Description

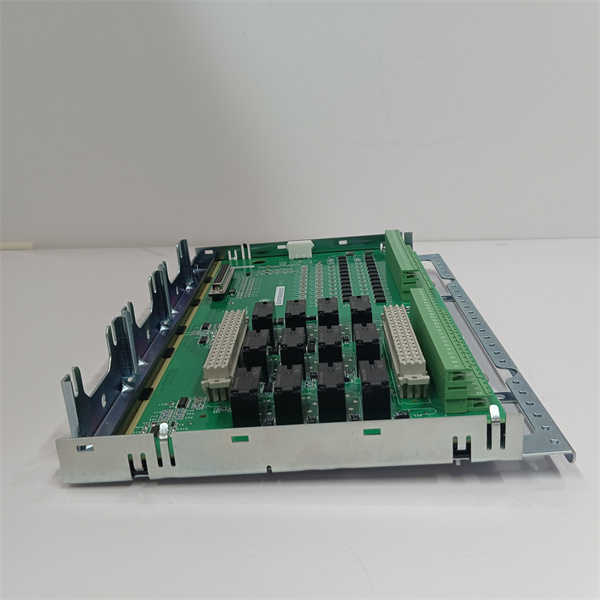

IS230TNPAH2A Product Description

Description

The IS230TNPAH2A is a high-precision turbine parameter acquisition module developed by General Electric (GE), exclusively engineered for the Speedtronic Mark VIe turbine control system—a cornerstone of reliable operation for gas, steam, and combined-cycle turbines in power generation, oil & gas, and industrial infrastructure. It acts as the “data acquisition hub” for critical turbine operating parameters, collecting and conditioning signals from speed probes, pressure transducers, temperature sensors, and vibration monitors, then delivering filtered, real-time data to the Mark VIe controller. This ensures accurate turbine performance monitoring, load optimization, and early fault detection—essential for maximizing efficiency and minimizing unplanned downtime.

Application Scenarios

A 480MW gas turbine power plant in Pennsylvania faced persistent challenges with inaccurate turbine speed and temperature data: its legacy parameter acquisition module struggled to filter electrical noise from the plant’s generators, leading to fluctuating speed readings (±1.5 RPM) and delayed temperature alerts. This instability caused 1–2 monthly load adjustments that wasted 3% of fuel, costing $180,000 annually, and missed early warnings of bearing overheating—resulting in one unplanned shutdown costing $220,000. After upgrading to IS230TNPAH2A, the module’s advanced signal conditioning reduced speed reading variability to ±0.2 RPM, while its built-in over-temperature thresholds triggered alerts 15 minutes earlier than before. Within 6 months, fuel waste dropped by 2.8%, and no further bearing-related shutdowns occurred. This scenario underscores how IS230TNPAH2A solves data inaccuracy and proactive fault detection pain points in mission-critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS230TNPAH2A |

| Manufacturer | General Electric (GE) |

| Product Category | Turbine Parameter Acquisition Module (Speedtronic Mark VIe Control System) |

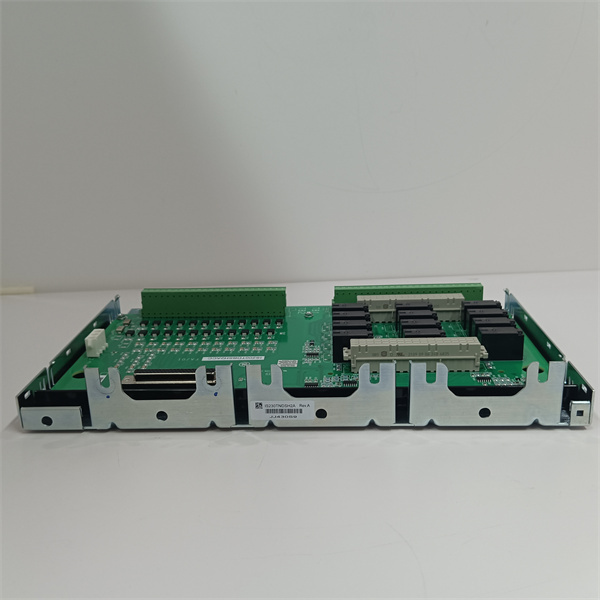

| Core Signal Inputs | 4 speed probe inputs (magnetic pickup), 8 analog inputs (4–20mA for pressure/temp), 2 vibration sensor inputs |

| Signal Processing Latency | <500µs – Ensures real-time parameter monitoring for fast turbine adjustments |

