Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – MCAR02

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Industrial control module

|

|

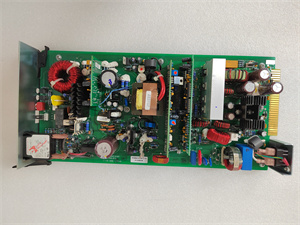

Electrical performance

|

Operating voltage: 220V AC; Output frequency: 50kHz

|

|

Physical size

|

Compact dimensions suitable for various control cabinet setups

|

|

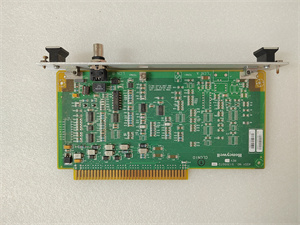

Interface type

|

Standardized interfaces for seamless integration with other components

|

|

Communication protocol

|

Supports multiple industrial communication protocols for effective data transfer

|

|

Environmental requirements

|

Operable in temperatures ranging from – 20 °C to + 60 °C; Resistant to common industrial dust and humidity levels

|

|

Installation method

|

Designed for easy installation, with options for secure mounting in control systems

|

|

Performance indicators

|

High – reliability design for consistent operation; Precise control and monitoring capabilities

|

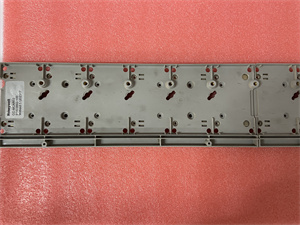

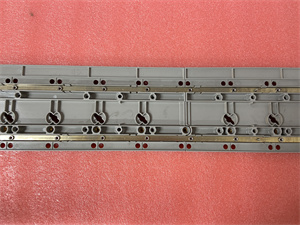

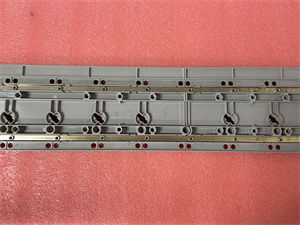

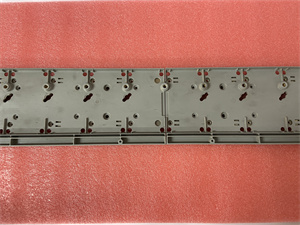

Honeywell CC-MCAR02

Product introduction

The Honeywell CC – MCAR02 is an advanced industrial control module meticulously crafted by Honeywell, a renowned leader in the industrial automation domain. This module is engineered to play a pivotal role in diverse industrial automation applications, ensuring seamless and efficient operations.

It serves as a crucial link in industrial control systems, providing precise control and monitoring capabilities. The CC – MCAR02 is designed to interface with a wide range of industrial devices, collecting data and transmitting control signals. By doing so, it enables real – time monitoring and regulation of industrial processes, which is essential for maintaining high – quality production, optimizing energy consumption, and enhancing overall operational efficiency. As part of Honeywell’s comprehensive suite of industrial control products, the CC – MCAR02 adheres to the company’s high – standards of quality and performance, making it a reliable choice for industries with stringent requirements.

Core advantages and technical highlights

High – reliability design

The CC – MCAR02 features a robust design that ensures consistent performance even under extreme industrial conditions. It is built to withstand temperature fluctuations, vibrations, and electrical interferences commonly found in manufacturing plants, power generation facilities, and other industrial settings. This high – reliability design minimizes the risk of system failures, reducing downtime and maintenance costs, and ensuring continuous and stable operation of industrial processes.

Precise control and monitoring

Equipped with advanced technology, the module offers precise control and monitoring capabilities. It can accurately measure and process various industrial parameters, such as temperature, pressure, and flow rate. The real – time data it provides enables operators to make informed decisions promptly, adjusting process variables to maintain optimal operating conditions. This precision is crucial in industries where even small deviations can lead to significant impacts on product quality or system efficiency.

Multiple protocol support

The CC – MCAR02 supports multiple industrial communication protocols. This versatility allows it to integrate seamlessly with different types of industrial devices and systems, regardless of the communication standards they follow. Whether it’s communicating with sensors, actuators, or other control modules, the module can establish reliable data connections, facilitating smooth data flow and effective control within the industrial automation network.

Durable construction

Constructed using high – quality materials, the CC – MCAR02 is designed to endure the harsh environment of industrial applications. It is resistant to dust, moisture, and chemical corrosion, which are common challenges in industrial settings. This durability not only extends the lifespan of the module but also ensures its performance remains stable over time, providing long – term value to users.

Honeywell CC-MCAR02

Typical application scenarios

Manufacturing industry

In manufacturing plants, the CC – MCAR02 can be used to control and monitor production lines. For example, in an automotive manufacturing plant, it can regulate the speed and operation of robotic arms, ensuring accurate assembly of car parts. It can also monitor the temperature and pressure in industrial furnaces used for heat – treating metal components, maintaining the quality of the manufacturing process. By providing precise control and real – time monitoring, the CC – MCAR02 helps to improve production efficiency, reduce product defects, and enhance overall productivity.

