Description

GE IS220PAICH1A Product Description

Description

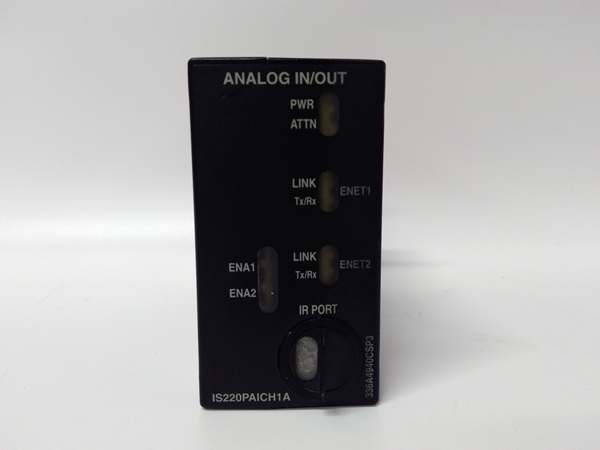

The IS220PAICH1A is a high-performance analog input/output (I/O) module engineered by General Electric (GE), serving as a core interface component of the Mark VI and Mark VIe Speedtronic turbine control systems. It integrates dual functionality: converting continuous analog signals from field sensors (e.g., temperature, pressure, flow transmitters) into digital data for controllers, and reversing the process to translate digital control commands into analog outputs for actuators like valves and pumps. This dual-role design eliminates the need for separate input and output modules, making it a compact, cost-effective solution for precision monitoring and control in harsh industrial environments.

Application Scenarios

A 350MW gas-fired power plant in Southeast Asia faced challenges with its turbine fuel control system: legacy single-function modules (separate analog input and output units) caused signal latency, leading to delayed valve adjustments during load changes. Additionally, frequent electromagnetic interference (EMI) in the turbine hall triggered false pressure alarms, requiring 2–3 maintenance checks weekly. After upgrading to IS220PAICH1A, the plant consolidated two modules into one, cutting signal latency by 60% and stabilizing valve control. The module’s built-in anti-interference design eliminated 90% of false alarms, while its support for HART protocol enabled remote diagnostics of smart transmitters—reducing maintenance labor by 120 hours monthly. This scenario highlights how IS220PAICH1A solves pain points of integration complexity, signal instability, and maintenance inefficiency in mission-critical power systems.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS220PAICH1A |

| Manufacturer | General Electric (GE) |

| Product Category | Analog Input/Output (I/O) Module |

| Input Channels | 16 differential analog input channels |

| Output Channels | 2 × 0–20mA current loop output channels |

| Input Signal Range | Voltage: ±10mV, ±50mV, ±100mV, ±1V, ±5V, ±10VCurrent: 4–20mA |

| Output Signal Range | 0–20mA DC (configurable for control scenarios) |

| Measurement Accuracy | ±0.1% of full scale |

| Resolution | 16-bit ADC (analog-to-digital conversion) |

| Update Rate | Configurable up to 10ms |

| Isolation Voltage | 1500Vrms (field side to backplane) |

| Communication Protocol | Supports HART protocol (for smart transmitter diagnostics) |

| Power Supply | 5V DC (backplane-powered) |

| Operating Temperature | -40°C to +85°C (wide range for extreme industrial conditions) |

| Physical Dimensions | Approximately 100mm × 50mm × 20mm |

| Weight | Approximately 2.5kg |

| Protection & Redundancy | Anti-interference design; supports single and Triple Modular Redundancy (TMR) |

| Compatible Systems | Mark VI, Mark VIe, PACSystems RX7i |

IS220PAICH1A

Technical Principles and Innovative Values

Innovation Point 1: Integrated I/O with Multi-Range FlexibilityUnlike discrete input/output modules that require separate hardware, IS220PAICH1A combines 16 input and 2 output channels in one unit, reducing rack space by 50% in control cabinets . Each input channel is software-configurable for 7+ signal ranges (from ±10mV to ±10V voltage, 4–20mA current), eliminating the need for signal conditioners and supporting diverse sensors (thermocouples, pressure transmitters) in a single system.

