Description

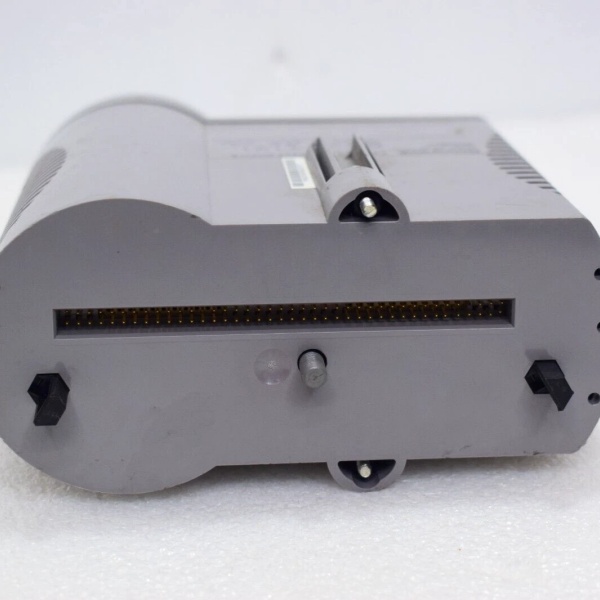

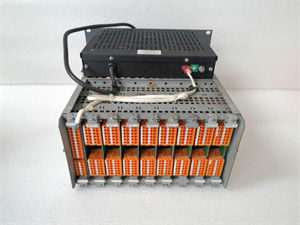

Honeywell CC-PFB801

- •

Model Number: CC-PFB801 - •

Manufacturer: Honeywell - •

Product Type: Profibus DP Communication Module - •

Communication Protocol: Profibus DP V1 (slave mode) - •

Data Rate: 9.6 kbps to 12 Mbps (configurable) - •

Interface Type: 9-pin D-sub (RS-485 compatible) - •

Supported Devices: Smart transmitters, VFDs, valve positioners, remote I/O - •

Power Supply: 24V DC (nominal, 18-30V DC range) from C300 chassis - •

Operating Temperature: -40°C to +70°C - •

Certifications: SIL 2 (IEC 61508), CE, UL, PROFIBUS International Certified - •

Redundancy: Dual-port design for ring/star topology redundancy - •

Dimensions: 25mm x 128mm x 115mm (fits C300 I/O slot) - •

Weight: 0.18kg - •

Diagnostics: Communication status, device fault, cable break, sync error Honeywell CC-PFB801