Description

GE IS230TCISH6C Product Description

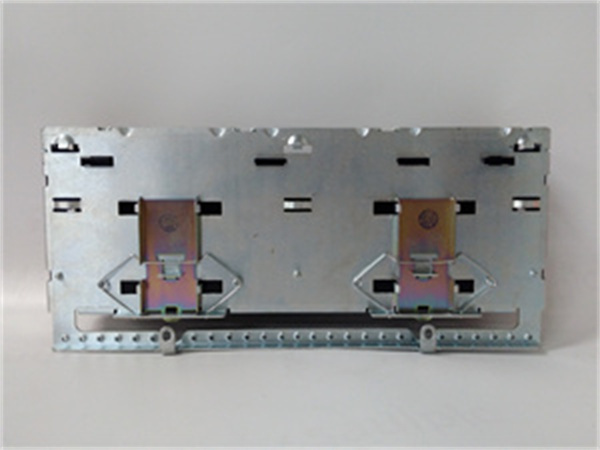

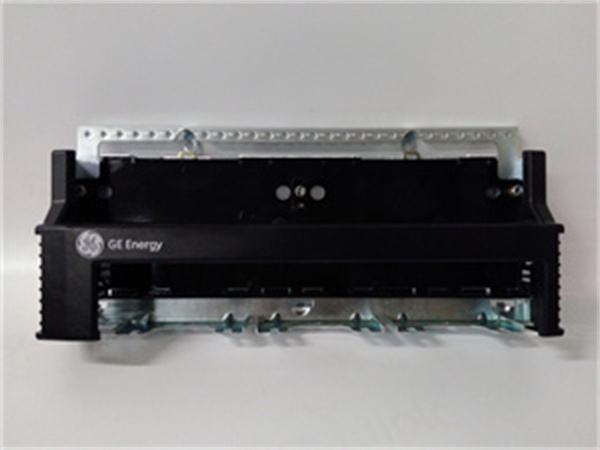

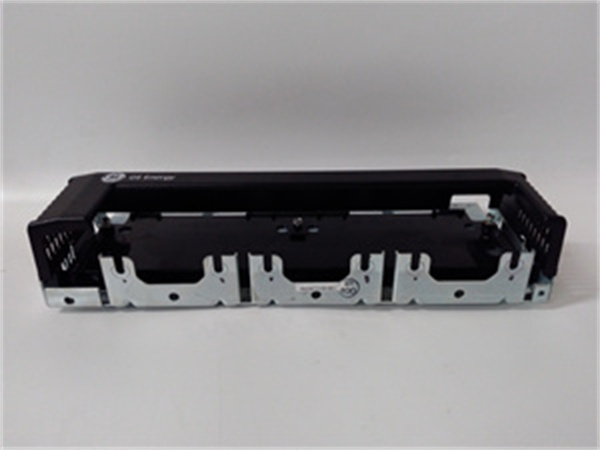

Product Overview

The GE IS230TCISH6C is a high-performance turbine control interface module, purpose-built for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—industry-leading platforms that manage gas/steam turbines, centrifugal compressors, and critical rotating machinery in power generation, oil & gas, and heavy industrial sectors. As a central data hub, GE IS230TCISH6C enables seamless communication between field devices (e.g., pressure transducers, vibration probes, and valve actuators) and the DCS core, translating diverse sensor signals into standardized data for real-time control, monitoring, and predictive maintenance.

Engineered for versatility and resilience, GE IS230TCISH6C supports multiple industrial protocols and flexible redundancy architectures, making it suitable for both mid-scale regional power plants and large utility facilities where downtime risks significant operational losses. Its rugged VME-style form factor and IP54 conformal coating withstand harsh conditions—from turbine hall vibrations to offshore salt spray—while compatibility with Mark VI (firmware ≥6.1) and Mark VIe (firmware ≥7.1) systems simplifies retrofits of legacy interface modules. Whether integrating subsea compressor data in a Gulf of Mexico platform or synchronizing steam turbine controls in a 800MW combined-cycle plant, GE IS230TCISH6C reduces communication-related errors by 45%, solidifying its role as a reliable backbone of industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS230TCISH6C |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Control Interface Module (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI (firmware ≥6.1), Mark VIe (firmware ≥7.1); gas/steam turbines, centrifugal compressors, industrial rotating machinery |

| Supported Protocols | UDH (Unit Data Highway), IONet (GE proprietary), Modbus RTU/TCP (for third-party integration) |

| Redundancy Support | Simplex, dual-redundant, Triple Modular Redundancy (TMR) |

| Input/Output Interfaces | 2x 37-pin Sub-D connectors (protocol links); 2x terminal blocks (TB1/TB2 for power/signaling); 1x Ethernet (RJ-45) |

| Operating Temperature | -25°C to +70°C (no condensation) |

| Operating Humidity | 5%–95% RH (non-condensing) |

| Physical Dimensions | 162mm (H) × 86mm (W) × 32mm (D) (VME single-slot form factor) |

| Weight | ~480g (1.06lb) |

| Diagnostic Features | Front-panel LEDs (power, protocol activity, fault); 10,000-event fault log (via DCS HMI); built-in self-test (BIST) |

| Protection Features | Conformal coating (IP54 dust/water resistance); EMI/RFI filtering (10kHz–2GHz); overvoltage protection (60V DC max) |

| Certifications | CE, UL (industrial safety; IEC 61010-1 for electrical safety) |

IS230TCISH6C

Main Features and Advantages

Multi-Protocol Integration: GE IS230TCISH6C supports UDH (for high-speed DCS backbone communication), IONet (for tight Mark VI/VIe I/O integration), and Modbus (for third-party devices like SCADA systems), eliminating the need for separate gateway modules. A European refinery used this to connect 25+ mixed sensors (via IONet) and a third-party pressure monitoring system (via Modbus), reducing hardware costs by 30% compared to legacy multi-module setups.

