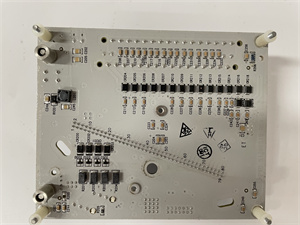

Description

1. Detailed parameter table

**

|

Parameter name

|

Parameter value

|

|

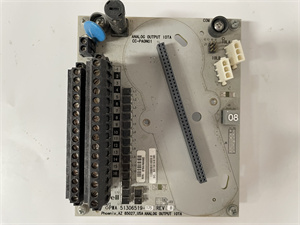

Product model

|

CC – PAON01

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Analog Output Module

|

|

Electrical performance

|

Output signal range: Typically 4 – 20 mA DC or 0 – 10 V DCOutput accuracy: High – precision, with low tolerance levels to ensure accurate control signalsLoad driving capacity: Capable of driving various loads, such as actuators and valves, with sufficient current and voltage output

|

|

Physical size

|

Dimensions: 263×58×28 mmWeight: 4.3 kg

|

|

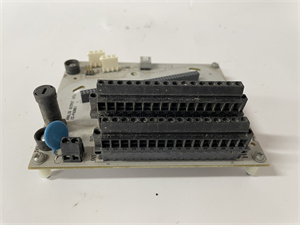

Interface type

|

Interface points designed for seamless connection to field devices and control systems

|

|

Communication protocol

|

Compatible with relevant industrial communication protocols, enabling smooth data transfer within the control system

|

|

Environmental requirements

|

Operating temperature range: – 20°C to 60°CHumidity: 5% – 95% non – condensing, suitable for various industrial environmentsShock and vibration resistance: Can withstand normal industrial vibration and shock levels during operation

|

|

Installation method

|

Designed for easy installation, can be installed in industrial control cabinets, and may support DIN – rail mounting for convenient and space – saving installation

|

|

Performance indicators

|

Number of output channels: Supports multiple channels (e.g., 4 independent channels in some configurations), allowing for multi – tasking control in industrial processesUpdate rate: High – speed updates to ensure responsive control and minimize lag in real – time industrial applications

|

|

Current draw

|

Specific current draw values may vary depending on the operating conditions and load, but designed to operate efficiently within the power supply limits of the control system

|

|

Heat dissipation

|

Incorporates effective heat – dissipation design to ensure stable operation during continuous use, especially in high – density control cabinet environments

|

Honeywell CC-PAON01

2. Product introduction

The Honeywell CC – PAON01 is a high – performance analog output module that plays a pivotal role in industrial automation systems. As part of Honeywell’s comprehensive product portfolio, it is engineered to meet the demanding requirements of modern industrial control applications.

This module is designed to convert digital control signals into proportional analog voltage or current outputs. In industrial settings, it serves as a crucial link between the digital – based control systems, such as programmable logic controllers (PLCs) or distributed control systems (DCS), and the analog – operated field devices. By accurately translating digital commands into analog signals, the CC – PAON01 enables precise control over actuators, valves, and other field equipment. For example, in a chemical plant’s process control system, it can precisely adjust the opening degree of control valves based on the digital control instructions from the DCS, ensuring the correct flow rate of chemical substances. In the context of Honeywell’s Experion PKS (C200, C300) series, the CC – PAON01 is optimized to work in harmony with other components of the system, providing reliable analog output control and contributing to the overall stability and efficiency of the industrial automation process.

3. Core advantages and technical highlights

High – precision output for accurate control

The Honeywell CC – PAON01 offers high – precision analog output. With a narrow tolerance in its output signal range, it can provide extremely accurate control signals. This is essential in industries where precise control is critical, such as pharmaceutical manufacturing. In pharmaceutical production processes, accurate control of flow rates and pressures through valves is required to ensure the quality and consistency of drug products. The high – precision output of the CC – PAON01 enables such accurate control, minimizing variations in the manufacturing process and ensuring product quality.

Multiple channels for multi – tasking control

Featuring multiple output channels (e.g., 4 independent channels in some versions), the CC – PAON01 allows for simultaneous control of multiple field devices. In a large – scale industrial plant, there may be numerous actuators and valves that need to be controlled simultaneously. The multi – channel design of the CC – PAON01 enables it to handle these control tasks efficiently, reducing the need for multiple separate modules and simplifying the overall control system architecture. This not only saves space in the control cabinet but also reduces installation and maintenance costs.

Wide output range and high load – driving capacity

The module has a wide output range, capable of handling diverse process demands. Whether it’s a low – power application or a high – power industrial process, the CC – PAON01 can provide the appropriate output signals. Its high load – driving capacity ensures that it can effectively drive various types of actuators and valves, even those with high – impedance or high – current requirements. In an oil refinery, for instance, large – scale valves with significant operating forces need to be controlled. The CC – PAON01 can supply the necessary power to drive these valves smoothly, ensuring the proper operation of the oil refining process.

Compact design for space – saving installation

Despite its powerful performance, the CC – PAON01 is designed with a compact footprint. Measuring 263×58×28 mm and weighing 4.3 kg, it is easy to install in industrial control cabinets, especially those with limited space. In modern industrial facilities where space is at a premium, this compact design is highly advantageous. It allows for more efficient use of cabinet space, enabling the installation of additional modules or components if needed, without sacrificing the performance of the analog output control function.