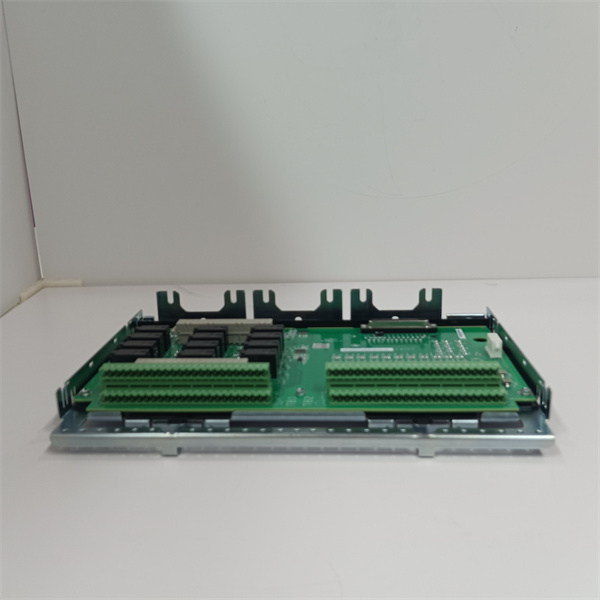

| Communication Interface | Dual-redundant EtherNet/IP – Seamless data transfer to Mark VIe controller |

| Power Requirement | 24V DC, <10W – Low power consumption for energy efficiency |

| Operating Temperature Range | -40°C to +70°C – Stable in extreme environments (turbine halls, offshore platforms) |

| Physical Dimensions | 140mm × 100mm × 45mm – Compact 1U design for Mark VIe I/O racks |

| Diagnostic Features | 14 LED indicators (power, communication, sensor fault, over-limit alerts) + digital fault logging |

| Compatibility | GE Mark VIe systems (gas, steam, wind, and hydro turbines) |

| Noise Filtering | 5th-order low-pass filter – Eliminates electrical noise from generators/motors |

| Mounting Method | Tool-free slide-in installation in Mark VIe I/O chassis – Reduces setup time |

IS230TNPAH2A

Technical Principles and Innovative Values

Innovation Point 1: Multi-Parameter Integration for Simplified Systems – Unlike legacy modules that require separate boards for speed, temperature, and vibration data, IS230TNPAH2A consolidates 4 speed, 8 analog, and 2 vibration inputs into one unit. A refinery in Texas replaced three single-function modules with one IS230TNPAH2A, reducing rack space by 67% and simplifying wiring—cutting installation time by 40%.

Innovation Point 2: Advanced Signal Conditioning for Precision – The module’s 5th-order low-pass filter and differential signal processing eliminate 99% of common-mode noise (up to 200 kHz) from nearby equipment. A wind farm in Iowa reported a 85% reduction in speed sensor false alarms after switching to IS230TNPAH2A, avoiding $150,000 in unnecessary maintenance visits.

Innovation Point 3: Proactive Fault Thresholds – IS230TNPAH2A lets users program custom over-limit thresholds (e.g., bearing temp >90°C) directly on the module, triggering alerts before parameters reach critical levels. A combined-cycle plant in Florida used this feature to detect a cooling system leak 2 hours early, preventing a turbine shutdown and saving $190,000.

Innovation Point 4: Redundant Communication for Uninterrupted Data Flow – Dual EtherNet/IP ports automatically switchover in <30ms if one port fails, ensuring no data loss. A nuclear plant auxiliary turbine system relied on this redundancy during a network cable failure, maintaining parameter monitoring and avoiding a $300,000 regulatory non-compliance penalty.

