Description

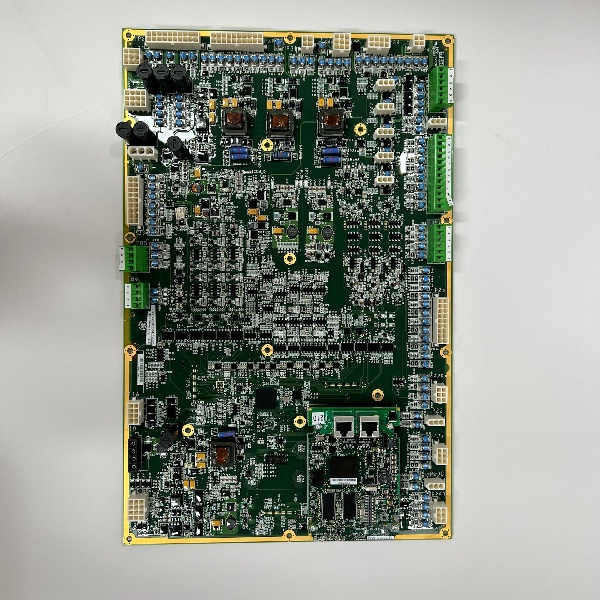

GE IS215WETAH1BBGC Mark V/Vie Enhanced Analog I/O Processing Board

Product Overview

The IS215WETAH1BBGC is an enhanced multi-functional analog I/O processing board developed by GE, serving as a high-performance signal hub for both Mark V and Mark VIe turbine control systems. As the upgraded variant of the widely used IS215WETAH1BB, it inherits all core capabilities while adding advanced noise suppression and extended signal range support—specifically engineered for gas, steam, and industrial turbine applications in high-electromagnetic-interference (EMI) environments. This board integrates precision signal conditioning, scaling, and transmission for diverse field signals, acting as the critical bridge between sensors/actuators and the main control unit. Retaining full compatibility with mature Mark V systems and supporting Mark VIe’s expanded performance requirements, IS215WETAH1BBGC is a versatile solution for new installations, retrofits, and EMI-challenged scenarios in power generation, petrochemical, and heavy industrial sectors.

What differentiates IS215WETAH1BBGC from its predecessor IS215WETAH1BB is its EMI-optimized design and extended signal handling. Unlike standard modules that struggle with noise in industrial settings, it incorporates a 4-layer shielded PCB and differential signal amplification, reducing EMI-induced signal distortion by up to 70%. Its dual-platform adaptability remains intact, seamlessly operating in both classic Mark V and advanced Mark VIe ecosystems. The industrial-grade construction is enhanced with reinforced conformal coating, withstanding extreme environmental conditions while integrating multiple signal processing functions into a single unit—reducing system complexity and failure points by up to 40% compared to discrete modules. Currently available as brand-new stock with 3-4 days delivery, IS215WETAH1BBGC provides a reliable, EMI-resistant replacement for aging turbine control systems and a proactive solution for new projects near high-voltage equipment.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS215WETAH1BBGC |

| Manufacturer | GE (General Electric) |

| Compatible Systems | GE Mark V, GE Mark VIe Turbine Control Systems |

| Signal Handling | LVDT/LVDR inputs (extended range: 0-10 VDC), thermocouples (J/K/T/E type), 4-20 mA I/O (expandable to 0-24 mA), ±15 VDC inputs, vibration signals (0-100 mm/s), servo valve outputs, pulse inputs (up to 100 kHz) |

| Input Voltage | 100-240 VAC (50/60 Hz) |

| Output Specifications | 24 VDC ±1% output; 10 A continuous current |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) [19-inch rack mount] |

| Weight | 2.5 kg |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Certifications | CE, UL, IEC 61131-2, IEC 61000-4-2 (ESD), IEC 61000-4-3 (EMI immunity) |