High – speed updates for responsive control

The CC – PAON01 supports high – speed updates, which is crucial for real – time industrial control applications. In fast – paced industrial processes, such as high – speed packaging lines or continuous manufacturing processes, quick response to control commands is essential. The high – speed update feature of the CC – PAON01 ensures that the control signals can be adjusted promptly according to the changing process requirements, minimizing lag and improving the overall responsiveness of the control system. This helps to maintain the stability and efficiency of the industrial process, even under dynamic operating conditions.

Honeywell CC-PAON01

4. Typical application scenarios

Chemical industry

In the chemical industry, the Honeywell CC – PAON01 is extensively used. In chemical reaction processes, it controls the flow rate of reactants by precisely adjusting the opening of control valves. For example, in a polymerization reaction, accurate control of the monomer feed rate is crucial to ensure the quality of the polymer product. The CC – PAON01 can convert the digital control signals from the DCS into analog signals to precisely regulate the valve opening, ensuring a stable and consistent reaction process. Additionally, in chemical plants’ wastewater treatment systems, it can control the dosage of various chemical reagents by driving metering pumps, ensuring effective wastewater treatment.

Power generation

In power generation plants, whether thermal, hydro, or wind, the CC – PAON01 plays a vital role. In thermal power plants, it controls the steam turbine’s speed by adjusting the opening of the steam control valves. By accurately converting digital control commands into analog signals, it can precisely regulate the steam flow rate, ensuring stable power generation. In wind farms, the module can control the pitch angle of wind turbine blades. Based on the wind speed and direction data received by the control system, the CC – PAON01 sends analog signals to the blade pitch actuators, optimizing the power generation efficiency of the wind turbines.

Manufacturing industry

In manufacturing plants, especially those with automated production lines, the CC – PAON01 is widely applied. In an automotive assembly line, it can control the movement of robotic arms. By providing accurate analog control signals, it enables the robotic arms to move precisely to pick and place parts, ensuring the smooth operation of the assembly process. In a food and beverage production line, it can control the filling volume of packaging machines. The CC – PAON01 adjusts the flow rate of the filling valves according to the digital control instructions, ensuring consistent filling levels in each package and maintaining product quality.

5. Related model recommendations

CC – PAOH01

This is also an analog output module from Honeywell. It may support the Hart protocol, which can be used for status and configuration of field devices. While the CC – PAON01 focuses on basic analog output functionality, the CC – PAOH01 adds the Hart communication feature, making it suitable for applications where communication with Hart – enabled field devices is required, such as in more complex industrial control systems with intelligent sensors and actuators.

CC – PAOX01

Another analog output module, it might have different output characteristics or channel configurations compared to the CC – PAON01. For example, it could have a different number of output channels or a different output signal range. In applications where the specific requirements for the number of output channels or the output signal range do not match those of the CC – PAON01, the CC – PAOX01 could be a more suitable choice.

CC – TAON01

This module may be related to the CC – PAON01 in terms of being part of the same series or having complementary functions. It could potentially be an analog output module with different features, such as a different form factor or different levels of isolation. In some industrial control systems where specific installation requirements or isolation needs are crucial, the CC – TAON01 might be a better fit than the CC – PAON01.

CC – PDOB01

As a digital output module, it has a different function from the analog output CC – PAON01. In industrial control systems that require both digital and analog output capabilities, the CC – PDOB01 can be used for digital – based control tasks, such as controlling the on – off state of relays, while the CC – PAON01 handles the analog output requirements for more precise control of devices like valves and motors.

CC – PDIL01

A digital input module, it complements the CC – PAON01 in a complete industrial control system. The CC – PDIL01 is responsible for collecting digital input signals from field devices, such as sensor switch signals, and sending them to the control system. The control system can then process these signals and use the CC – PAON01 to output analog control signals based on the processed data, enabling comprehensive control of industrial processes.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – PAON01, select a suitable location in the control cabinet. Ensure that the ambient temperature is within the specified range of – 20°C to 60°C and the humidity is between 5% – 95% non – condensing. Prepare the necessary installation tools, such as screwdrivers for DIN – rail mounting if applicable. Carefully inspect the module for any signs of damage during transportation. When making electrical connections, follow the wiring diagrams provided in the product manual precisely. Connect the power supply correctly, ensuring that the voltage matches the module’s requirements. All connections to field devices should be made securely to prevent loose connections that could lead to signal interference or incorrect output.

Maintenance suggestions

Regularly check the physical condition of the CC – PAON01 for any signs of wear, corrosion, or loose connections. Dust accumulation can affect the module’s performance, so clean it periodically using a soft brush or compressed air. Monitor the output signals regularly to ensure they are within the expected range. In case of any abnormal output, such as incorrect voltage or current values, refer to the troubleshooting guide in the product manual. If a component needs replacement, use only genuine Honeywell spare parts to maintain the module’s performance and reliability. Additionally, keep the control cabinet environment clean and well – ventilated to aid in the module’s heat dissipation and long – term operation.

7. Service and guarantee commitment

Honeywell stands firmly behind the Honeywell CC – PAON01 with a comprehensive service and guarantee commitment. The module comes with a standard warranty, typically covering defects in materials and workmanship for a specified period. Honeywell’s global network of technical support teams is available around the clock. Whether it’s assistance during the installation phase, help with commissioning the module, or troubleshooting complex issues, these experts are readily accessible. The company also provides regular software updates and product enhancements to ensure that the CC – PAON01 continues to perform optimally in evolving industrial environments. This commitment to service and quality assurance reflects Honeywell’s confidence in the reliability and durability of the CC – PAON01, giving customers peace of mind when integrating it into their critical industrial control systems.