Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS220PDIAH1A |

| Manufacturer | General Electric (GE) – Industrial Automation Division |

| Product category | Digital Input/Output (I/O) Module (for Discrete Signal Control in DCS) |

| Digital input channels | 16 isolated channels (sinking/sourcing configurable); Input voltage: 24 V DC |

| Digital output channels | 8 isolated channels (relay output); Output rating: 2 A @ 250 V AC / 3 A @ 30 V DC |

| Input signal response time | <1 ms (for fast event detection) |

| Output switching time | <10 ms (relay actuation/de-actuation) |

| Operating voltage | 24 V DC (power input); ±5 V DC (logic power, from Mark VIe backplane) |

| Power consumption | <5 W (typical); <8 W (max, with all outputs active) |

| Environmental operating range | Temperature: -30°C to 65°C (-22°F to 149°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤2000 m |

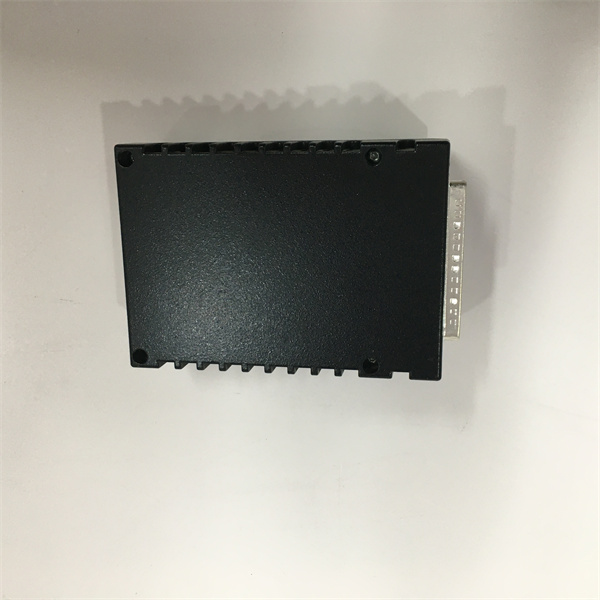

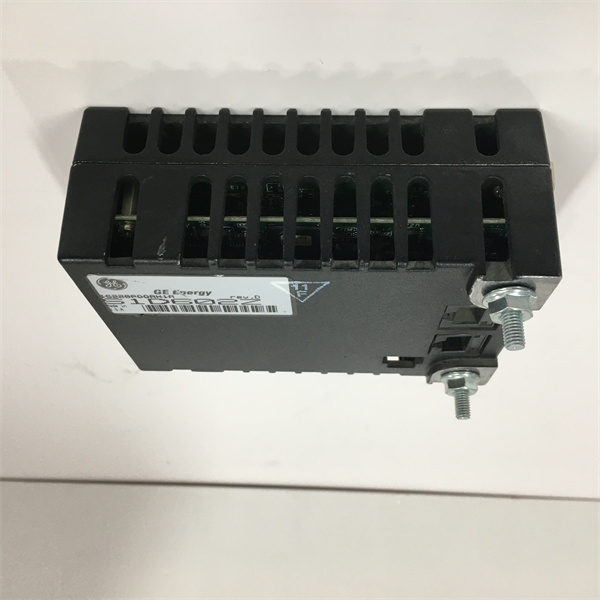

| Physical dimensions (L×W×H) | 121 mm × 82.6 mm × 41.9 mm (4.76 in × 3.25 in × 1.65 in); Rack-mountable (1U compatible) |

| Interface type | Terminal block (24 V DC power + I/O signals); RJ45 (backplane communication); DC-37 pin (logic power) |

| Weight | 600 g (1.32 lbs) – includes metal shielding for EMI protection |

| Protection features | Input overvoltage (30 V DC max), output short-circuit protection, reverse polarity protection |

| Certifications | CE (EN 61131-2), UL 508 (Industrial Control Equipment), IEC 60947-5-1 |

IS220PDIAH1A

Product Introduction

The IS220PDIAH1A is a versatile digital I/O module developed by GE for seamless integration with its Mark VIe Distributed Control System (DCS)—a platform trusted for reliability in power generation, manufacturing, and process industries. Unlike the thermocouple-focused IS220PTCCH1A, the IS220PDIAH1A specializes in handling discrete signals: it converts 24 V DC digital inputs (e.g., from limit switches, sensors) into DCS-readable data and delivers relay-driven digital outputs to control actuators, valves, or alarms. This dual functionality makes it a cornerstone of industrial control loops, bridging field devices and the Mark VIe system.

