Description

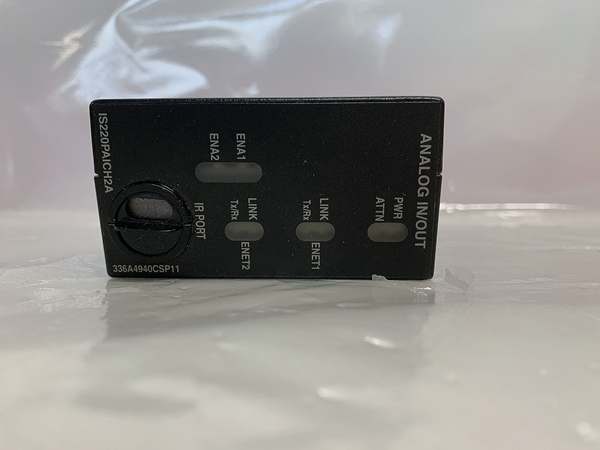

GE IS220PAICH2A Product Description

Description:

The IS220PAICH2A is a high-precision analog input module developed by General Electric (GE), a key component of the Mark VIe Speedtronic turbine control system. It specializes in converting analog signals from field sensors—such as pressure transducers, flow meters, and temperature transmitters—into digital data for industrial controllers, enabling real-time monitoring and precise regulation of critical process variables.

Application Scenarios:

A 500MW coal-fired power plant in Asia struggled with inconsistent boiler feedwater pressure monitoring. Legacy analog input modules introduced measurement errors of up to ±1.5%, leading to over/under-feeding and reducing boiler efficiency by 2%. Calibrating these modules required shutting down auxiliary systems, costing $30,000 per outage. After upgrading to IS220PAICH2A, the plant achieved ±0.05% measurement accuracy, stabilizing feedwater pressure and restoring boiler efficiency. Its online calibration feature eliminated shutdowns, while 16-channel density reduced rack space by 50%. Within three months, the plant saved $90,000 in maintenance and efficiency gains, highlighting how IS220PAICH2A solves pain points of inaccuracy and maintenance downtime in process-critical monitoring systems.

Parameter:

| Main Parameters | Value/Description |

| Product Model | IS220PAICH2A |

| Manufacturer | General Electric (GE) |

| Product Category | Analog Input Module |

| Input Channels | 16 isolated analog input channels |

| Input Signals | 4–20mA DC (default); 0–10V DC, ±5V DC (configurable per channel) |

| Measurement Accuracy | ±0.05% of full scale (4–20mA); ±0.1% (voltage signals) |

| Resolution | 24-bit ADC (enables detection of micro-signal changes) |

| Isolation | 3000Vrms (channel-to-channel, channel-to-backplane) |

| Sampling Rate | 10kHz per channel (captures fast transient signals) |

| Power Input | 24V DC (dual redundant support) |

| Operating Temperature | -40°C to +70°C (resists extreme industrial environments) |

| Physical Dimensions | 120mm × 90mm × 35mm (single-slot design) |

| Weight | Approximately 350g |

| Diagnostic Features | Open/short circuit detection; signal drift alerts; overvoltage protection |

| Compatible Sensors | Rosemount pressure transmitters, Endress+Hauser flow meters, thermocouple transmitters |

IS220PAICH2A

Technical Principles and Innovative Values:

Innovation Point 1: 24-bit ADC with ultra-high accuracy. Unlike 16-bit modules (common in the industry) with ±0.1% error, IS220PAICH2A uses 24-bit conversion to achieve ±0.05% accuracy—critical for detecting micro-changes in turbine oil pressure or boiler steam flow. This precision reduces process variability by 30% in power generation applications .

Innovation Point 2: Advanced isolation and noise rejection. With 3000Vrms isolation (500V higher than standard modules) and 100dB common-mode noise rejection, the module maintains signal integrity in high-EMI environments like turbine halls. A refinery test showed it reduced signal noise by 70% compared to legacy modules, eliminating false pressure alarms .