Power generation

In power plants, whether thermal, hydro, or wind, the CC – MCAR02 plays a vital role. In thermal power plants, it can control the combustion process by adjusting the fuel supply and air intake based on real – time temperature and pressure data. In hydroelectric plants, it can monitor the water level and flow rate, and control the opening and closing of valves to optimize power generation. In wind farms, it can regulate the pitch and yaw of wind turbines according to wind speed and direction, ensuring efficient power generation and protecting the turbines from damage.

Oil and gas industry

The CC – MCAR02 is well – suited for the oil and gas industry. It can be used to monitor and control the extraction, transportation, and refining processes. For instance, in oil wells, it can monitor the pressure and flow of oil and gas, and control the operation of pumps and valves to ensure smooth extraction. In refineries, it can regulate the temperature and pressure in distillation columns, optimizing the refining process and ensuring the production of high – quality petroleum products. The module’s ability to operate in harsh environments makes it a reliable choice for the oil and gas industry, where equipment must withstand extreme conditions.

Related model recommendations

CC – MCAR01

Belongs to the same series as the CC – MCAR02. It shares similar basic functions but may have differences in some specifications. For example, it could have a different number of input/output channels or slightly different performance characteristics. It can be considered as an alternative for applications where the specific features of the CC – MCAR02 are not fully required, or for cost – sensitive projects.

FC – MCAR – 02

Another input module from Honeywell. It has a more specific focus on input functions compared to the CC – MCAR02. If the application mainly requires a high – performance input module to collect data from various sensors, the FC – MCAR – 02 might be a more suitable choice. It can work in tandem with the CC – MCAR02 in more complex industrial control systems, with the CC – MCAR02 handling overall control and monitoring tasks while the FC – MCAR – 02 specializes in input data acquisition.

CC – SCMB02

This module from Honeywell may have different functions, such as being more related to signal conditioning or a specific type of control within the industrial automation system. It can be used in combination with the CC – MCAR02 to expand the capabilities of the overall control system. For example, if the CC – MCAR02 is handling the main control tasks, the CC – SCMB02 can be used to pre – process certain signals before they are fed into the CC – MCAR02, enhancing the system’s performance.

CC – TCF901

It may have a different application focus, perhaps related to temperature control or a specific process control function. In industrial processes where temperature – related control is a key aspect, the CC – TCF901 can be used alongside the CC – MCAR02. The CC – MCAR02 can manage the overall system control, while the CC – TCF901 can be dedicated to precise temperature regulation, working together to ensure smooth operation of the industrial process.

CC – TCNT01

Similar to the CC – TCF901, it may have a specialized function. It could be related to time – based control or counting operations in an industrial setting. When the industrial process requires accurate time – stamping of events or counting of certain occurrences, the CC – TCNT01 can be integrated with the CC – MCAR02. The CC – MCAR02 manages the general control tasks, and the CC – TCNT01 handles the time – and count – related operations, complementing each other to meet the complex requirements of the industrial automation system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – MCAR02, carefully assess the installation environment. Ensure that the ambient temperature is within the specified range of – 20 °C to + 60 °C, and the humidity level is within the acceptable limits. The area should be free from excessive dust and strong electromagnetic interference sources. Gather the necessary installation tools, such as screwdrivers and pliers. Thoroughly inspect the module for any signs of damage during transportation. Follow the installation manual provided by Honeywell strictly when making physical connections, ensuring that the module is securely mounted in the control cabinet. When connecting electrical wires, double – check the wiring diagrams to prevent incorrect connections that could lead to malfunctions or safety hazards.

Maintenance suggestions

Regularly inspect the CC – MCAR02 for any signs of physical damage, such as cracks or loose connections. Clean the module periodically using a soft, dry brush to remove dust accumulation, as dust can affect its performance. Monitor the module’s operating temperature, as overheating can cause premature failure. If the temperature exceeds the normal range, check for proper ventilation in the control cabinet. In case of abnormal behavior or error messages, refer to the troubleshooting guide in the product manual. If a component needs replacement, always use genuine Honeywell spare parts to maintain the module’s performance and reliability. Additionally, keep the software and firmware of the module up – to – date by installing the latest updates provided by Honeywell, as these updates often include performance improvements and bug fixes.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the CC – MCAR02. The module comes with a standard warranty that covers defects in materials and workmanship for a specified period. Honeywell’s global network of technical support teams is available around the clock. These teams are highly trained and experienced in dealing with industrial control products. They can provide assistance during installation, commissioning, and troubleshooting. In case of any issues, customers can reach out to the technical support team via multiple channels, such as email, phone, or online chat. Honeywell also offers regular software updates to optimize the module’s performance and keep it compatible with the latest industrial control technologies. If a product failure occurs within the warranty period, Honeywell will promptly provide free repair or replacement services, demonstrating its confidence in the product’s quality and its commitment to customer satisfaction.