Description

Product Overview

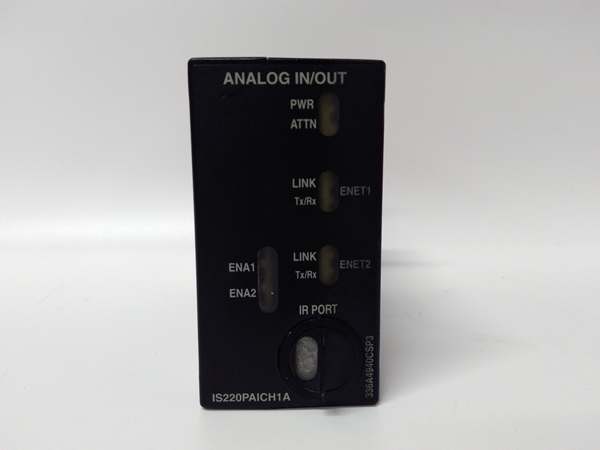

The IS220PAICH1 is a high-performance power supply module developed by GE, specifically designed for the Mark VIe turbine control system to provide stable and reliable power to critical control components. As an essential part of GE’s turbine automation ecosystem, IS220PAICH1 converts AC input power into regulated DC power, ensuring consistent operation of I/O modules, processors, and communication devices within the control system. Its robust design and redundant capabilities make IS220PAICH1 a cornerstone for maintaining uninterrupted turbine control in power generation, petrochemical, and industrial applications.

What distinguishes IS220PAICH1 is its ability to deliver clean, regulated power even in harsh industrial environments. Unlike standard power supplies, it incorporates advanced filtering to suppress voltage spikes and electromagnetic interference, protecting sensitive control electronics from damage. Whether deployed in new turbine installations or as a replacement in legacy systems, IS220PAICH1 ensures the stability of the entire control chain, directly contributing to turbine safety and operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS220PAICH1 |

| Manufacturer | GE (General Electric) |

| Product Type | Mark VIe Turbine Control Power Supply Module |

| Input Voltage | 110-240 VAC (50/60 Hz) |

| Output Voltage | 24 VDC ±0.5% |

| Output Current | 10 A (continuous); 15 A (peak for 10 seconds) |

| Efficiency | ≥90% at full load |

| Protection Features | Overvoltage, overcurrent, short-circuit, overtemperature |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| MTBF (Mean Time Between Failures) | >200,000 hours |

| Physical Dimensions | 120 mm × 160 mm × 40 mm |

| Mounting | Mark VIe rack mount (IS200RACK01A compatible) |

| Redundancy Support | N+1 redundant configuration |

| Certifications | UL 60950-1, CE, IEC 61010-1, RoHS 2.0 |

IS220PAICH1

Main Features and Advantages

Stable power regulation: IS220PAICH1 maintains a 24 VDC output with ±0.5% accuracy, even when input voltage fluctuates by ±20%—a critical feature for sensitive turbine control electronics. For example, in a gas turbine control system, this stability ensures consistent operation of speed sensors and vibration monitors, preventing false readings that could trigger unnecessary shutdowns. The module’s low output ripple (<50 mV peak-to-peak) further protects analog circuits from noise interference.

Comprehensive protection mechanisms: Equipped with multi-layer protection, IS220PAICH1 safeguards both itself and connected devices. Overvoltage protection (clamping at 27 VDC) prevents damage to 24 VDC I/O modules, while overcurrent and short-circuit protection automatically limits output current to 12 A, avoiding wire overheating. Overtemperature protection shuts down the module if internal temperatures exceed +75°C, with automatic recovery once cooled—ensuring safe operation in poorly ventilated control cabinets.

Redundancy readiness: IS220PAICH1 supports N+1 redundancy, allowing multiple modules to share the load. In a typical setup, two IS220PAICH1 units power the same control rack: if one fails, the other seamlessly takes over within 5 ms, maintaining uninterrupted power. This redundancy is vital for nuclear or offshore turbine applications, where power loss could lead to catastrophic consequences, reducing downtime risk by over 99%.