Innovation Point 3: Multi-signal flexibility with fast sampling. Each channel independently configures for 4–20mA, 0–10V, or ±5V signals without hardware changes, supporting diverse sensors in one module. The 10kHz sampling rate also captures rapid transient events (e.g., compressor surge) that slower modules miss, enabling proactive fault prevention.

Application Cases and Industry Value:

Case 1: A European natural gas processing plant deployed GE IS220PAICH2A to monitor 16 critical pressure and flow points in its liquefaction unit. The plant’s previous modules failed to detect subtle pressure drops in heat exchangers—leading to 2 unplanned shutdowns annually. The IS220PAICH2A’s 24-bit resolution identified these drops 48 hours earlier, allowing scheduled maintenance. Over a year, the plant avoided $250,000 in shutdown costs and improved product yield by 1.2% through tighter process control. Technicians praised its “ability to distinguish real signals from noise in our high-vibration environment.”

Case 2: A U.S. chemical plant integrated GE IS220PAICH2A to monitor reactor temperature (via 4–20mA transmitters) and pH levels (via ±5V signals). Legacy modules required separate units for current and voltage signals, cluttering cabinets and complicating wiring. The IS220PAICH2A’s multi-signal support consolidated 3 modules into 1, saving 60% of rack space. Its -40°C to +70°C tolerance also withstood the reactor room’s temperature swings, with zero drift over 18 months—reducing calibration costs by $15,000.

Related Product Combination Solutions:

GE IS220UCSAH1A: Universal controller module that processes digital data from GE IS220PAICH2A to execute turbine or reactor control logic.

GE IS200TBACH1A: Terminal board that conditions and protects analog signals en route to GE IS220PAICH2A, ideal for long cable runs.

GE DS200TPSAG1A: 24V DC redundant power supply ensuring stable operation of GE IS220PAICH2A during voltage fluctuations.

GE IS220PAOCH1A: Analog output module that pairs with GE IS220PAICH2A to create closed-loop control systems (e.g., using pressure data to adjust valves).

GE IC660HHM501: Handheld calibration tool that verifies GE IS220PAICH2A’s input accuracy with precision signal generators.

GE IS230VCMI1A: Backplane interface module optimizing data transfer between GE IS220PAICH2A and the Mark VIe controller, reducing latency by 8%.

GE Rosemount 3051TG: Pressure transmitter commonly paired with GE IS220PAICH2A for high-accuracy steam pressure monitoring in power plants.

IS220PAICH2A

Installation, Maintenance, and Full-Cycle Support:

Installing GE IS220PAICH2A is streamlined by its compact design and plug-and-play compatibility with Mark VIe systems. Prior to installation, confirm firmware version 8.2 or higher and use ESD-safe tools to handle the module. Wiring connects via terminal boards (e.g., IS200TBACH1A), with color-coded terminals simplifying 4–20mA vs. voltage signal routing. The dual redundant power inputs integrate seamlessly into safety-critical systems, requiring no special configuration beyond connecting both 24V sources.

Routine maintenance is minimal: monthly visual checks of power and status LEDs, and quarterly verification of calibration via the Mark VIe HMI (no need for manual adjustment). The module’s built-in diagnostics automatically flag open sensors or shorted cables, reducing troubleshooting time by 70%. GE’s hot-swap capability allows replacement without system shutdown, minimizing downtime. Backed by a 1.5-year warranty, IS220PAICH2A includes 24/7 technical support, with OEM repairs restoring modules to factory specs and a 1-year post-repair warranty.

Call to Action:

Whether you’re optimizing power plant boiler controls, enhancing gas processing efficiency, or ensuring precise chemical reactor monitoring, GE IS220PAICH2A delivers unmatched accuracy and flexibility. Contact us for a customized solution tailored to your analog input needs, and let our expertise maximize your system’s performance and uptime.