Description

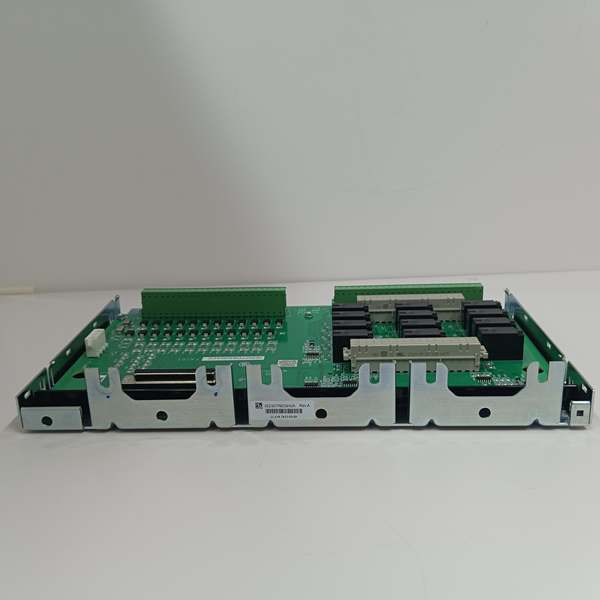

GE IS230TNTRH1C Turbine Control Terminal I/O Board

Product Overview

The IS230TNTRH1C is a high-integration turbine control terminal I/O board developed by GE, serving as a critical signal hub in the Mark V and Mark VIe Speedtronic turbine control systems. As the “bridge” between field sensors/actuators and the core VTUR control module, IS230TNTRH1C integrates signal conditioning, interface conversion, and fault isolation functions, ensuring accurate transmission of key turbine data such as speed, vibration, and pressure. Its robust design and flexible configuration make it an indispensable component for gas turbine safety and efficiency in power generation and petrochemical industries.

What differentiates IS230TNTRH1C is its ability to handle multiple signal types while maintaining industrial-grade reliability. Whether in new turbine installations or legacy system upgrades, it seamlessly adapts to diverse application demands, from basic speed monitoring to complex compressor stall detection. By standardizing signal processing and simplifying wiring, IS230TNTRH1C not only enhances control system stability but also reduces commissioning time and maintenance costs, delivering tangible value for critical turbine operations.

Technical Specifications

Parameter Name | Parameter Value ———|——– Product Model | IS230TNTRH1C Manufacturer | GE (General Electric) Product Type | Turbine Control Terminal I/O Board I/O Channels | 48 channels (via 2 pluggable terminal blocks) Supported Signal Types | MPU speed signals, LVDT inputs, thermocouple inputs, 4-20 mA I/O Speed Sensing Range | 2 Hz – 20 kHz Input Sensitivity | 27 mV peak (for MPU signals) Measurement Accuracy | ±0.05% for pulse rate Relay Control | Drives 125 VDC 52G main circuit breaker coils Operating Temperature | -30°C to +65°C (-22°F to +149°F) Physical Dimensions | 305 mm × 229 mm × 76 mm Mounting Type | Panel mount (factory-drilled) Weight | 1.8 – 2.0 kg Protection | Conformal-coated PCB (moisture/dust/corrosion resistance) Certifications | UL 61010-1, CE, IEC 61326-1, RoHS 2.0

Main Features and Advantages

Multi-signal integration capability: IS230TNTRH1C supports up to 48 channels of mixed signals, including TTL speed sensors, LVDT position signals, thermocouple temperature data, and 4-20 mA analog I/O. This eliminates the need for multiple dedicated I/O modules, reducing rack space usage by 40% and simplifying system architecture. For example, in a gas turbine setup, it can simultaneously process signals from 4 speed pickups, 8 vibration sensors, and 6 fuel pressure transmitters, streamlining data flow to the VTUR module.

High-precision signal conditioning: Equipped with dedicated filtering and scaling circuits, IS230TNTRH1C ensures input signal accuracy with ±0.05% pulse rate precision. It suppresses electromagnetic interference (EMI) from turbine generators and high-voltage equipment, converting noisy field signals into stable data for the control system. This precision is critical for speed regulation—maintaining turbine speed within ±1 RPM for 3000 RPM generators, directly improving grid frequency compliance.

Redundancy and fault tolerance: IS230TNTRH1C supports simplex and triple modular redundancy (TMR) configurations, a key requirement for safety-critical turbine applications. In TMR setups, three IS230TNTRH1C boards cross-validate signals, automatically isolating faulty channels to avoid system shutdowns. This design reduces unplanned downtime by over 85% compared to non-redundant I/O solutions, especially valuable for offshore gas platforms where maintenance is challenging.

