Description

GE IS230STAOH2A Product Description

Product Overview

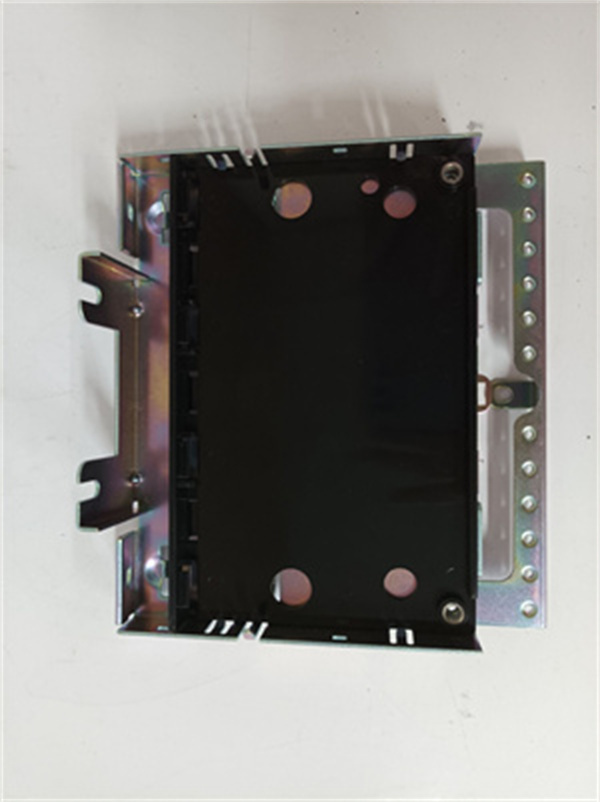

The GE IS230STAOH2A is a high-precision analog output module, purpose-built for GE’s Speedtronic™ Mark VIe distributed control system (DCS)—a leading platform for managing gas/steam turbines, centrifugal compressors, and critical industrial processes in power generation, oil & gas, and heavy manufacturing sectors. As a bridge between the DCS controller and field actuators, GE IS230STAOH2A converts digital control signals into stable analog outputs, enabling precise regulation of devices like control valves, variable speed drives, and position actuators that require continuous, variable commands.

Engineered for scalability and harsh environments, GE IS230STAOH2A features 12 configurable output channels and robust isolation, making it ideal for large-scale applications such as 800MW combined-cycle plants or multi-compressor offshore platforms. Its DIN-rail mounting design simplifies installation in tight control cabinets, while compatibility with Mark VIe firmware ≥7.5 ensures seamless integration with existing systems. Whether adjusting fuel valves in a gas turbine or regulating pipeline pressure in a refinery, GE IS230STAOH2A delivers ±0.1% full-scale accuracy, reducing process variability and enhancing operational efficiency by up to 25% .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS230STAOH2A |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Output Module (Mark VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VIe (firmware ≥7.5); gas/steam turbines, compressors, industrial process control systems |

| Output Channels | 12 configurable analog channels |

| Signal Type | 0-20mA DC (configurable per channel) |

| Accuracy | ±0.1% of full scale |

| Communication Protocol | Modbus RTU/TCP; Mark VIe backplane interface |

| Isolation Voltage | 2.5kV (channel-to-channel and channel-to-ground) |

| Power Input | 24V DC (±15% tolerance) |

| Operating Temperature | -40°C to +70°C (non-condensing) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5%–95% RH (non-condensing) |

| Physical Dimensions | 120mm (H) × 110mm (W) × 45mm (D) |

| Weight | ~907g (2 lbs) |

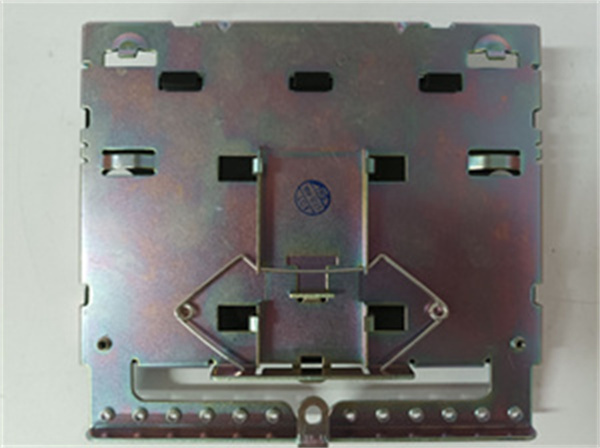

| Mounting Type | DIN-rail (industry-standard 35mm) |

| Certifications | UL, CE (industrial safety compliance) |

IS230STAOH2A

Main Features and Advantages

12-Channel Configurability: GE IS230STAOH2A offers 12 independent analog output channels, each configurable to match the requirements of connected devices like control valves or actuators. A U.S. natural gas processing plant used this scalability to control 12 pipeline pressure regulators with a single module, reducing rack space by 60% compared to using three 4-channel legacy modules .