With 16 configurable digital inputs and 8 relay outputs, the IS220PDIAH1A adapts to diverse applications—from monitoring machine status to triggering emergency shutdowns. Its isolated input/output channels prevent cross-signal interference, while fast response times (<1 ms for inputs) ensure critical events (e.g., a tripped safety switch) are detected instantly. For plant operators, the IS220PDIAH1A offers flexibility and durability: it works with standard 24 V DC field devices, eliminating the need for signal converters, and its rugged design withstands harsh industrial conditions—all while maintaining GE’s rigorous quality standards.

Core Advantages and Technical Highlights

Dual-Function I/O for Space Efficiency

The IS220PDIAH1A combines 16 digital inputs and 8 digital outputs in a single 1U rack-mount module, reducing the number of slots required in Mark VIe racks compared to separate input/output modules. This space efficiency is critical in dense control cabinets—for example, a single IS220PDIAH1A can replace two dedicated modules (16-input + 8-output), freeing up space for other components like the IS220PTCCH1A (thermocouple module). The module’s configurable input channels (sinking/sourcing) further enhance flexibility, allowing it to work with any 24 V DC discrete sensor or switch.

Isolated Channels for System Protection

Every input and output channel of the IS220PDIAH1A features galvanic isolation, protecting the Mark VIe DCS backplane from voltage spikes or ground loops in field wiring. For instance, if a digital output channel experiences a short circuit (e.g., due to a faulty valve coil), the module’s isolation prevents damage to the DCS processor or adjacent modules like the IS220PTCCH1A. The output channels also include short-circuit protection, which limits current to safe levels and automatically resets once the fault is resolved—avoiding costly module replacements.

Rugged Design for Harsh Environments

Built to GE’s industrial specifications, the IS220PDIAH1A includes a metal-shielded housing that complies with EN 61000-6-2 EMI standards, blocking electromagnetic interference from motors, variable frequency drives, or nearby power cables. Its wide operating temperature range (-30°C to 65°C) and resistance to non-condensing humidity make it suitable for extreme locations: from freezing warehouse automation systems to hot chemical plant control rooms. With a mean time between failures (MTBF) exceeding 150,000 hours, the IS220PDIAH1A outperforms generic digital I/O modules, minimizing unplanned downtime and maintenance costs.

Typical Application Scenarios

In power generation plants (e.g., coal, gas, or biomass), the IS220PDIAH1A works alongside the IS220PTCCH1A to form a complete control subsystem. The IS220PDIAH1A monitors discrete inputs like boiler feedwater pump status (on/off), fuel valve position (open/closed), or safety interlock switches (tripped/normal). Its digital outputs trigger actions such as starting/stopping auxiliary pumps or activating alarm lights if the IS220PTCCH1A detects abnormal temperatures (e.g., overheating in ash handling systems). This integration ensures coordinated control, enhancing both efficiency and safety.

In manufacturing facilities (e.g., automotive assembly lines), the IS220PDIAH1A manages machine automation: its inputs track conveyor belt position sensors, part presence detectors, or emergency stop buttons, while outputs control conveyor motors, robotic grippers, or quality-check lights. Its fast input response time (<1 ms) is critical here—detecting a missing part on the conveyor instantly to pause the line, preventing defective products and reducing waste. Unlike consumer-grade I/O modules, the IS220PDIAH1A’s relay outputs handle the high currents required for industrial motors, eliminating the need for external contactors.

