Description

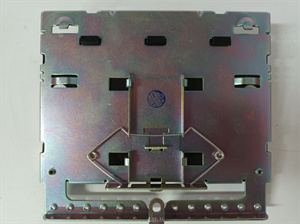

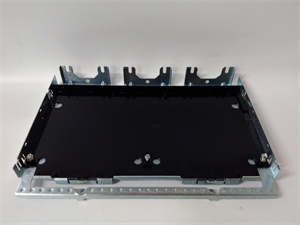

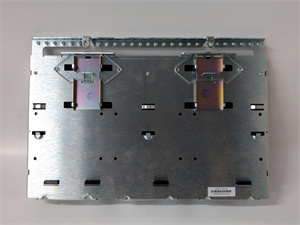

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230TNRLH1B |

| Manufacturer | General Electric |

| Product Type | Relay Output Module |

| Number of Output Channels | 8 |

| Contact Rating | 250 V AC, 5 A; 30 V DC, 5 A |

| Isolation Voltage | 2500 Vrms |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Input Logic | TTL/CMOS Compatible |

| Response Time | < 10 ms |

| Mechanical Life | > 10^7 operations |

| Electrical Life | > 10^5 operations |

| Dimensions | 160 x 100 x 70 mm |

| Weight | 1.2 kg |

IS230TVBAH2A

Main Features and Advantages

High – Capacity Output: The GE IS230TNRLH1B features 8 output channels, allowing it to control multiple devices simultaneously. This high – capacity output makes it suitable for complex industrial applications where a large number of relays need to be managed. It can handle a wide range of loads, from small – scale electrical components to high – power industrial equipment, providing flexibility in system design.

Reliable Isolation: With an isolation voltage of 2500 Vrms, the module offers excellent electrical isolation between the control system and the field devices. This isolation protects the control system from electrical surges and interference, ensuring the safe and reliable operation of the entire system. It also helps prevent electrical faults from spreading, enhancing the overall stability of the industrial automation setup.

Fast Response Time: The IS230TNRLH1B has a response time of less than 10 ms, enabling quick and accurate switching of relays. This fast response is crucial for applications that require real – time control, such as in high – speed manufacturing processes or emergency shutdown systems. It ensures that the system can react promptly to changes in the control signals, minimizing downtime and improving productivity.

Long – Lasting Performance: The module is built to last, with a mechanical life of over 10^7 operations and an electrical life of over 10^5 operations. This long – lasting performance reduces the need for frequent replacements, lowering maintenance costs and improving the overall cost – effectiveness of the industrial automation system. Its ability to withstand a large number of switching cycles makes it a reliable choice for continuous – operation industrial applications.

IS230TVBAH2A

Application Field

Power Generation: In power plants, this module plays a crucial role in controlling the electrical systems. It can be used to switch circuit breakers, control the operation of generators, and manage the distribution of electrical power. In a thermal power plant, the GE IS230TNRLH1B can be used to control the start – up and shut – down of turbines, the operation of cooling systems, and the regulation of power output, contributing to the stable and reliable generation of electricity.

Process Industries: In industries such as chemical, pharmaceutical, and food processing, the IS230TNRLH1B is used to control the flow of fluids, the operation of reactors, and the processing equipment. It can be used to open and close valves, start and stop pumps, and control the temperature and pressure of process vessels. In a chemical plant, it can be used to control the addition of raw materials, the operation of distillation columns, and the release of finished products, ensuring the safe and efficient operation of the chemical processes.

Related Products

GE IS230TNRLH2A: Another relay output module that may offer enhanced features or different channel configurations compared to the GE IS230TNRLH1B. It could be designed for more specialized applications or to meet the evolving needs of industrial automation systems.

GE Mark VIe Control Modules: These are other control modules within the Mark VIe series that work in conjunction with the GE IS230TNRLH1B. They provide the control signals and logic that the relay output module uses to operate the field devices, forming a complete control system for industrial applications.

GE Power Supply Modules for Mark VIe: To ensure the proper operation of the GE IS230TNRLH1B, reliable power supply modules are required. These power supply modules are specifically designed for the Mark VIe series and provide the stable electrical power needed for the module to function effectively.

GE Communication Modules for Mark VIe: These modules facilitate communication between the GE IS230TNRLH1B and other components in the industrial network. They can support various communication protocols, enabling the module to receive control commands and transmit status information, thus integrating the module into a larger, interconnected industrial automation system.

Installation and Maintenance

Maintenance recommendations: Regularly monitor the GE IS230TNRLH1B for any signs of abnormal operation. Check the status of the output relays, ensuring that they are switching correctly and that there are no signs of overheating or arcing. Clean the module periodically to remove dust and debris, especially in dusty industrial environments, as these can affect the electrical performance of the relays. If any relays fail to operate properly, refer to the product manual for troubleshooting steps. In case of component failure, replace the faulty parts with genuine GE – approved components to maintain the integrity and performance of the module.