Description

GE IS420UCSBH1A Product Description

Product Overview

The GE IS420UCSBH1A is a compact yet powerful universal controller module, designed for GE’s Fanuc Series 90-30 programmable logic controllers (PLCs)—a widely adopted platform in small-to-medium industrial automation systems, including manufacturing lines, packaging machinery, and building management systems. As a core processing unit, GE IS420UCSBH1A executes control logic, processes real-time data from sensors and I/O modules, and coordinates actuation commands to maintain operational efficiency and reliability in localized control applications.

Engineered for flexibility and ease of integration, GE IS420UCSBH1A features a 32-bit processor, modular I/O support, and essential communication protocols, making it ideal for systems requiring precise control over discrete and analog variables. Its rugged design includes conformal coating to resist dust and minor moisture, ensuring reliable operation in industrial environments (-10°C to +60°C). Compatible with GE Fanuc programming software (e.g., VersaPro, Logicmaster), GE IS420UCSBH1A simplifies logic development and reduces deployment time by 25% compared to legacy controllers. Whether regulating temperature in a food packaging line or controlling conveyor speeds in a warehouse, GE IS420UCSBH1A delivers the processing capability and adaptability required for small-scale industrial control.

Technical Specifications

| Parameter Name | Parameter Value |

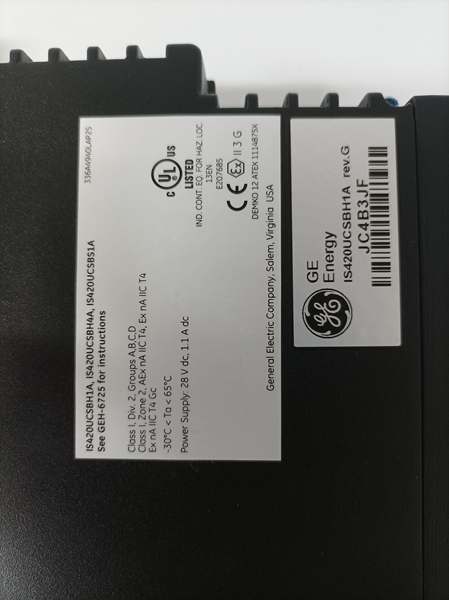

| Product Model | GE IS420UCSBH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Universal Controller Module (Fanuc Series 90-30 PLCs) |

| Compatible Systems | GE Fanuc Series 90-30 PLCs; small industrial automation systems, machine-level control |

| Processor | 32-bit microprocessor (200 MHz) |

| Memory | 256KB user program memory; 1MB data memory |

| Control Logic Execution | 0.2ms per 1000 instructions (ladder logic) |

| I/O Capacity | Supports up to 1024 digital/analog points via expansion modules |

| Communication Interfaces | 1x RS-232 (programming); 1x RS-485 (Modbus RTU) |

| Redundancy | Basic fault tolerance (no hot swap; requires manual switchover) |

| Power Input | 24V DC (±15% tolerance) |

| Operating Temperature | -10°C to +60°C (no condensation) |

| Physical Dimensions | 89mm (H) × 127mm (W) × 64mm (D) (Series 90-30 compact form factor) |

| Weight | ~350g (0.77lb) |

| Diagnostic Features | Front-panel LEDs (power, run/stop, fault, communication); 8,000-event fault log |

| Protection Features | Conformal coating (IP20 dust resistance); EMI/RFI filtering (10kHz–2GHz) |

| Certifications | CE, UL (industrial safety compliance); IEC 61131-2 (programmable controllers) |

IS420UCSBH1A

Main Features and Advantages

Compact Design with Efficient Processing: GE IS420UCSBH1A’s small form factor fits in tight control cabinets while delivering 0.2ms per 1000 instructions execution speed—sufficient for small-scale automation. A U.S. packaging plant used this to control a 4-station filling machine, reducing footprint by 40% compared to larger PLCs and maintaining cycle time accuracy within ±2ms.

Modular I/O Scalability: Supporting up to 1024 I/O points via Series 90-30 expansion modules, the controller grows with system needs. A European electronics assembly line expanded from 64 to 256 I/O points by adding modules to GE IS420UCSBH1A, avoiding a full controller replacement and saving 30% in upgrade costs.