In food and beverage processing, the IS220PDIAH1A supports hygiene-critical operations: its inputs monitor door status on refrigerated storage units (open/closed) or level sensors in ingredient tanks (full/empty), while outputs control sanitizing pump activation or tank fill valves. Its 24 V DC operation is compatible with food-safe sensors, and its industrial certifications (UL 508, CE) ensure compliance with FDA and EU hygiene standards. When paired with the IS220PTCCH1A (monitoring pasteurization temperatures), the IS220PDIAH1A creates a closed-loop system that maintains product quality and safety.

Related Model Recommendations

IS220PTCCH1A: GE’s thermocouple input module, often paired with IS220PDIAH1A to combine temperature monitoring (analog) and discrete control (digital) in Mark VIe systems.

IS220PDIAH2A: High-density upgrade of IS220PDIAH1A, featuring 32 digital inputs and 16 digital outputs. Ideal for large-scale automation (e.g., multi-line manufacturing plants).

TBPDIA1B: Terminal board designed exclusively for IS220PDIAH1A, providing color-coded terminals for easy I/O wiring and built-in surge protection for field devices.

IS220UCSAH1A: GE’s universal analog input module, complements IS220PDIAH1A by adding support for pressure, flow, or level signals (4–20 mA/0–10 V) in mixed-signal DCS setups.

IS220PSFDH1A: GE’s power supply module, powers IS220PDIAH1A (24 V DC) and the IS220PTCCH1A (±5 V DC) in Mark VIe racks, ensuring stable voltage delivery.

IS220PDIAH1B: Solid-state output variant of IS220PDIAH1A (8 solid-state outputs instead of relays), suitable for high-cycle applications (e.g., 100,000+ switching cycles) like packaging machines.

IC695PBM300: GE Fanuc PLC module, enables communication between Mark VIe DCS (with IS220PDIAH1A) and Fanuc PLCs in hybrid automation systems.

IS220PDIAH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation for IS220PDIAH1A starts with verifying compatibility: ensure the Mark VIe rack has an available 1U slot and that the 24 V DC power supply (from IS220PSFDH1A or equivalent) has a ripple voltage <100 mV (use a multimeter). Gather tools: torque screwdriver (0.5–1.0 N·m for terminal blocks), wire strippers (for 14–22 AWG field wires), and a continuity tester (to verify wiring before power-up). Always power down the Mark VIe rack before inserting the IS220PDIAH1A—its relay outputs can cause arcing if hot-swapped.

For commissioning, use the Mark VIe HMI to configure input channels (sinking/sourcing) and output logic (e.g., normally open/normally closed). Test each input by activating field devices (e.g., pressing a limit switch) and confirming signal detection in the DCS. For outputs, trigger each relay via the HMI and verify load activation (e.g., a valve opening) using a current clamp meter.

For maintenance, conduct monthly checks: inspect the IS220PDIAH1A’s LED indicators (green = normal; red = fault; amber = communication error) and tighten terminal block screws (to prevent loose connections). Every 12 months, test relay output contacts for wear using a multimeter (measure resistance—should be <1 Ω when closed). If replacement is needed, use only GE-authorized IS220PDIAH1A spares (verify part numbers via GE’s portal) to maintain Mark VIe compatibility. Post-replacement, re-run commissioning tests to ensure all channels function correctly.

Service and Guarantee Commitment

The IS220PDIAH1A is backed by GE’s 24-month manufacturer warranty, covering defects in materials, workmanship, and relay wear under normal operating conditions. This warranty includes free replacement of faulty modules and is transferable to subsequent owners if installed and maintained per GE’s guidelines—reflecting GE’s confidence in the module’s durability.

GE provides 24/7 global technical support for the IS220PDIAH1A: customers can access specialists via phone, email, or GE’s industrial support portal for help with configuration, troubleshooting, or integration with the IS220PTCCH1A and other Mark VIe modules. The portal offers free resources: IS220PDIAH1A user manuals, wiring diagrams, and video tutorials on commissioning. For extended protection, GE offers service contracts (1–5 years) that include annual preventive maintenance (relay contact testing, firmware updates) and priority spare parts shipping (24–48 hour delivery in major regions). All service work is performed by GE-certified technicians to ensure the module’s performance and warranty validity.