Industrial-grade durability: Built to withstand turbine hall conditions, IS220PAICH1 operates reliably in -20°C to +60°C temperatures and resists vibration up to 5 g (10-500 Hz). Its rugged casing and conformal-coated PCB protect against dust, moisture, and chemical contaminants, ensuring a long service life even in harsh environments like desert power plants or coastal refineries.

Application Field

In combined-cycle power plants, IS220PAICH1 powers the Mark VIe control system’s critical components. A 1,000 MW plant in the U.S. uses two redundant IS220PAICH1 modules to supply power to speed monitoring, vibration sensing, and fuel control modules. During a recent grid voltage surge (110% of nominal), the modules’ overvoltage protection clamped the output at 27 VDC, preventing damage to $50,000 worth of I/O equipment and avoiding a 4-hour shutdown.

In petrochemical refineries, IS220PAICH1 ensures reliable operation of steam turbine controls. A refinery in the Middle East deployed IS220PAICH1 in a hot, dusty environment: its -20°C to +60°C operating range withstood summer temperatures up to +55°C in the control cabinet, while its filtering reduced noise from nearby high-voltage motors. This stability has kept the turbine control system operational with zero power-related failures for over 2 years.

In offshore wind-gas hybrid platforms, IS220PAICH1’s redundancy feature is critical. A North Sea platform uses three IS220PAICH1 modules in N+1 configuration to power the gas turbine control system: during a recent storm, one module failed due to moisture ingress, but the remaining units took over instantly, preventing a turbine trip. The platform’s operator estimates this saved $200,000 in lost production and repair costs.

Related Products

IS220PAICH2: A higher-capacity variant of IS220PAICH1 with 15 A continuous output, designed for larger Mark VIe systems with more I/O modules.

IS200RACK01A: Mark VIe 10-slot rack that houses IS220PAICH1 and control modules, providing mechanical support and power distribution.

IS200CPUH1AAA: Mark VIe main controller powered by IS220PAICH1, relying on its stable output for precise turbine control.

IS200PWR131: Redundancy module that enables N+1 configuration with IS220PAICH1, managing load sharing and failover.

IS220PACD1A: Power distribution module compatible with IS220PAICH1, splitting 24 VDC output to multiple sub-systems.

GE Proficy Diagnostics: Software that monitors IS220PAICH1 status, alerting operators to voltage fluctuations or impending failures.

IS200FUSE001: Replacement fuse kit for IS220PAICH1, protecting the module from input overcurrent.

IS220PAICH1

Installation and Maintenance

Pre-installation preparation: Before installing IS220PAICH1, verify the input voltage (110-240 VAC) matches the plant’s supply and ensure the Mark VIe rack (e.g., IS200RACK01A) has a dedicated power slot. Check the installation environment for temperature (-20°C to +60°C) and humidity (5-95% non-condensing) compliance. Prepare tools: torque screwdriver (1.0-1.5 N·m), multimeter, and insulated gloves. Power off the system, align the module with the rack guides, insert until fully seated, and secure with front screws (torque to 1.2 N·m). Connect input wiring to the terminal block, ensuring proper grounding to reduce noise.

Maintenance recommendations: Conduct monthly visual inspections of IS220PAICH1, checking for loose connections, discolored components, or dust accumulation. Use a multimeter to verify output voltage (24 VDC ±0.5%) and ensure fans (if equipped) are functioning. Every 6 months, clean ventilation slots with compressed air and retighten terminal screws. For redundant setups, test failover functionality quarterly by temporarily disconnecting one IS220PAICH1 and confirming the other takes over. Replace with genuine GE modules if output voltage deviates beyond specs or protection features activate repeatedly.

Product Guarantee

GE provides a 36-month warranty for IS220PAICH1, covering manufacturing defects, output regulation failures, and protection circuit malfunctions under normal operation. During the warranty period, GE offers free replacement within 72 hours for critical failures, with expedited shipping for power plants and refineries. Our 24/7 technical support team provides remote guidance for installation, redundancy setup, and troubleshooting. Extended warranty options (up to 5 years) include annual on-site testing to validate output stability and protection functions. This guarantee underscores GE’s confidence in IS220PAICH1’s reliability and commitment to keeping your turbine control system powered without interruption.