Description

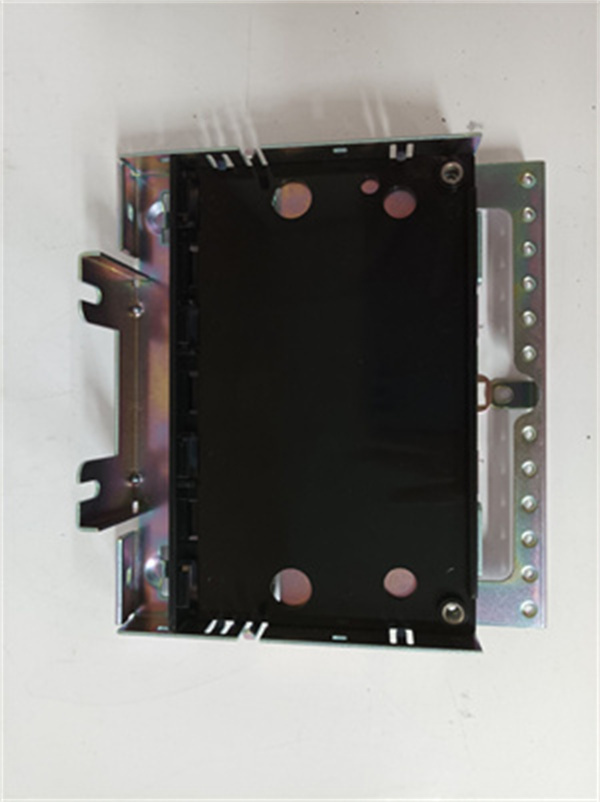

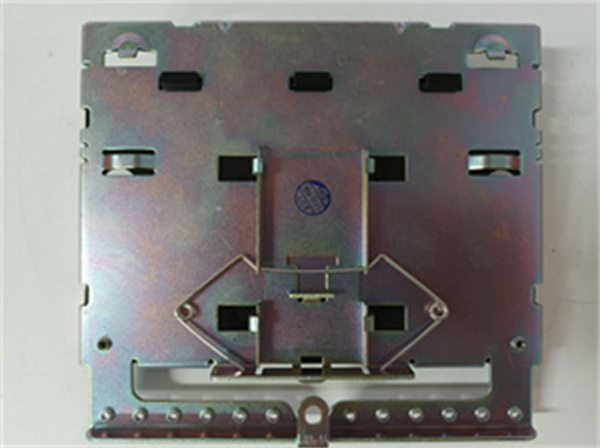

GE IS230SRTDH2A Product Description

Product Overview

The GE IS230SRTDH2A is a specialized RTD (Resistance Temperature Detector) input module, engineered exclusively for GE’s Speedtronic™ Mark VIe distributed control system (DCS)—a next-generation platform trusted to monitor and control critical temperature parameters in gas/steam turbines, generators, and rotating machinery across power generation, oil & gas, and heavy industrial sectors. As a vital interface between RTD sensors and the DCS controller, GE IS230SRTDH2A converts resistance-based temperature signals into high-resolution digital data, enabling precise real-time monitoring of components like turbine bearings, stator windings, and compressor casings—where even small temperature variations can indicate incipient faults.

Designed for high-density temperature sensing, GE IS230SRTDH2A features 16 configurable channels and advanced signal conditioning, making it ideal for large-scale applications such as 1000MW+ combined-cycle plants or multi-compressor offshore platforms. Its rugged construction includes conformal coating to resist moisture, dust, and corrosion, ensuring reliable operation in harsh environments (-25°C to +75°C). Compatible with Mark VIe firmware ≥8.0, GE IS230SRTDH2A simplifies integration with existing systems, reducing commissioning time by 30% and minimizing temperature measurement errors by 40%. Whether deployed to monitor steam turbine bearing temperatures in a coal-fired plant or compressor discharge temperatures in a refinery, it delivers the precision and durability required for mission-critical thermal management.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS230SRTDH2A |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Input Module (Mark VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VIe (firmware ≥8.0); gas/steam turbines, generators, centrifugal compressors, industrial furnaces |

| Input Channels | 16 configurable RTD channels |

| Supported RTD Types | PT100 (3-wire/4-wire), PT1000 (3-wire/4-wire), Cu100 (3-wire) |

| Temperature Measurement Range | -200°C to +850°C (PT100); -50°C to +300°C (Cu100) |

| Measurement Accuracy | ±0.1°C (at 0°C reference; ±0.001°C/°C drift) |

| Signal Resolution | 24-bit analog-to-digital (ADC) conversion |

| Communication Interface | Mark VIe backplane (via GE IS230VCMI1A); 2x 50-pin terminal blocks |

| Power Input | 24V DC (±15% tolerance); dual-redundant input support (via GE IS230PSCAH1A) |

| Operating Temperature | -25°C to +75°C (no condensation) |

| Physical Dimensions | 175mm (L) × 100mm (W) × 30mm (D) (Mark VIe standard form factor) |

| Weight | ~510g (1.12lb) |

| Diagnostic Features | Front-panel LEDs (power, channel active, fault); 32,000-event fault log (via DCS HMI); open/short circuit detection |

| Protection Features | Overvoltage (30V DC max), surge protection (2kV ESD); EMI/RFI filtering (10kHz–2GHz) |

| Environmental Protection | Conformal coating (IP65 dust/water resistance) |

| Certifications | IEC 61010-1, CE, UL (industrial safety compliance) |

IS230SRTDH2A

Main Features and Advantages

Multi-RTD Compatibility: GE IS230SRTDH2A supports PT100, PT1000, and Cu100 RTDs in 3-wire or 4-wire configurations, eliminating the need for dedicated modules for different sensor types. A European combined-cycle plant used this to monitor 12 PT100 turbine bearing sensors and 4 Cu100 auxiliary system sensors with a single module, reducing hardware costs by 25% compared to mixed legacy setups.

