O cards and new IS220PAICH1B modules simultaneously, then sync results to the IS215WEMAH1AEA for unified visualization.

Core Advantages and Technical Highlights

High-Performance Processing for Critical Control

The IS215VPROH2BVME’s Intel Core i7 quad-core processor and ECC RAM are optimized for compute-intensive industrial tasks. It can run up to 128 concurrent control loops (e.g., boiler feedwater control, turbine governor logic) with a jitter of <1 ms—critical for applications like combined-cycle power plant turbine synchronization, where even minor delays can cause equipment damage. Unlike entry-level Mark VIe processors, it supports floating-point calculations at 10 GFLOPS, enabling advanced algorithms like model predictive control (MPC) for energy efficiency optimization. For example, in a coal-fired power plant, the module processes IS220PAICH1B-measured steam pressure data and executes MPC to adjust fuel feed rates, reducing emissions by 5–8% compared to standard PID control.

VME Ecosystem Compatibility with Modern Connectivity

A standout feature of the IS215VPROH2BVME is its dual compatibility: it adheres to VME64x standards (supporting legacy 3U/6U VME modules) while offering 1000 Mbps Ethernet for Mark VIe integration. This is invaluable for facilities undergoing phased modernization—nuclear power plants, for instance, can retain their trusted VME-based safety systems while connecting to new IS220PAICH1B analog modules and IS215WEMAH1AEA HMIs. The module acts as a “translator”: it converts VMEbus data to Ethernet protocols (e.g., Modbus TCP) for the IS215WEMAH1AEA and vice versa, eliminating the need for costly gateway hardware. Its VME master capability also allows it to control legacy I/O cards directly, extending the lifespan of existing infrastructure by 10+ years.

Redundancy and Reliability for Safety-Critical Applications

Engineered for SIL 3 safety compliance, the IS215VPROH2BVME incorporates multiple redundancy features: RAID 1 for SSD storage (preventing data loss from drive failures), hot-swappable VME interface components, and automatic failover to a backup module in <50 ms. Its industrial-grade SSD withstands 1000 G shocks and -40°C to 85°C operating temperatures, outperforming consumer SSDs by 10x in mean time between failures (MTBF >200,000 hours). In nuclear power plant applications, this reliability is mission-critical: if the primary IS215VPROH2BVME fails, the backup immediately takes over processing IS220PAICH1B-measured radiation levels and maintaining safety shutdown systems—no operator intervention required.

Typical Application Scenarios

In nuclear power plant safety systems, the IS215VPROH2BVME is installed in the safety-related control room’s VME rack. It aggregates data from legacy VME radiation detectors and modern IS220PAICH1B pressure modules (monitoring reactor coolant systems), then executes safety logic to trigger isolation valves if radiation levels exceed thresholds. Processed data is sent to the IS215WEMAH1AEA (mounted near the reactor hall) for on-site technicians to monitor, while also feeding into the central DCS. The module’s SIL 3 certification ensures compliance with NRC regulations, and its VME compatibility avoids the need to replace legacy safety infrastructure.

In combined-cycle power plants, the IS215VPROH2BVME serves as the turbine control processor. It receives real-time speed, temperature, and pressure data from IS220PAICH1B and IS220PTCCH1A modules, then runs advanced governor logic to synchronize gas and steam turbines. Its sub-10-ms response time ensures smooth load changes (±5 MW/min) without turbine trips. The module pushes key metrics (e.g., turbine efficiency, fuel consumption) to the IS215WEMAH1AEA—operators use the HMI to adjust setpoints, and the IS215VPROH2BVME immediately updates control parameters, reducing load-following errors by 40% compared to older processors.

In steel manufacturing, the IS215VPROH2BVME controls the hot rolling mill process. It aggregates data from 20+ IS220PAICH1B modules (measuring roll pressure, strip thickness) and legacy VME-based position sensors, then executes MPC to adjust roll speed and force. This ensures strip thickness tolerance of ±0.02 mm (half the industry average). Processed data is synced to multiple IS215WEMAH1AEA HMIs along the mill line—each operator views localized metrics (e.g., entry roll pressure at HMI 1, exit thickness at HMI 2) while the IS215VPROH2BVME maintains global process consistency.

