Description

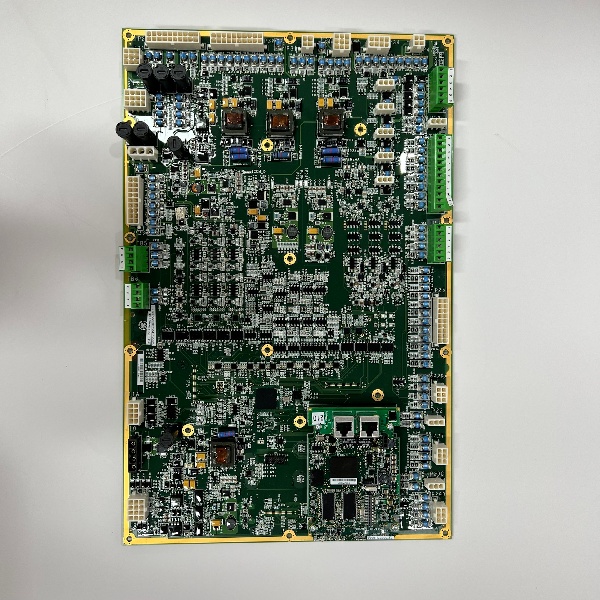

GE IS215WETAH1BB Mark V Analog I/O Board

Product Overview

The IS215WETAH1BB is a high-precision analog I/O board developed by GE, specifically designed for the classic Mark V gas turbine control system. As a core signal processing component in turbine automation, this board serves as the “signal hub” between field sensors/actuators and the main control unit, responsible for scaling, conditioning, and transmitting a wide range of analog and discrete signals critical to turbine operation .

What distinguishes the IS215WETAH1BB is its versatile signal handling capability. Unlike specialized I/O modules that only process single-type signals, it integrates processing for LVDT position inputs, servo valve outputs, thermocouple temperature readings, 4-20 mA process signals, and vibration data—all within a single board. This integration simplifies the Mark V system architecture, reduces wiring complexity, and ensures consistent signal synchronization, making it an indispensable component for legacy and retrofit gas turbine installations in power generation and industrial sectors.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS215WETAH1BB |

| Manufacturer | GE (General Electric) |

| Product Type | Analog I/O Processing Board |

| Compatible System | GE Mark V Gas Turbine Control System |

| Signal Handling | LVDT/LVDR inputs, thermocouple inputs, 4-20 mA I/O, ±10 VDC inputs, vibration inputs, servo valve outputs, relay drives, pulse inputs |

| Output Current Range | Configurable via jumpers: 4-20 mA or 4-200 mA |

| Key Connectors | 3PL (data bus), JE (generator/line signals), JF (LVDT inputs), JG (vibration/voltage inputs) |

| Configuration | Hardware jumpers (J1/J2: output circuit selection; J5/J6: current range; J7: RS232 test; J8: oscillator) |

| Operating Temperature | 0°C to +60°C (32°F to +140°F) |

| Power Supply | Derived from Mark V TCPS power board via 2PL connector |

| Physical Dimensions | Standard Mark V board form factor (~165 mm × 100 mm × 25 mm) |

| Mounting | I/O Core R1/R2/R3 of Mark V system |

| Origin | United States |

IS215WETAH1BB

Main Features and Advantages

Versatile Multi-Signal Processing

The IS215WETAH1BB eliminates the need for multiple dedicated modules by handling diverse signal types. It processes LVDT signals from fuel valve position sensors, thermocouple data from turbine exhaust temperature monitors, 4-20 mA signals from compressor pressure transducers, and vibration inputs from bearing sensors—all in real time . For a 150 MW gas turbine, this means over 20 critical operating parameters are managed through one board, reducing system footprint and potential failure points.

Precision Signal Conditioning

Equipped with advanced analog circuitry, the board ensures high-accuracy signal processing. It provides cold-end compensation for thermocouple inputs (critical for temperature measurement accuracy) and linearization for LVDT position signals, minimizing measurement errors to ±0.1% of full scale. This precision is vital for controlling fuel flow via servo valves, where even small signal deviations could lead to inefficient combustion or turbine instability.

Flexible Configuration

Hardware jumpers enable on-site customization without software programming. Jumpers J5 and J6 allow technicians to switch output current ranges between 4-20 mA (for standard actuators) and 4-200 mA (for high-power valves), while J7 facilitates RS232-based board testing during maintenance . This flexibility makes the board adaptable to different turbine models and retrofit requirements, extending its utility across GE’s gas turbine product line.