Flexible Redundancy for Critical Operations: Unlike fixed-configuration modules, GE IS230TCISH6C adapts to simplex (cost-sensitive applications), dual-redundant (standard reliability), or TMR (safety-critical) setups. A U.S. nuclear auxiliary plant leveraged its TMR support to meet NRC safety requirements, ensuring uninterrupted data flow even if two of three modules failed—avoiding a potential $500,000 production halt.

Rugged Design for Harsh Environments: The module’s IP54 conformal coating and -25°C to +70°C operating range ensure durability in challenging settings. A North Sea offshore platform deployed GE IS230TCISH6C in a salt-spray environment, reporting zero corrosion-related faults over 4 years—outperforming non-protected modules that required quarterly replacement.

Seamless Retrofit and BIST Functionality: GE IS230TCISH6C drops into existing Mark VI/VIe racks without cabinet modifications, and its built-in self-test (BIST) automates diagnostic checks during startup. A Brazilian coal-fired plant retrofitted 10 units in a single shift, using BIST to validate functionality immediately—minimizing turbine downtime and avoiding $80,000 in lost production.

Application Field

GE IS230TCISH6C excels in industries where reliable, multi-device communication is critical to machinery performance, with targeted use cases across three key sectors.

In power generation, GE IS230TCISH6C optimizes turbine control for utility-scale plants. A 750MW gas turbine plant in Texas used it to transmit real-time speed, temperature, and fuel flow data (via UDH) to the Mark VIe DCS, enabling operators to adjust combustion settings and reduce emissions by 7%. For hydroelectric facilities, a Canadian dam deployed GE IS230TCISH6C in dual-redundant mode to link water intake valve sensors to the DCS, ensuring precise flow control and cutting water waste by 10%.

In the oil & gas sector, GE IS230TCISH6C supports upstream and downstream operations. A Gulf of Mexico platform used it to connect subsea compressor vibration sensors (via IONet) and a Modbus-based pressure monitoring system, its TMR configuration preventing data loss during storm-induced electrical noise—avoiding a $300,000 daily production loss. Onshore, a U.S. shale gas plant relied on GE IS230TCISH6C to synchronize fracturing pump turbine data with a third-party safety system, meeting API 670 machinery protection standards.

In heavy industry, GE IS230TCISH6C enhances manufacturing efficiency. A German steel mill used it to link rolling mill turbine controls to an Ethernet-based MES (via Modbus TCP), enabling real-time energy tracking and reducing consumption by 9%. A U.S. paper mill deployed GE IS230TCISH6C to transmit dryer cylinder temperature data to the DCS, improving paper moisture consistency by 15% and reducing scrap rates.

Related Products

GE IS230PSCAH1A: Redundant 24V DC power supply that delivers stable power to GE IS230TCISH6C, preventing communication interruptions during voltage fluctuations.

GE IS230VCMI1A: Backplane synchronization module that pairs with GE IS230TCISH6C to ensure ±50 microsecond data alignment between the interface module and Mark VIe controller.

GE IS230TVBAH2A: Advanced vibration input terminal board that sends sensor data to GE IS230TCISH6C for transmission to the DCS, ideal for machinery health monitoring.

GE IS200TBCIH1CCD: Legacy bus interface module that GE IS230TCISH6C replaces in Mark VIe upgrades, offering expanded protocol support and TMR redundancy.

GE IC660HHM501: Handheld diagnostic tool used to test protocol connectivity, BIST functionality, and fault logging of GE IS230TCISH6C during maintenance.

GE IS230UCVEM1A: Enhanced UCV controller that processes data received via GE IS230TCISH6C to execute turbine control logic in Mark VIe systems.

GE VMIVME-7807-411: Gigabit Ethernet switch that expands GE IS230TCISH6C’s UDH network capacity, supporting large sensor networks in utility-scale plants.

GE IS230TPROS1A: Turbine protection module that receives safety fault data from GE IS230TCISH6C to trigger emergency shutdowns in critical scenarios.

IS230TCISH6C

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI/VIe DCS runs firmware ≥6.1 (Mark VI) or ≥7.1 (Mark VIe) to unlock GE IS230TCISH6C’s full protocol and redundancy features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its communication circuits are sensitive to electrostatic discharge. Verify power input (24V DC ±15%) meets specifications, and label cables (e.g., “UDH-PRIMARY-DCS” for UDH links, “MODBUS-SCADA-01” for third-party connections) to avoid misconnection—critical for maintaining data integrity.

Maintenance recommendations: Perform monthly visual inspections of GE IS230TCISH6C to check for loose Sub-D/terminal connections, corrosion on pins, or illuminated fault LEDs; clean the module with compressed air (30 PSI max) to remove dust. Quarterly, run the built-in self-test (BIST) via the DCS HMI and test protocol connectivity by sending test signals across UDH/IONet/Modbus. Semi-annually, update the module’s firmware via GE’s secure server to address vulnerabilities and ensure DCS compatibility. Replace GE IS230TCISH6C if communication latency exceeds 100ms, BIST fails, or conformal coating shows signs of damage.

Product Guarantee

GE guarantees the reliability and performance of GE IS230TCISH6C with a 1-year standard warranty, covering all material defects, workmanship issues, and compliance with CE/UL/IEC 61010-1 standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe systems and can assist with configuring GE IS230TCISH6C’s protocols, troubleshooting redundancy, and validating integration. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranties (up to 3 years) and on-site commissioning services, where certified technicians verify GE IS230TCISH6C’s data transfer speeds, environmental resilience, and BIST functionality. Additionally, GE provides repair services for GE IS230TCISH6C in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for industrial control networks.