Description

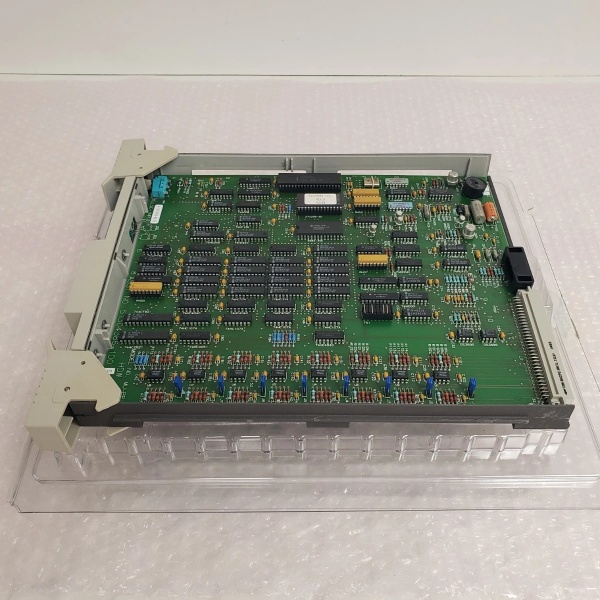

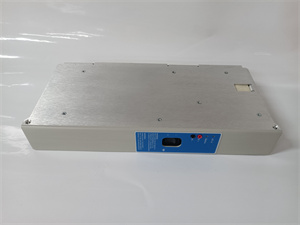

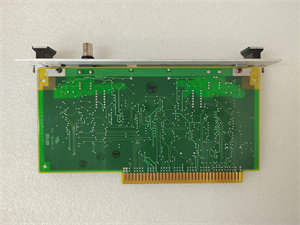

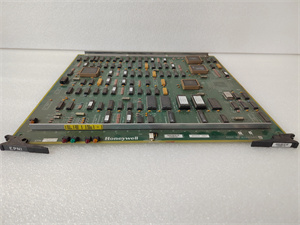

Honeywell 51304386-100

- •

Model Number: 51304386-100 - •

Manufacturer: Honeywell - •

Product Type: Serial Communication Module - •

Communication Protocol: Modbus RTU, Modbus ASCII - •

Interface Type: RS-232 (DB9 female), RS-485 (2-wire/4-wire, terminal block) - •

Number of Channels: 2 (independently configurable) - •

Baud Rate: 9600, 19200, 38400, 57600, 115200 bps (software-selectable) - •

Isolation Voltage: 1500VAC (port-to-bus, port-to-ground) - •

Operating Temperature: -40°C to +70°C - •

Power Supply: 24V DC (nominal, 18-30V DC range) from PKS chassis - •

Power Consumption: 1.8W (typical, both ports active) - •

Humidity Range: 5% to 95% non-condensing - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 2 (optional) - •

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits PKS I/O slot) - •

Weight: 0.18kg - •

Diagnostics: Port status (tx/rx), parity error, framing error, device timeout - •

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) Honeywell 51304386-100