Description

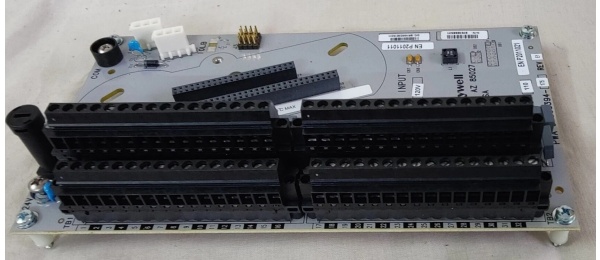

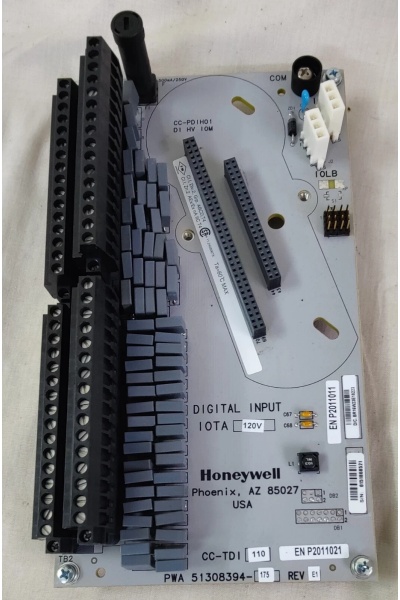

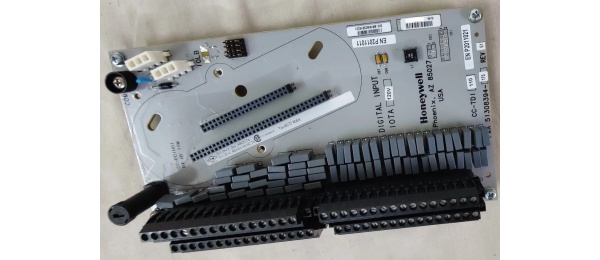

Honeywell CC-TDI220

- •

Model Number: CC-HCN911 - •

Manufacturer: Honeywell - •

Product Type: HART Communication Adapter - •

Protocol Support: HART 7 (primary/secondary master mode) - •

Input Type: 4-20mA with HART (single/dual channel per port) - •

Number of Channels: 4 (individually isolated) - •

Isolation Voltage: 2500VAC (channel-to-bus, channel-to-channel) - •

Accuracy: ±0.1% full scale (FS) for process variables; ±0.5% FS for diagnostic data - •

Resolution: 16-bit (65536 steps) for analog signal processing - •

Power Supply: 24V DC (nominal, 18-30V DC range) from C300 chassis - •

Power Consumption: 2.5W (typical, all channels active) - •

Operating Temperature: -40°C to +70°C - •

Humidity Range: 5% to 95% non-condensing - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 2 (optional) - •

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits C300 I/O slot) - •

Diagnostics: HART device status, loop resistance, communication error, sensor fault, overrange - •

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) Honeywell CC-TDI220