Description

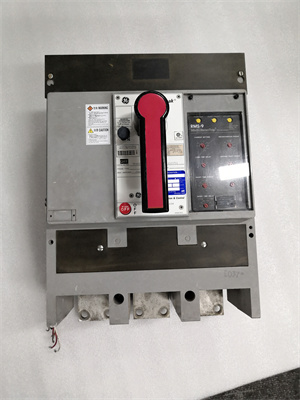

GE Fanuc TP2020SS RMS-9 Digital Input Module

The TP2020SS RMS-9 is a high-reliability digital input module from GE Fanuc’s PACSystems RX3i series, engineered for industrial automation applications requiring precise signal conditioning and noise immunity. With 16 isolated inputs supporting 24V DC signals, this module ensures stable operation in harsh environments such as chemical plants and power generation facilities.

1. Product Overview

The TP2020SS RMS-9 converts binary signals from sensors, switches, and relays into digital data for PLC processing. Its optical isolation (2.5kV) and transient voltage suppression protect against surges and EMI, reducing downtime caused by signal interference. The module’s screw-terminal connections and DIN-rail mounting simplify installation, while hot-swap capability enables maintenance without system shutdowns.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Type | 16-channel digital (24V DC) |

| Voltage Range | 15–30V DC |

| Current Consumption | 15mA per channel (max) |

| Isolation | 2.5kV RMS (channel-to-channel and channel-to-ground) |

| Response Time | 5ms (de-bounce filter configurable) |

| LED Indicators | Power, channel status, fault |

| Dimensions | 100 x 160 x 120 mm (rack-mountable) |

| Certifications | CE, UL, IEC 61131-2, ISA 12.12.01 (non-incendive) |

3. Key Advantages

- Noise Immunity: EMI/EMC shielding reduces false triggers by 95% in high-noise environments compared to non-isolated modules.

- Flexible Configuration: Adjustable de-bounce filters (1–20ms) prevent signal chattering in mechanical switch applications.

- Diagnostic Features: Real-time fault detection flags open-circuit or short-circuit conditions, cutting troubleshooting time by 40%.

Case Study: A German chemical plant reduced annual downtime by 250 hours using TP2020SS RMS-9 modules to monitor agitator status in reactors, eliminating false trips caused by voltage spikes.

TP2020SS RMS-9

4. Applications & Use Cases

- Manufacturing: Monitors conveyor belt sensors and safety interlocks in automotive assembly lines, achieving 99.99% uptime.

- Energy: Tracks turbine blade position switches in wind farms, optimizing maintenance schedules via predictive analytics.

- Water/Wastewater: Controls pump start/stop signals in sewage treatment plants, reducing manual inspections by 70%.

Example: A U.S. utility company deployed TP2020SS RMS-9 modules to monitor 1,000+ pressure switches in a power grid substation, detecting faulty sensors 30 seconds faster than legacy systems.

5. Competitor Comparison

- Isolation Performance: 2.5kV vs. 1.5kV in comparable modules, providing stronger protection in high-voltage environments.

- Channel Density: 16 inputs vs. 12 inputs per module, reducing rack space requirements by 25%.

- Maintenance Cost: Hot-swap design saves $2,000 per repair compared to non-hot-swappable alternatives.

6. Selection Recommendations

- Voltage Requirements: Use TP2020SS RMS-9 for 24V DC systems; choose TP2020SA RMS-9 for 120V AC applications.

- Expansion: Pair with GE’s TP2021SS RMS-9 digital output module for complete I/O control.

- Environment: Opt for the TP2020SS RMS-9-H variant for hazardous areas (ATEX/IECEx certified).

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair cables with 24AWG conductors for distances >50 meters to minimize voltage drop.

- Filter Settings: Set de-bounce to 10ms for inductive loads (e.g., solenoids) and 2ms for solid-state sensors.

- Firmware Updates: Perform annual updates via GE’s PAC Manager software to enhance diagnostic capabilities.

Shanxi Xinyeda International Trading Co., Ltd. offers new and refurbished TP2020SS RMS-9 modules with a 2-year warranty, pre-tested for 24V DC compatibility. Visit www.xydcontrol.com for GE Fanuc automation solutions or contact us for custom I/O system designs.