Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | CC – TAID01 |

| Manufacturer | Honeywell |

| Product category | Analog Input Module |

| Input channels | 8 differential or 16 single – ended |

| Input range (voltage) | – 10V to + 10V |

| Input range (current) | 0mA to 20mA; 4mA to 20mA |

| Resolution | 16 bits |

| Input impedance (voltage) | > 1MΩ |

| Input impedance (current) | 250Ω |

| Accuracy | ±0.1% of full scale |

| Update rate | Configurable, up to 1000 samples per second |

| Operating temperature | – 20°C to + 60°C |

| Power supply | 24V DC, typical power consumption 3W |

| Dimensions (L×W×H) | [Specify accurate dimensions if available] |

| Weight | [Specify weight if available] |

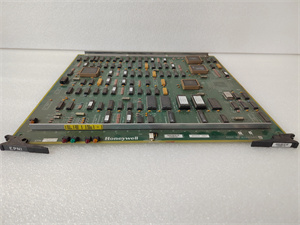

Honeywell CC-TAID01

Product introduction

Honeywell, a renowned name in industrial automation, presents the Honeywell CC – TAID01 analog input module as an essential component of its advanced control systems. This module is an integral part of the Experion Process Knowledge System (PKS), designed to meet the complex requirements of industrial applications.

The Honeywell CC – TAID01 serves as a crucial interface between the field – based analog sensors and the digital control systems. Its primary function is to accurately convert analog signals, such as those from temperature, pressure, and flow sensors, into digital data that can be processed by Programmable Logic Controllers (PLCs), Distributed Control Systems (DCSs), or other control devices. With multiple input channels, it enables the simultaneous acquisition of numerous analog signals, providing a comprehensive view of the industrial process. This module plays a pivotal role in ensuring that control systems have access to real – time, reliable data, which is essential for making informed decisions and maintaining efficient operations in industrial environments.

Core advantages and technical highlights

High – accuracy data acquisition

The CC – TAID01 employs a high – precision A/D converter, allowing for extremely accurate data collection. With an accuracy of ±0.1% of full scale, it ensures that the digital representation of analog signals closely matches the actual values. This level of precision is vital in applications where even minor deviations in measurement can lead to significant consequences, such as in chemical processes where precise control of reactant flow rates is necessary for product quality and safety.

Robust and reliable design

Built with industrial – grade components, the module is engineered to withstand harsh industrial conditions. It can operate within a wide temperature range of – 20°C to + 60°C, making it suitable for use in various environments, from cold storage facilities to hot manufacturing plants. The module has also been rigorously tested and verified, guaranteeing long – term reliability and minimizing the risk of unexpected failures that could disrupt industrial operations.

Flexible input configuration

This module offers great flexibility in handling different types of analog inputs. It supports both voltage and current inputs, with multiple input ranges available. This means it can interface with a wide variety of sensors and transmitters commonly used in industrial settings. Whether it’s a voltage – output temperature sensor or a current – output pressure transmitter, the CC – TAID01 can be configured to accurately capture the signal, providing versatility for system integrators and engineers.

Advanced diagnostic capabilities

Equipped with built – in diagnostic features, the CC – TAID01 can quickly identify and report potential issues. It can detect problems such as sensor malfunctions, wiring faults, or abnormal signal levels. This not only helps in rapid troubleshooting but also enables predictive maintenance, allowing operators to address issues before they cause system failures. By providing detailed diagnostic information, the module contributes to increased system uptime and reduced maintenance costs.

Honeywell CC-TAID01

Typical application scenarios

Power generation

In power plants, the Honeywell CC – TAID01 is used to monitor and control critical parameters. For example, it can collect analog signals from temperature sensors in boilers to ensure that the combustion process is operating at optimal temperatures. By accurately measuring the temperature, the control system can adjust the fuel – air ratio, improving efficiency and reducing emissions. Additionally, it can monitor the pressure of steam turbines using pressure sensors, ensuring safe and efficient operation. Any deviation from normal operating parameters can be quickly detected, allowing for timely corrective actions.

Oil and gas

In the oil and gas industry, the module plays a vital role in various processes. During oil refining, it can be used to measure the flow rates of different oil fractions using flow sensors. Precise flow rate measurement is crucial for maintaining the proper balance in the refining process, ensuring high – quality product output. In gas pipelines, the CC – TAID01 can monitor the pressure and temperature of the gas, helping to detect leaks or other anomalies. By providing real – time data, it enables operators to respond promptly and prevent potential disasters.

