Description

Detailed parameter table

| Parameter name | Parameter value |

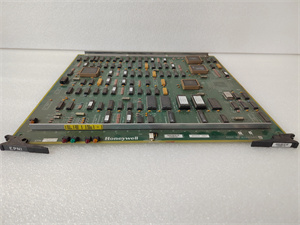

| Product model | EG1033AC01 |

| Manufacturer | Honeywell |

| Product category | Industrial process controller |

| Control modes | PID, ON/OFF, Manual, Auto-tune |

| Input types | 3 universal inputs (thermocouple, RTD, 4-20 mA, 0-10 V) |

| Output types | 3 outputs (2 relay, 1 analog: 4-20 mA/0-10 V) |

| Display | 4.3-inch color LCD with touchscreen |

| Communication interfaces | RS-485 (Modbus RTU), Ethernet (Modbus TCP/IP) |

| Operating voltage | 100-240 V AC ±10% |

| Power consumption | Max 15 W |

| Operating temperature | -10°C to +55°C (14°F to 131°F) |

| Dimensions | 144 mm x 144 mm x 100 mm (5.7 in x 5.7 in x 3.9 in) |

| Weight | 0.8 kg (1.8 lbs) |

| Certifications | CE, UL, CSA, ATEX |

| Mounting type | Panel mount (flush or surface) |

Honeywell EG1033AC01

Product introduction

The Honeywell EG1033AC01 is a versatile industrial process controller engineered to regulate temperature, pressure, flow, and other critical process variables in manufacturing and industrial environments. As part of Honeywell’s Experion series, this controller combines intuitive operation with robust control capabilities, making it suitable for applications ranging from small batch processes to integrated production lines.

Honeywell EG1033AC01 stands out for its flexible input/output configuration and advanced control algorithms, enabling precise regulation of diverse processes. Its 4.3-inch color touchscreen simplifies setup and monitoring, while support for industry-standard communication protocols ensures seamless integration with SCADA systems and PLCs. Whether deployed in food processing, chemical production, or pharmaceutical manufacturing, Honeywell EG1033AC01 delivers consistent performance, helping to maintain product quality, reduce waste, and optimize energy usage.

Core advantages and technical highlights

Multi-variable control capability: EG1033AC01 features 3 universal inputs that accommodate thermocouples (J, K, T, etc.), RTDs (Pt100), and analog signals (4-20 mA, 0-10 V), allowing it to monitor multiple process variables simultaneously. For example, in a chemical reactor, it can track temperature, pressure, and flow rate—adjusting heating elements, pressure valves, and pumps via its 3 outputs to maintain optimal conditions. This eliminates the need for multiple single-loop controllers, simplifying system architecture.

Advanced PID with auto-tune: The controller’s PID algorithm includes adaptive tuning and auto-tune functionality, which automatically adjusts proportional, integral, and derivative parameters based on process dynamics. This is particularly valuable for batch processes with varying loads, such as plastic extrusion, where temperature setpoints change frequently. Auto-tune reduces setup time by up to 70% compared to manual tuning, ensuring stable control even for operators with limited expertise.

Intuitive user interface: The 4.3-inch color LCD touchscreen of EG1033AC01 provides clear visualizations of process trends, setpoints, and alarms. Operators can quickly switch between control modes, adjust parameters, and acknowledge alarms with a few taps. The screen supports multiple languages and customizable display layouts, adapting to user preferences and regional requirements. In dusty or wet environments, the touchscreen works with gloves, ensuring operability in harsh conditions.

Seamless system integration: Equipped with RS-485 and Ethernet ports, EG1033AC01 communicates via Modbus RTU and TCP/IP, enabling easy integration with Honeywell’s Experion PKS or third-party SCADA systems. This allows for centralized monitoring and control of multiple EG1033AC01 units across a facility. For example, in a food processing plant, a central SCADA can coordinate temperature controllers for ovens, chillers, and pasteurizers, ensuring consistent product quality across production lines.