Innovation Point 2: HART-Enabled Predictive DiagnosticsThe module’s HART protocol support enables two-way communication with smart transmitters—allowing remote reading of diagnostic data (e.g., sensor drift, wiring faults) without on-site inspection . This shifts maintenance from reactive to predictive: a European refinery using the module detected a failing pressure transmitter 72 hours before failure, avoiding an unplanned shutdown costing $180,000.

Innovation Point 3: Extreme Reliability for Harsh EnvironmentsWith an operating temperature range of -40°C to +85°C (wider than the industry average of -25°C to +70°C) and robust anti-interference design, the module maintains accuracy in high-vibration turbine halls, humid chemical plants, and cold offshore platforms . Its support for TMR configurations further ensures system uptime in safety-critical applications like nuclear power auxiliary systems.

Application Cases and Industry Value

Case 1: Petroleum Chemical Plant Process ControlA Chinese petrochemical plant deployed IS220PAICH1A in its catalytic cracking unit to monitor 12 temperature/pressure sensors (via analog inputs) and control 2 fuel flow valves (via 0–20mA outputs). Legacy modules suffered from cross-talk, causing valve “hunting” and 5% fuel waste. The module’s isolation and anti-interference design eliminated cross-talk, while HART diagnostics reduced transmitter maintenance by 40%. Over six months, fuel costs dropped by $90,000, and product 合格率 rose to 98% .

Case 2: Substation Power MonitoringA North American utility integrated IS220PAICH1A into its substation smart grid system to collect voltage/current signals from 16 transformers. The module’s ±0.1% accuracy ensured precise load monitoring, while its TMR redundancy prevented data loss during power fluctuations. When an abnormal current spike was detected, the module triggered a protective shutdown in 8ms—avoiding a transformer failure that would have caused a 12-hour blackout for 5,000 customers .

Related Product Combination Solutions

GE IS220UCSAH1A: Universal controller module that processes input data from IS220PAICH1A and sends control commands to its output channels, enabling closed-loop control (e.g., pressure → valve adjustment).

GE IS200TBACH1A: Terminal board that conditions analog signals and provides secure wiring termination for the module’s 16 input channels, ideal for long cable runs in refineries.

GE DS200TPSAG1A: Redundant power supply that stabilizes the 5V backplane power for IS220PAICH1A, preventing signal loss during voltage sags.

GE Rosemount 3051: Smart pressure transmitter paired with the module—HART communication enables remote diagnostics and calibration.

GE IC660HHM501: Handheld tool for verifying the module’s input/output accuracy and HART communication integrity during routine maintenance.

IS220PAICH1A

Installation, Maintenance, and Full-Cycle Support

Installing IS220PAICH1A is streamlined by its compact design and backplane power supply—no external wiring for power is required. Prior to installation, confirm compatibility with Mark VI/Vie firmware (v7.0+) and use ESD-safe tools to avoid component damage. Wiring connects via compatible terminal boards (e.g., IS200TBACH1A), with software configuration for signal ranges via the Mark VIe HMI.

Routine maintenance involves monthly checks of status LEDs (power, communication, channel faults) and quarterly HART diagnostic scans via the controller. The module’s hot-swap capability (in TMR systems) allows replacement without system shutdown. GE backs IS220PAICH1A with a 1-year warranty, 24/7 global technical support, and OEM-certified repairs that restore modules to factory specifications.

Call to Action

Whether you’re optimizing turbine fuel control, enhancing chemical process precision, or building reliable power monitoring systems, GE IS220PAICH1A delivers integrated functionality, extreme durability, and predictive intelligence. Contact us for a customized solution tailored to your analog I/O needs, and let our expertise maximize your system’s efficiency and uptime.