Description

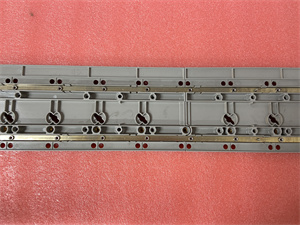

Honeywell 8C-PAOHA

- •

Model Number: 8C-PAOHA - •

Manufacturer: Honeywell - •

Product Type: Analog Output Module - •

Number of Channels: 8 (individually isolated) - •

Output Types: 4-20mA (sink/source, HART 7 supported), 0-10V DC, 0-5V DC - •

Accuracy: ±0.1% of full scale (FS) at 25°C; ±0.2% FS over operating range - •

Resolution: 16-bit (65536 steps) - •

Isolation Voltage: 2500VAC (channel-to-channel, channel-to-bus) - •

Load Impedance: 4-20mA: 0-750Ω; 0-10V: ≥1kΩ - •

Power Supply: 24V DC (nominal, 18-30V DC range) from C300 chassis - •

Power Consumption: 3W (typical, all channels active) - •

Operating Temperature: -40°C to +70°C - •

Humidity Range: 5% to 95% non-condensing - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 2 (optional) - •

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits C300 I/O slot) - •

Weight: 0.2kg - •

Diagnostics: Channel fault (open/short circuit), power status, communication heartbeat, HART device status - •

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) Honeywell 8C-PAOHA