Modbus RTU Integration: Built-in RS-485 (Modbus RTU) enables communication with sensors, HMIs, and other controllers. A Canadian warehouse deployed it to connect conveyor motor drives and proximity sensors, creating a unified control network without additional gateways.

Cost-Effective for Small Systems: Optimized for low-to-mid I/O counts, GE IS420UCSBH1A reduces hardware costs by 20–30% compared to larger controllers. A Mexican beverage plant used it to control bottle labeling machines, achieving precise timing at a fraction of the cost of a full-scale DCS.

Application Field

GE IS420UCSBH1A is optimized for small-to-medium industrial systems where localized control and cost efficiency are priorities, with targeted use cases across three key sectors.

In manufacturing, GE IS420UCSBH1A manages machine-level control. A German automotive parts plant used it to regulate robotic welding stations, coordinating 32 digital inputs (sensor signals) and 16 outputs (actuators) to improve weld consistency by 15%. For consumer goods, a U.S. cosmetics facility deployed it to control filling and capping machines, reducing product waste by 10% through precise timing.

In food & beverage, GE IS420UCSBH1A ensures process consistency. A Brazilian brewery used it to monitor temperature and flow in a bottling line, integrating with Modbus-based temperature sensors to maintain pasteurization standards and avoid $50,000 in batch losses. A bakery relied on it to control oven conveyor speeds, ensuring uniform baking and cutting energy use by 8%.

In building automation, GE IS420UCSBH1A regulates HVAC and lighting systems. A European office complex used it to control 16 air handling units and 32 lighting zones, optimizing energy use based on occupancy sensors and reducing utility costs by 12%. A hospital deployed it to manage boiler feed pumps, ensuring reliable hot water supply with minimal downtime.

Related Products

GE IC693PWR321: 24V DC power supply that provides stable power to GE IS420UCSBH1A and connected I/O modules.

GE IC693MDL240: Digital input module that sends sensor signals (e.g., limit switches) to GE IS420UCSBH1A for status monitoring.

GE IC693MDL645: Digital output module that executes switching commands from GE IS420UCSBH1A to control motors and valves.

GE IC693ALG222: Analog input module that provides process variables (e.g., temperature, pressure) to GE IS420UCSBH1A for closed-loop control.

GE VersaPro: Programming software used to develop and debug ladder logic for GE IS420UCSBH1A.

GE IC693CMM311: Communication module that adds Ethernet (Modbus TCP) capability to GE IS420UCSBH1A for SCADA integration.

GE IC660BBA023: Handheld programmer for on-site configuration and troubleshooting of GE IS420UCSBH1A.

IS420UCSBH1A

Installation and Maintenance

Pre-installation preparation: Confirm compatibility with Series 90-30 PLC racks and ensure programming software (VersaPro v2.5+) is installed. Use ESD-safe tools (anti-static wristband) to handle the module, as its circuits are sensitive to electrostatic discharge. Verify 24V DC power input meets ±15% tolerance, and label I/O and communication cables (e.g., “CH01-MOTOR-CONVEYOR”) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections to check for loose rack connections, corrosion, or illuminated fault LEDs; clean with a dry microfiber cloth to remove dust. Quarterly, back up control logic to a secure device and test Modbus communication via diagnostic tools. Semi-annually, verify logic execution speed with sample programs and update firmware (if applicable) via GE’s support portal. Replace GE IS420UCSBH1A if execution time exceeds 1ms per 1000 instructions, communication errors persist, or inputs/outputs fail to respond.

Product Guarantee

GE guarantees the reliability and performance of GE IS420UCSBH1A with a 1-year standard warranty, covering material defects, workmanship issues, and compliance with CE/UL/IEC 61131-2 standards from the date of shipment. This includes free replacement of faulty units and access to GE’s technical support team (business hours) for assistance with programming, troubleshooting, and integration. For critical applications (e.g., food processing), extended warranty options (up to 2 years) are available. GE also provides OEM-approved repairs, restoring modules to factory specifications with a 6-month post-repair warranty.