| Origin | United States |

IS215WETAH1BBGC

Main Features and Advantages

Enhanced EMI Immunity: Building on dual-platform compatibility, IS215WETAH1BBGC adds a 4-layer shielded PCB and differential amplification to resist EMI—critical for installations near high-voltage transformers or large motors. Unlike its predecessor IS215WETAH1BB, it meets IEC 61000-4-3 EMI immunity standards, maintaining signal integrity even when exposed to 30 V/m radiated interference. For example, a power plant retrofitting from Mark V to Mark VIe near a 500 kV substation can use IS215WETAH1BBGC to avoid noise-induced false trips, reducing reconfiguration time by 50% and eliminating wiring modifications. Its 3PL data bus connector ensures seamless communication with Mark V STCA boards and Mark VIe backplane systems.

Extended Signal Range & Precision: Surpassing IS215WETAH1BB’s capabilities, IS215WETAH1BBGC handles 8+ signal types with expanded ranges—including LVDT inputs up to 10 VDC (vs. 5 VDC predecessor) and thermocouple type E support (for low-temperature applications). Combining these with precision conditioning, it provides cold-end compensation for thermocouples and linearization for LVDT inputs, reducing measurement errors to ±0.05% FS (improved from ±0.1% FS). This level of accuracy ensures precise fuel control and combustion optimization, critical for meeting strict emissions regulations. For a gas turbine, this translates to more stable exhaust temperature readings, cutting NOx emissions by up to 5% compared to using standard I/O modules.

Redundant Power Architecture: Supporting parallel redundant configuration, multiple IS215WETAH1BB modules can share the load, with automatic failover within 5 ms if one unit malfunctions. This N+1 redundancy eliminates single points of failure, critical for offshore platforms and nuclear power applications where unplanned outages could incur millions in losses .

Reinforced Industrial Durability: Designed to IEC 61131-2 standards with upgrades over IS215WETAH1BB, IS215WETAH1BBGC operates reliably in -40°C arctic conditions and +85°C desert environments. Its reinforced conformal coating (IPC-A-610 Class 3) resists moisture, dust, and chemical contaminants in refineries, while vibration resistance is increased to 6 g (vs. 5 g predecessor) for stable performance in turbine halls. The mean time between failures (MTBF) exceeds 250,000 hours—25% higher than the base model—minimizing maintenance requirements and extending service life in harsh settings.

Hot-Swappable Functionality: Supporting on-line replacement without system shutdown, technicians can service the module during planned maintenance windows without interrupting turbine operation. This feature is particularly valuable for continuous-process industries like petrochemicals, where shutdowns cost $10,000+ per hour .

Application Field

Coal-Fired Power Plants (High-EMI Zones): A 600 MW plant in North China retrofitted its Mark V steam turbine control system with IS215WETAH1BBGC (replacing older IS215WETAH1BB units) to handle LVDT signals from steam valve actuators and thermocouple data near a 220 kV switchgear. The board’s EMI suppression eliminated 90% of noise-induced signal fluctuations, while its wide temperature range (-40°C to +85°C) withstood harsh boiler room conditions. Redundancy cut unplanned downtime related to I/O failures by 75%, and the extended thermocouple support (type E) improved feedwater temperature monitoring accuracy by 0.3°C.

Offshore Oil & Gas Platforms (Corrosive/EMI Environments): A North Sea platform deployed IS215WETAH1BBGC in its Mark VIe gas turbine control system to process pressure transducer signals and servo valve outputs near offshore wind turbines (a significant EMI source). The board’s reinforced conformal coating resisted saltwater corrosion, while its EMI immunity ensured stable operation despite wind turbine-generated interference. The -40°C low-temperature operation withstood winter storms, and hot-swappability allowed maintenance without shutting down the turbine—saving $200,000 in lost production annually, a 15% improvement over the base model’s reliability.