Seamless System Integration

The board connects seamlessly to other Mark V components via dedicated connectors: the 3PL connector links to the STCA and TCQE boards for COREBUS data transmission, while the JE connector exchanges generator and line signals with the TCQC board . This integrated communication ensures that conditioned signals reach the main controller with minimal latency, enabling rapid control responses to load changes or process disturbances.

Application Field

Combined-Cycle Power Plants

In a 500 MW combined-cycle plant, IS215WETAH1BB boards manage key signals for gas turbine operation: they process LVDT inputs from inlet guide vanes, thermocouple data from turbine stages, and 4-20 mA signals from fuel flow meters. A plant in Southeast Asia retrofitted aging I/O modules with IS215WETAH1BB, reducing signal noise in exhaust temperature measurements by 60% and enabling more precise combustion control—cutting NOx emissions by 8% while maintaining efficiency.

Petrochemical Refineries

Refineries rely on gas turbines to drive process compressors, where IS215WETAH1BB handles critical control signals. A Gulf Coast refinery uses the board to process vibration data from compressor bearings and servo valve outputs for fuel control. During a recent upset, the board’s rapid signal conditioning allowed the Mark V system to detect a compressor stall precursor (via pressure signal anomalies) and adjust fuel flow within 200 ms, avoiding a costly shutdown that could have cost $500,000 in lost production.

Industrial Cogeneration Systems

Small-to-medium gas turbine CHP systems in manufacturing facilities benefit from the board’s compact integration. A food processing plant in Europe uses IS215WETAH1BB to manage temperature (thermocouples), steam pressure (4-20 mA), and turbine speed (pulse inputs) signals. The board’s ability to consolidate these signals simplified the system’s wiring by 40%, reducing installation time and maintenance costs associated with troubleshooting discrete modules.

Related Products

TCPS Power Board: Supplies regulated power to IS215WETAH1BB via the 2PL connector, ensuring stable signal processing .

STCA Communication Board: Exchanges conditioned signals with IS215WETAH1BB via the 3PL data bus, transmitting data to the Mark V COREBUS .

TCQC Signal Interface Board: Communicates generator and line signals with IS215WETAH1BB through the JE connector .

TBQA/TBQC Terminal Boards: Provide field wiring interfaces for thermocouples (TBQA) and 4-20 mA/LVDT signals (TBQC), connecting to the board’s JA/JB/JF connectors .

IS215WETAH1C: Updated variant with enhanced noise filtering, compatible with Mark V systems in high-electromagnetic-interference environments .

GE Mark V Maintenance Software: Used with the board’s J7 RS232 test port for signal calibration and troubleshooting.

IS215WETAH1BB

Installation and Maintenance

Pre-Installation Preparation

Verify compatibility with the Mark V I/O core (R1/R2/R3) and ensure TCPS power board firmware is up to date. Inspect the board for physical damage (e.g., bent pins on connectors) and confirm jumper settings match the application: set J5/J6 to 4-20 mA for standard actuators or 4-200 mA for high-current valves . Prepare tools: anti-static wristband, torque screwdriver (0.5-0.8 N·m), and multimeter. Power off the Mark V system before installation.

Installation Steps

Align the board with guide rails in the designated I/O core slot, ensuring connector pins mate with the backplane. Push firmly until seated, then secure with front panel screws (torque to 0.6 N·m). Connect field wiring via TBQA/TBQC terminal boards to the corresponding connectors (e.g., thermocouples to JA, LVDT to JF). Verify 3PL/JE connections to STCA/TCQC boards are secure to avoid communication errors.

Maintenance Recommendations

Monthly: Perform visual inspections for loose connectors or dust accumulation; use compressed air to clean ventilation slots.

Quarterly: Use the RS232 J7 port and test software to verify signal accuracy (e.g., calibrate 4-20 mA outputs against a precision multimeter).

Annually: Recheck jumper settings and terminal block torque; inspect for corrosion on field wiring connectors (critical in humid environments).

Troubleshooting: If signals are erratic, first check terminal board wiring, then test the board via J7 before replacing—false faults often stem from loose connections rather than board failure.

Product Guarantee

GE authorizes distributors provide a 12-month warranty for new IS215WETAH1BB boards, covering manufacturing defects in components and signal processing functionality. For refurbished units (common in legacy Mark V systems), warranties typically range from 6-12 months, covering performance to OEM specifications. During the warranty period, authorized service providers offer technical support for installation, jumper configuration, and signal calibration.

Given the board’s role in legacy turbine systems, GE recommends using genuine IS215WETAH1BB modules (not third-party alternatives) to maintain system compatibility and avoid control loop instability. Extended service contracts are available, including annual on-site calibration and priority replacement for critical failures—ensuring continued reliability of Mark V systems that may have decades of remaining service life.