Manufacturing

In manufacturing plants, especially in the automotive and electronics sectors, the CC – TAID01 is used for quality control and process optimization. In automotive assembly lines, it can measure the torque applied by robotic screwdrivers using torque sensors. Consistent torque application is essential for ensuring the proper fastening of components, which affects the safety and durability of the final product. In electronics manufacturing, it can monitor the temperature and humidity levels in cleanrooms, as these factors can significantly impact the performance of electronic components during production.

Related model recommendations

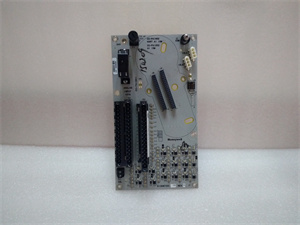

CC – TAIX11

It is a related analog input module, likely with some differences in functionality or specifications. It might have a different number of input channels or enhanced features for specific applications. For example, it could be designed for applications that require higher – density input connections or more advanced signal conditioning capabilities compared to the CC – TAID01.

CC – PAIX02

Another analog input module, but it may be optimized for different types of analog signals or have a different accuracy level. It could be more suitable for applications where the input signals have a different range or where a different level of precision is required. For instance, in applications that deal with very low – level analog signals, the CC – PAIX02 might offer better sensitivity.

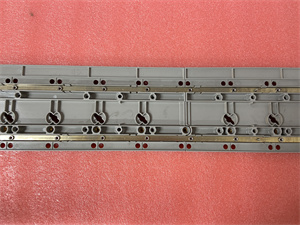

CC – TAIN01

This is an analog input 底板. It serves as a base for connecting multiple analog input modules, including potentially the CC – TAID01. It provides the necessary electrical connections and power distribution for a group of input modules, allowing for efficient integration and expansion of the analog input system in larger industrial control setups.

8C – TAIMA1

A low – level (RTD/TC) input module. It is designed specifically for handling low – level signals from Resistance Temperature Detectors (RTDs) and Thermocouples. While the CC – TAID01 can handle a broader range of analog inputs, the 8C – TAIMA1 is more specialized for these types of temperature – sensing devices, offering better accuracy and signal conditioning for such applications.

CC – PDIL01

Although it is a digital input module, it often works in tandem with the CC – TAID01 in industrial control systems. The CC – PDIL01 receives digital input signals from sensors and switches, while the CC – TAID01 handles analog signals. Together, they provide a comprehensive data – acquisition solution for control systems, enabling the monitoring and control of both digital and analog aspects of industrial processes.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TAID01, ensure that the installation environment meets the specified temperature and humidity requirements. Gather the necessary installation tools, such as screwdrivers and wire strippers. Disconnect all power sources in the control system to avoid electrical hazards. Check the module for any visible damage. Mount the module securely in the control cabinet, following the provided installation guidelines. Make sure to properly connect the power supply, input signals, and communication cables. Ensure that the wiring is neat and organized to prevent signal interference.

Maintenance suggestions

Regularly inspect the CC – TAID01 for physical damage, such as cracks in the casing or loose connections. Check the input signals using appropriate testing equipment to ensure they are within the expected range. If any input channels show abnormal behavior, first check the wiring and connections. If the problem persists, use the module’s diagnostic features to identify the issue. When replacing parts, always use genuine Honeywell components to maintain the module’s performance and reliability. Periodically clean the module to remove dust and debris, as these can affect its performance over time. Also, keep the software and firmware of the module up – to – date to benefit from the latest features and bug fixes.

Service and guarantee commitment

Honeywell stands behind the Honeywell CC – TAID01 with a comprehensive service and guarantee package. The product typically comes with a standard warranty, during which any manufacturing defects will be promptly addressed. Honeywell’s global technical support team is available around the clock to assist customers. Whether it’s an issue with installation, configuration, or troubleshooting, customers can expect professional and timely assistance. The company also provides regular software updates and product enhancements to keep the CC – TAID01 at the forefront of performance. This commitment reflects Honeywell’s confidence in the quality of the module and its dedication to ensuring long – term customer satisfaction in the industrial automation domain.