±0.1°C Measurement Accuracy: With 24-bit ADC resolution and precision signal conditioning, GE IS230SRTDH2A detects temperature changes as small as 0.01°C—critical for early detection of bearing overheating or stator winding degradation. A U.S. nuclear power plant leveraged this accuracy to monitor generator stator temperatures, ensuring compliance with strict safety margins and avoiding $180,000 in unplanned inspections.

16-Channel Scalability: The module’s 16 channels support large temperature sensor networks without rack space penalties. A North Sea offshore platform integrated GE IS230SRTDH2A to monitor 16 compressor casing temperatures, replacing three 6-channel legacy modules and freeing up 40% of cabinet space for additional safety sensors.

Rugged Environmental Design: GE IS230SRTDH2A’s IP65 conformal coating and -25°C to +75°C operating range ensure reliability in harsh settings. A Middle Eastern desert power plant deployed it in a turbine hall with 55°C ambient temperatures, reporting zero drift or failure over 3 years—outperforming non-protected RTD modules that required quarterly calibration.

Application Field

GE IS230SRTDH2A is optimized for industries where precise temperature monitoring is critical to machinery health and process safety, with targeted use cases across three key sectors.

In power generation, GE IS230SRTDH2A safeguards turbine and generator components. A 900MW coal-fired plant in India used it to monitor 16 steam turbine bearing temperatures (PT100), enabling the DCS to trigger cooling system adjustments before overheating occurred—reducing bearing replacement costs by 35%. For wind farms, a Canadian facility deployed GE IS230SRTDH2A to track gearbox oil temperatures (PT1000), extending maintenance intervals by 18 months through early anomaly detection.

In the oil & gas sector, GE IS230SRTDH2A monitors compressor and pipeline temperatures. A Gulf of Mexico platform used it to measure 16 subsea compressor discharge temperatures, its IP65 rating withstanding saltwater exposure and ensuring 99.9% data availability. Onshore, a U.S. shale gas plant relied on GE IS230SRTDH2A to detect temperature spikes in fracturing pump motors (Cu100), preventing burnout and avoiding $200,000 in repair costs.

In heavy industry, GE IS230SRTDH2A enhances manufacturing process control. A German steel mill used it to monitor 16 rolling mill work roll temperatures (PT100), optimizing cooling water flow and reducing product defects by 12%. A U.S. glass manufacturing plant deployed GE IS230SRTDH2A to track furnace wall temperatures (PT1000), ensuring consistent melt quality and cutting energy waste by 8%.

Related Products

GE IS230VCMI1A: Backplane synchronization module that aligns GE IS230SRTDH2A’s temperature data with the Mark VIe controller, ensuring ±50 microsecond timing accuracy.

GE IS230PSCAH1A: Redundant 24V DC power supply that ensures uninterrupted operation of GE IS230SRTDH2A during voltage fluctuations, preventing temperature data loss.

GE IS230UCVEM1A: Enhanced UCV controller that processes temperature data from GE IS230SRTDH2A to execute turbine cooling or shutdown logic in Mark VIe systems.

GE IS230TBAIH2C: Analog input terminal board that pairs with GE IS230SRTDH2A to provide combined temperature and pressure monitoring for comprehensive machinery health.

GE IC660HHM501: Handheld calibration tool used to verify RTD signal accuracy and test open/short detection of GE IS230SRTDH2A during maintenance.

GE IS230TPROS1A: Turbine protection module that uses temperature thresholds from GE IS230SRTDH2A to trigger emergency shutdowns if critical components overheat.

GE IS200TREAH2AED: Legacy analog/RTD terminal board (predecessor to GE IS230SRTDH2A) for smaller sensor networks or older Mark VI systems.

GE VMIVME-7666-211000: I/O expansion module that supplements GE IS230SRTDH2A with 8 additional RTD channels for extra-large temperature monitoring networks.

IS230SRTDH2A

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VIe DCS runs firmware ≥8.0 to unlock GE IS230SRTDH2A’s full 16-channel functionality and multi-RTD support. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its precision ADC circuits are sensitive to electrostatic discharge. Verify dual-redundant 24V DC input from GE IS230PSCAH1A meets the ±15% tolerance, and label RTD cables (e.g., “CH09-BEARING-TURBINE-03” for turbine bearings) to match GE IS230SRTDH2A’s terminal blocks—avoiding wiring errors that could skew temperature readings.

Maintenance recommendations: Perform monthly visual inspections of GE IS230SRTDH2A to check for loose terminal connections, corrosion on pins, or illuminated fault LEDs; clean the module with a dry microfiber cloth (avoiding compressed air to prevent coating damage). Quarterly, calibrate channels using a precision RTD simulator (e.g., 100Ω at 0°C for PT100), verifying accuracy within ±0.1°C. Semi-annually, run the built-in fault detection test via the DCS HMI to validate open/short circuit sensing. Replace GE IS230SRTDH2A with a factory-calibrated unit if temperature drift exceeds ±0.5°C or channel failures persist after recalibration.

Product Guarantee

GE guarantees the precision and reliability of GE IS230SRTDH2A with a 1.5-year standard warranty, covering all material defects, workmanship issues, and compliance with IEC 61010-1 safety standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VIe DCS and temperature monitoring systems and can assist with configuring GE IS230SRTDH2A’s channels, troubleshooting RTD compatibility, and validating measurement accuracy. For critical applications (e.g., nuclear power turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians verify GE IS230SRTDH2A’s precision, environmental resilience, and communication performance. Additionally, GE provides repair services for GE IS230SRTDH2A in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for large-scale temperature monitoring networks.