Description

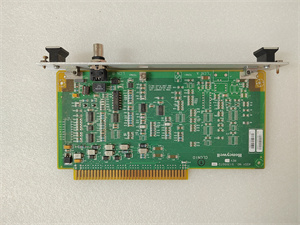

Honeywell 12-SBUS

- •

Model Number: 12-SBUS - •

Manufacturer: Honeywell - •

Product Type: Serial Bus Interface Module - •

Bus Protocol: Honeywell SBUS (proprietary, for C300 controller-remote I/O communication) - •

Number of Ports: 2 (redundant, RS-485 compatible) - •

Redundancy Architecture: Dual-port automatic failover (ring/star topology) - •

Isolation Voltage: 1500VAC (port-to-bus, port-to-ground) - •

Operating Temperature: -40°C to +70°C - •

Power Supply: 24V DC (nominal, 18-30V DC range) from C300 chassis - •

Power Consumption: 3.8W (typical, dual ports active) - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 2 (optional) - •

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits C300 I/O slot) - •

Weight: 0.22kg - •

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) - •

Diagnostics: Bus status (link/activity), port fault, power monitoring, redundancy state Honeywell 12-SBUS