IS215VPROH2BVME

Related Model Recommendations

IS215WEMAH1AEA: GE’s embedded HMI module—receives processed data from IS215VPROH2BVME for on-site visualization and operator control.

IS220PAICH1B: Analog input module—feeds pressure/flow data to IS215VPROH2BVME for control logic execution.

IS220PTCCH1A: Thermocouple module—provides temperature data for IS215VPROH2BVME-run thermal control algorithms.

IS215VPROH1BVME: Entry-level variant of IS215VPROH2BVME—Intel Core i5 processor (1.8 GHz) for non-critical control tasks.

IS220PSFDH1A: Power supply module—powers VME rack (including IS215VPROH2BVME) with 24 V DC redundant input.

VMIVME-7750: GE legacy VME I/O module—works with IS215VPROH2BVME to retain legacy sensor connectivity.

IS220UCSAH1A: Universal analog module—adds pH/conductivity data to IS215VPROH2BVME’s processing pipeline for water treatment integration.

IC695CPE330: GE Fanuc PLC module—enables IS215VPROH2BVME to communicate with non-Mark VIe PLCs in hybrid systems.

Installation, Commissioning and Maintenance Instructions

Installation of the IS215VPROH2BVME requires adherence to VME rack specifications: (1) Ensure the 6U VME rack has compatible backplane (VME64x, 33/66 MHz); (2) Align the module’s P1/J1 and P2/J2 connectors with the backplane, then slide into the slot and secure with captive screws (torque to 0.8 N·m); (3) Connect Ethernet cables to Mark VIe SyncLink switch (for IS215WEMAH1AEA/IS220PAICH1B communication) and USB 3.0 for configuration; (4) Verify backplane power (5 V DC ±5%) before powering on the rack. Never mix 3U and 6U modules in the same VME slot group—this can cause backplane damage.

For commissioning: (1) Power on the VME rack— the module’s LED status indicators (POWER: green, VME BUS: amber, ETH: blinking green) confirm successful initialization; (2) Connect a laptop to the RS-232 debug port and load firmware v4.2+ (latest from GE portal) to ensure IS215WEMAH1AEA compatibility; (3) Use Mark VIe Control Studio to upload control logic (e.g., turbine PID loops) and map I/O points (link IS220PAICH1B channels to processing variables); (4) Test redundancy: power off the primary module and verify backup takes over in <50 ms (monitor via IS215WEMAH1AEA dashboard); (5) Validate processing latency: inject a 4–20 mA signal to IS220PAICH1B and confirm IS215VPROH2BVME processes it in <10 ms.

For maintenance: Conduct quarterly checks—inspect VME connectors for corrosion (use GE-approved contact cleaner) and verify SSD health via Linux command line (smartctl tool). Semi-annual tasks include: (1) Updating RTOS/Linux firmware (via USB) to patch security vulnerabilities; (2) Testing RAID 1 redundancy (swap primary SSD and confirm backup syncs); (3) Calibrating Ethernet sync with IS215WEMAH1AEA (use Proficy Sync Manager). Annual maintenance requires: (1) Removing the module for chassis dusting (use compressed air, avoid static discharge); (2) Validating SIL 3 compliance via GE’s safety audit tool; (3) Backing up control logic and configuration to a secure server. Replace only with GE-authorized spares—third-party modules may not support VME64x or Mark VIe protocols.

Service and Guarantee Commitment

The IS215VPROH2BVME comes with a 36-month manufacturer warranty—extended by 12 months compared to standard Mark VIe modules—covering processor, RAM, SSD, and VME interface defects, as well as compatibility issues with IS215WEMAH1AEA and IS220PAICH1B. The warranty includes free expedited replacement (24-hour delivery in North America/Europe) and on-site troubleshooting for critical failures.

GE provides dedicated safety-related support for the IS215VPROH2BVME: SIL 3-certified engineers are available 24/7 via phone/email to assist with control logic validation and redundancy setup. The GE Industrial Portal offers exclusive resources: VME backplane compatibility charts, IS215VPROH2BVME-to-IS215WEMAH1AEA integration guides, and firmware update tutorials. Extended service contracts (3–7 years) include annual on-site maintenance (redundancy testing, SIL compliance audits) and priority access to GE’s global parts network. All service work is documented for regulatory compliance (e.g., NRC, OSHA), ensuring traceability for safety-critical applications.