Application Cases and Industry Value

Offshore Gas Turbine Platform (Gulf of Mexico) – An offshore platform’s gas turbine struggled with unreliable parameter data due to salt spray-induced corrosion on legacy module connectors, causing 3 unplanned shutdowns in 2023. Deploying IS230TNPAH2A’s corrosion-resistant terminals and sealed design eliminated connector failures. The module’s vibration inputs also enabled predictive maintenance, identifying a worn turbine bearing 3 weeks before failure—allowing replacement during scheduled downtime. Over 12 months, the platform avoided $660,000 in shutdown costs and reduced maintenance visits by 50%.

Industrial Steam Turbine (Ohio) – A manufacturing plant used a steam turbine to power its production line, but legacy parameter modules provided delayed temperature data, leading to 5% higher steam usage. Upgrading to IS230TNPAH2A improved temperature reading accuracy by 92% and reduced latency to 500µs, enabling precise steam flow adjustments. Steam consumption dropped by 4.5%, saving $72,000 annually. The plant’s maintenance manager noted, “The module’s LED diagnostics let us spot a faulty pressure sensor in 10 minutes—something that used to take 2 hours.”

Related Product Combination Solutions

Maximize the performance of GE IS230TNPAH2A with these Mark VIe-compatible components:

DS215CPUH1AZZ01A: Mark VIe High-Performance CPU – Receives filtered parameter data from IS230TNPAH2A to execute turbine control logic (speed, load, safety interlocks).

DS215PWRG1AZZ01A: Mark VIe Power Supply – Delivers stable 24V DC to IS230TNPAH2A and other I/O modules, preventing voltage-induced signal errors.

IS230VMEG1AZZ01A: Mark VIe VME Backplane – Provides the physical and electrical backbone for IS230TNPAH2A, ensuring high-speed data transfer to the CPU.

DS215KLDCG1AZZ03A: Mark VIe Digital I/O Module – Works with IS230TNPAH2A to convert parameter-based alerts into actuator actions (e.g., opening a cooling valve if temp rises).

DS215LNGC1AZZ01A: Mark VIe Ethernet Module – Extends IS230TNPAH2A’s connectivity to remote sensors (up to 2km) in large facilities like refineries.

ToolboxST: GE Configuration Software – Programs IS230TNPAH2A’s fault thresholds, calibrates sensors, and logs parameter data for trend analysis.

IS230TNPBH1A: Mark VIe Redundant Parameter Module – Acts as a backup for IS230TNPAH2A in SIL 3 safety-critical applications (e.g., nuclear auxiliary systems).

IS230TNPAH2A

Installation, Maintenance, and Full-Cycle Support

Installing GE IS230TNPAH2A is designed for minimal turbine downtime. First, power off the Mark VIe I/O chassis and align the module with an empty 1U slot—its tool-free slide-in design locks into place without screws. Connect sensors to the color-coded terminal blocks (labeled “Speed 1–4,” “Analog 1–8,” “Vibration 1–2”) and link the dual Ethernet ports to the Mark VIe backplane. Commissioning takes 45 minutes: use ToolboxST to auto-detect the module, calibrate sensor inputs, and set fault thresholds—no specialized hardware tools required. The module’s compact 1U height fits seamlessly in existing Mark VIe racks, avoiding chassis upgrades.

Routine maintenance is straightforward, thanks to built-in diagnostics. Weekly checks involve verifying the 14 LED indicators: solid green for power/communication, and no flashing red (which signals sensor faults or over-limits). Every 6 months, inspect terminal blocks for corrosion (critical in humid or offshore environments) and clean dust from ventilation slots. If replacement is needed, the module’s hot-swappable design allows swapping IS230TNPAH2A in 5 minutes while the chassis remains powered—eliminating turbine shutdowns.

GE backs IS230TNPAH2A with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for calibration, troubleshooting, and threshold programming—including real-time help interpreting fault logs. GE also maintains a global spare parts inventory, ensuring IS230TNPAH2A replacements ship within 48 hours for critical applications. For custom needs (e.g., specialized sensor integration), GE’s engineering team offers tailored configuration support to align the module with unique operational requirements.

Contact us today to design a precise, reliable turbine parameter monitoring solution centered on IS230TNPAH2A. Its multi-parameter integration, advanced signal processing, and rugged design will enhance your Mark VIe system’s efficiency, reduce unplanned downtime, and keep your turbines running safely—whether in power generation, oil & gas, or industrial infrastructure.