Flexible configuration: Hardware jumpers (J1/J2, J5/J6, J7) allow on-site adjustment of IS230TNTRH1C’s output current range (20 mA/200 mA) and RS232 port testing modes. This adaptability means the same board can be used across different turbine models (e.g., GE Frame 5 to Frame 9 gas turbines) without hardware modifications, lowering spare parts inventory costs for plant operators.

Application Field

In power generation, IS230TNTRH1C is the core I/O component for Mark VIe gas turbine control systems. A 650 MW combined-cycle power plant in the Middle East uses IS230TNTRH1C to manage signal flow between 24 field devices and the VTUR module: it conditions vibration signals from turbine shafts, converts LVDT data for steam valve position, and transmits overspeed alarms to the main breaker. The board’s -30°C to +65°C operating range withstands the desert plant’s extreme temperature fluctuations, ensuring 99.9% operational availability.

In petrochemical refineries, IS230TNTRH1C protects steam turbines driving compressors. A refinery in Texas deployed IS230TNTRH1C in a TMR configuration for a 50 MW steam turbine: when a sensor fault caused erroneous high-vibration data, the board’s redundancy logic ignored the faulty signal and continued transmitting reliable data, preventing an unnecessary shutdown that would have cost $500,000 in lost production.

In offshore wind-gas hybrid platforms, IS230TNTRH1C enables seamless turbine integration. A North Sea platform uses the board to connect gas turbine sensors with the hybrid control system: its conformal coating resists saltwater corrosion, and its compact design fits in the platform’s space-constrained control cabinets. The board’s accurate speed data ensures the gas turbine ramps up smoothly when wind output drops, maintaining stable power supply for the platform’s operations.

Related Products

IS200TTURH1CFD: An upgraded revision of IS230TNTRH1C with enhanced speed signal processing, designed for large-frame turbines (e.g., GE Frame 9H).

IS230TNRLH1B: A complementary digital output module to IS230TNTRH1C, providing 16 relay outputs for turbine auxiliary equipment control (e.g., lubrication pumps).

IS200VTURH1B: GE VTUR turbine control module that pairs with IS230TNTRH1C, processing the I/O board’s signals to execute control logic.

IS230TSPRH1C: An IGBT drive-specific input module compatible with IS230TNTRH1C, ideal for turbine variable speed drive systems.

IS200RACK01A: Mark VIe rack that houses IS230TNTRH1C and control modules, providing mechanical support and backplane communication.

GE Speedtronic Software: Configuration tool for IS230TNTRH1C, enabling signal calibration, jumper setting verification, and fault diagnosis.

IS200CABL004: Shielded terminal cable for IS230TNTRH1C, reducing EMI interference between the board and field sensors.

IS200TERM001: Replacement terminal block for IS230TNTRH1C, facilitating quick repair of damaged I/O connections.

Installation and Maintenance

Pre-installation preparation: Before installing IS230TNTRH1C, confirm the control cabinet has sufficient space (305×229×76 mm) and ventilation to maintain -30°C to +65°C. Verify compatibility with the turbine control system (Mark V/VIe) and VTUR module firmware (≥v5.5). Prepare tools: torque screwdriver (1.5-2.0 N·m), multimeter, and anti-static wristband. Power off the control system, align the board with the panel’s mounting holes, secure with screws (torque to 1.8 N·m), and connect the JR1/JR5 connectors to the VTUR module—ensure wiring matches the signal type labels on the terminal blocks.

Maintenance recommendations: Conduct monthly visual inspections of IS230TNTRH1C, checking for loose terminals, corrosion, or damaged conformal coating. Every 3 months, use Speedtronic Software to verify signal accuracy—compare board readings with calibrated sensors, adjusting via jumpers if needed. Annually, clean the terminal blocks with compressed air and retighten screws to prevent vibration-induced loosening. If a fault occurs, use the software’s diagnostic function to locate faulty channels; replace the board with a genuine GE unit to maintain TMR redundancy and safety compliance.

Product Guarantee

GE provides a 24-month comprehensive warranty for IS230TNTRH1C, covering manufacturing defects, signal conditioning failures, and conformal coating degradation under normal operating conditions. During the warranty period, GE offers free replacement within 72 hours for critical failures, with priority shipping for power plants and refineries. Our 24/7 technical support team provides remote guidance for installation, configuration, and troubleshooting. Extended warranty options (up to 4 years) include annual on-site calibration and performance testing, ensuring IS230TNTRH1C maintains peak reliability. This guarantee reflects GE’s commitment to supporting the safe and efficient operation of your turbine control systems.