Typical application scenarios

Food and beverage processing plants utilize EG1033AC01 to control pasteurization processes, where precise temperature regulation (±0.5°C) is critical for food safety. The controller monitors product temperature via a thermocouple input, adjusting heating elements through a relay output to maintain the required pasteurization temperature (e.g., 72°C for milk). Its auto-tune function adapts to variations in product flow rate, ensuring compliance with regulatory standards while minimizing energy use.

Plastic manufacturing facilities deploy EG1033AC01 in injection molding machines to regulate barrel and mold temperatures. The controller’s 3 inputs track temperatures at different zones of the barrel, while outputs adjust heater bands to maintain setpoints. Its PID algorithm compensates for heat loss during mold opening/closing, reducing cycle times and improving part consistency. Integration with the plant’s MES via Ethernet allows for recipe management and production data logging.

Pharmaceutical production uses EG1033AC01 in tablet coating processes, where it controls both pan temperature and airflow. The controller’s analog output adjusts the heating valve, while relay outputs manage blower motors and spray pumps. Its data logging capability records temperature and pressure profiles, providing documentation for FDA compliance audits. The touchscreen interface allows operators to select pre-programmed recipes, ensuring consistent coating quality across batches.

Honeywell EG1033AC01

Related model recommendations

Honeywell EC1033AC01: A sister model with similar functionality but optimized for lower-power applications, serving as a cost-effective alternative to EG1033AC01 for simple temperature control.

Honeywell UDC3500: Advanced process controller with expanded I/O, suitable for large-scale systems requiring coordination with EG1033AC01 in complex industrial processes.

Honeywell STT750: Temperature transmitter that pairs with EG1033AC01, providing accurate RTD signals for applications requiring high-precision measurements.

Honeywell XC1000: PLC that integrates with EG1033AC01 to handle sequential control tasks, such as batch sequencing, alongside the controller’s regulatory control.

Honeywell PM400: Power monitor that communicates with EG1033AC01 via Modbus, enabling energy usage tracking for processes under the controller’s management.

Honeywell T6861H: Remote temperature sensor designed for use with EG1033AC01 in hard-to-reach areas, extending the controller’s monitoring range.

Installation, commissioning and maintenance instructions

Installation preparation: Mount EG1033AC01 in a panel cutout of 138 mm x 138 mm, ensuring a secure fit with the provided flange. Connect to a 100-240 V AC power supply with a 0.5 A fuse, using a dedicated circuit to avoid interference. Route input/output wiring through separate conduit from power cables to minimize noise. For hazardous areas, install the controller in an ATEX-approved enclosure. Label all connections clearly (e.g., “Reactor Temp,” “Heater Output”) for easy identification.

Commissioning and maintenance: Power on EG1033AC01 and configure input types, output assignments, and control parameters via the touchscreen. Use the auto-tune function during initial setup, running a full process cycle to optimize PID settings. Verify communication with the SCADA system by checking data transmission and alarm forwarding. Perform monthly visual inspections to ensure the screen is clean and connections are tight. Calibrate inputs quarterly using certified standards (e.g., a precision temperature bath for thermocouples). Update firmware annually via Ethernet to access new features and improvements.

Service and guarantee commitment

Honeywell EG1033AC01 is backed by a 3-year warranty covering manufacturing defects and ensuring compliance with published performance specifications. Honeywell’s industrial control support team provides 24/7 technical assistance, with a 4-hour response time for critical issues, including remote troubleshooting and configuration guidance.

Customers receive access to online training modules and user manuals for EG1033AC01, supporting efficient setup and operation. Extended warranty options up to 5 years include annual calibration checks and priority service. Honeywell maintains regional stock of EG1033AC01 units, enabling next-day delivery for replacements. All repairs use genuine components, with post-repair testing to validate accuracy and reliability, ensuring the controller meets industrial process requirements throughout its service life.