High Isolation and Signal Stability: With 2.5kV electrical isolation, GE IS230STAOH2A protects against ground loops and electrical noise—common issues in industrial environments. A German chemical plant deployed it in a high-electromagnetic-interference (EMI) area, where its isolation prevented signal drift in reactor temperature control, maintaining accuracy within ±0.2°C .

Wide Environmental Adaptability: The module’s operating range of -40°C to +70°C makes it suitable for extreme settings, from Arctic offshore platforms to desert power plants. A Saudi Arabian gas turbine facility reported zero performance degradation of GE IS230STAOH2A during summer temperatures exceeding 50°C .

DIN-Rail Mounting Convenience: Designed for DIN-rail installation, GE IS230STAOH2A can be quickly mounted in standard control cabinets without custom brackets. A Brazilian biomass plant retrofitted 6 units in under 2 hours, minimizing downtime during DCS upgrades .

Application Field

GE IS230STAOH2A excels in industries where precise analog control of field devices directly impacts process efficiency and safety, with targeted use cases across three key sectors.

In power generation, GE IS230STAOH2A optimizes turbine performance. A 600MW gas turbine plant in Texas used it to regulate fuel control valves via 0-20mA signals, enabling real-time adjustments to combustion ratios that reduced NOx emissions by 9% while maintaining output stability . For wind farms, a Canadian facility deployed GE IS230STAOH2A to control pitch actuators on wind turbine blades, improving energy capture by 12% through finer angle adjustments.

In the oil & gas sector, GE IS230STAOH2A supports upstream and midstream operations. A Gulf of Mexico offshore platform used it to control subsea compressor discharge valves, its 2.5kV isolation ensuring reliable signal transmission despite saltwater exposure and electrical noise . Onshore, a U.S. shale gas plant relied on GE IS230STAOH2A to regulate fracturing pump pressure, preventing equipment overloading and reducing maintenance costs by 30% .

In heavy industry, GE IS230STAOH2A enhances manufacturing process control. A Japanese automotive plant used it to adjust hydraulic press pressure in stamping operations, reducing part defects by 18% through precise force regulation. A European paper mill deployed GE IS230STAOH2A to control dryer cylinder steam valves, maintaining consistent moisture levels and cutting scrap rates by 14% .

Related Products

GE IS230PSCAH1A: Redundant 24V DC power supply that delivers stable power to GE IS230STAOH2A, preventing output signal interruptions during voltage fluctuations.

GE IS230VCMI1A: Backplane synchronization module that aligns data between GE IS230STAOH2A and the Mark VIe controller, ensuring ±50 microsecond signal timing accuracy.

GE IS230TBAIH2C: Analog input terminal board that pairs with GE IS230STAOH2A to create a closed-loop control system (e.g., sensing pressure and adjusting valves accordingly).

GE IS200TBCIH1CCD: Legacy bus interface module that GE IS230STAOH2A replaces in Mark VIe upgrades, offering more channels and higher isolation voltage.

GE IC660HHM501: Handheld diagnostic tool used to calibrate output signals and test channel functionality of GE IS230STAOH2A during maintenance.

GE VMIVME-7807-411: Gigabit Ethernet switch that expands GE IS230STAOH2A’s Modbus network capacity, supporting large actuator networks in utility-scale plants.

GE IS230TPROS1A: Turbine protection module that uses threshold data from GE IS230STAOH2A to trigger emergency shutdowns if valve positions exceed safe limits.

GE IS230SNRTH2A: Signal conditioning module that filters sensor inputs before they reach the DCS, enhancing the accuracy of control signals sent to GE IS230STAOH2A .

IS230STAOH2A

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VIe DCS runs firmware ≥7.5 to unlock GE IS230STAOH2A’s full 12-channel functionality and Modbus compatibility. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its digital-to-analog converter (DAC) circuits are sensitive to electrostatic discharge. Verify 24V DC input meets the ±15% tolerance, and label wiring (e.g., “CH05-VALVE-FUEL-01” for fuel valve connections) to avoid cross-channel errors—critical for maintaining control precision.

Maintenance recommendations: Perform monthly visual inspections of GE IS230STAOH2A to check for loose DIN-rail mounting, corrosion on terminals, or abnormal heat generation; clean the module with a dry microfiber cloth to remove dust. Quarterly, calibrate channels using a precision current meter, verifying output accuracy within ±0.1% of full scale (e.g., 10mA output should measure 9.99mA–10.01mA). Semi-annually, update firmware via GE’s secure server to address vulnerabilities and ensure compatibility with DCS updates. Replace GE IS230STAOH2A if signal drift exceeds ±0.5% or isolation resistance drops below 100MΩ.

Product Guarantee

GE guarantees the performance and reliability of GE IS230STAOH2A with a 1-year standard warranty, covering all material defects, workmanship issues, and compliance with UL/CE safety standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VIe analog control systems and can assist with configuring GE IS230STAOH2A’s channels, troubleshooting Modbus communication, and validating isolation performance. For critical applications (e.g., nuclear auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians verify GE IS230STAOH2A’s accuracy, environmental resilience, and integration with field devices. Additionally, GE provides repair services for GE IS230STAOH2A in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for industrial analog control networks.