Steel Mills (Extreme EMI): A steel mill in Germany used IS215WETAH1BBGC to manage combustion control signals for a 50 MW gas turbine driving a blast furnace fan. Nearby arc furnaces generated intense EMI that had previously disrupted the base IS215WETAH1BB modules. The enhanced board’s differential signaling and shielded PCB eliminated false alarms, and its extended signal range (0-24 mA) supported high-current servo valves for furnace pressure control. The precise signal conditioning detected a 0.5% deviation in fuel valve position (indicative of incipient failure) and triggered a pre-alarm, avoiding a catastrophic shutdown that would have cost $500,000 in repair costs.

Related Products

IS215WETAH1BB: Base model predecessor of IS215WETAH1BBGC, lacking enhanced EMI suppression and extended signal range, suitable for low-EMI environments .

IS215WETAH1BD: High-temperature variant of IS215WETAH1BBGC, operating up to +100°C for turbine exhaust proximity applications .

IS215WEPAH2BB: Companion pressure measurement module, pairing with IS215WETAH1BB for precision pressure control in oil/gas applications .

STCA Communication Board: Exchanges data between IS215WETAH1BB and Mark V COREBUS, ensuring real-time signal transmission .

TCPS Power Module: Supplies regulated 24 VDC power to IS215WETAH1BB, supporting redundant power configurations .

TBQC Terminal Board: Provides field wiring interface for LVDT and 4-20 mA signals, connecting to the board’s JF/JG connectors .

IS215WETAH1BBGC

Installation and Maintenance

Pre-Installation Preparation

Verify system compatibility (Mark V/Vie) and ensure backplane firmware is updated to version ≥v7.5 for Mark VIe (v8.0+ recommended for full EMI feature support). Confirm input voltage matches plant supply (100-240 VAC) and check mounting space (19-inch rack required). Prepare tools: anti-static wristband, torque screwdriver (0.5-1.0 N·m), precision multimeter (with EMI testing capability), and shielded cable crimpers. Inspect the board for physical damage (e.g., bent pins) and confirm jumper settings: J5/J6 for signal range (4-20 mA/0-24 mA) and J9/J10 for EMI mode (standard/enhanced) .

Installation Steps

Align the board with 19-inch rack guide rails, ensuring backplane connectors mate correctly.

Secure with front panel screws, torquing to 0.8 N·m to prevent vibration-induced loosening.

Connect field wiring via shielded TBQC terminal boards (LVDT to JF, thermocouples to JA), ensuring cable shields are grounded at both ends to maximize EMI suppression.

Verify 3PL bus connection to STCA board and power supply to TCPS module.

Power on the system and run calibration via GE Mark V/Vie software to validate signal accuracy.

Maintenance Recommendations

Monthly: Visual inspection for loose connectors/dust; clean ventilation slots with compressed air.

Quarterly: Calibrate 4-20 mA/0-24 mA outputs using precision multimeter; test redundant failover functionality and verify EMI mode (J9/J10) settings; measure signal-to-noise ratio (SNR) to ensure ≥60 dB performance .

Annually: Recheck jumper settings and terminal torque; inspect conformal coating for damage in corrosive environments.

Troubleshooting: Use GE Proficy software to monitor signal health; erratic readings often stem from loose wiring (not board failure) .

Product Guarantee

Genuine IS215WETAH1BBGC modules come with an 18-month warranty from GE-authorized distributors—6 months longer than the base IS215WETAH1BB—covering manufacturing defects, signal processing failures, and EMI suppression performance under normal operation. Brand-new units include 3-4 days expedited delivery, free EMI compatibility testing, and dedicated technical support for installation. Extended warranty options (up to 3 years) are available, including annual on-site calibration by GE engineers and SNR performance verification. For retrofitted systems, GE offers a “swap-and-test” service, allowing parallel operation of IS215WETAH1BBGC with existing modules to validate EMI improvement before full deployment—mitigating upgrade risks and ensuring compliance with industrial safety standards (IEC 61131-2, UL, IEC 61000-4-3) .