Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FC-RUSIO-3224 |

| Manufacturer | Honeywell |

| Product category | Redundant universal safety I/O module |

| Number of channels | 32 (16 inputs, 16 outputs, fully isolated) |

| Input type | Configurable (24 V DC PNP/NPN, dry contact) |

| Output type | Relay (changeover), 250 V AC / 30 V DC |

| Maximum switching current | 5 A per output channel (resistive load) |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Response time | Input: ≤1 ms; Output: ≤5 ms |

| Isolation rating | 3 kV AC (channel to channel, channel to backplane) |

| Operating voltage | 24 V DC ±15% (redundant power inputs) |

| Power consumption | Max 25 W (including redundancy) |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 160 mm x 120 mm x 90 mm (6.30 in x 4.72 in x 3.54 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Safety Manager, Experion PKS, FC-SDI-1624, FC-TSDO-0824 |

| Mounting type | DIN rail mounting (35 mm) with redundant backplane support |

| Certification | IEC 61508, ATEX, IECEx, UL 508, TÜV SÜD |

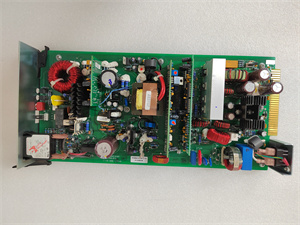

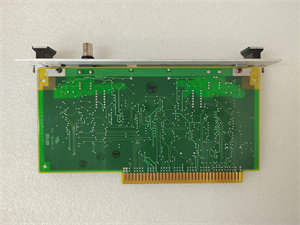

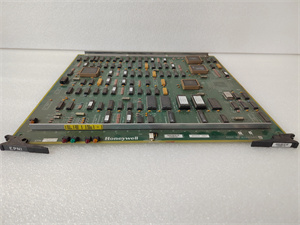

HONEYWELL FC-RUSIO-3224

Product introduction

The FC-RUSIO-3224 is a high-integrity redundant universal safety I/O module from Honeywell, engineered to serve as a robust foundation for mission-critical safety systems in industrial environments. As a flagship component of Honeywell’s advanced safety portfolio, this module combines 16 configurable safety inputs and 16 safety relay outputs in a single, redundant design, delivering uncompromising reliability for applications where downtime or failure could have catastrophic consequences.

FC-RUSIO-3224 is uniquely designed to bridge safety sensors and actuators with control systems, offering both input data acquisition and output control capabilities in a redundant architecture. Its SIL 3 certification ensures it meets the highest safety integrity requirements, making it ideal for use in high-risk industries such as oil and gas, chemical processing, and nuclear power. Whether integrated into Honeywell’s Safety Manager for complex emergency shutdown (ESD) logic or paired with Experion PKS for centralized monitoring, FC-RUSIO-3224 provides seamless redundancy, ensuring continuous operation even in the event of component failures—forming the backbone of safety-critical infrastructure.

Core advantages and technical highlights

Full redundancy architecture: FC-RUSIO-3224 features dual processors, redundant power inputs, and mirrored I/O channels, eliminating single points of failure. In the event of a primary processor fault, the module automatically switches to the redundant processor with zero downtime, ensuring safety loops remain active. This redundancy extends to communication paths, with dual Ethernet ports supporting seamless failover in networked systems. For example, in a refinery’s crude distillation unit, a processor failure won’t interrupt the monitoring of pressure switches or the actuation of emergency shutdown valves.

SIL 3 safety integrity: Certified to SIL 3 per IEC 61508, FC-RUSIO-3224 exceeds the requirements of most industrial safety applications, with 99.99% availability and 100% fault coverage via advanced diagnostics. Its design incorporates 2oo2D (two-out-of-two with diagnostics) voting logic, ensuring spurious trips are minimized while genuine hazards are never missed. This level of integrity is critical for applications like offshore platform safety systems, where a single failure could lead to environmental disasters or loss of life.

Universal I/O flexibility: With 16 inputs configurable as 24 V DC PNP, NPN, or dry contact, and 16 relay outputs rated for 5 A, FC-RUSIO-3224 eliminates the need for separate input and output modules. Inputs can connect to diverse devices such as emergency stops, light curtains, and pressure switches, while outputs control shutdown valves, alarms, and contactors. This versatility simplifies system design in large-scale facilities, reducing cabinet space and wiring complexity by up to 30% compared to discrete modules.

Enhanced diagnostic capabilities: FC-RUSIO-3224 offers comprehensive self-diagnostics, including real-time monitoring of relay contact wear, channel isolation integrity, and power supply health. Diagnostic data is transmitted via HART and Ethernet, enabling predictive maintenance—for example, alerting technicians to replace a relay before contact failure. The module also provides detailed event logs with time-stamping (±1 ms accuracy), supporting root-cause analysis in the event of safety actions or faults.

Typical application scenarios

In offshore oil platforms, FC-RUSIO-3224 serves as the primary safety I/O module for wellhead ESD systems. Its 16 inputs monitor high-pressure switches, gas detectors, and emergency stop buttons, while 16 outputs control subsea shutdown valves, fire suppression systems, and evacuation alarms. The module’s redundancy ensures continuous operation during harsh weather conditions or component failures, while its SIL 3 rating guarantees reliable response to hazards like blowouts or gas leaks. Integration with Safety Manager allows for complex logic, such as shutting down multiple wellheads sequentially to prevent cascading failures.

Nuclear power plants utilize FC-RUSIO-3224 in reactor protection systems, where it monitors neutron flux sensors, temperature limit switches, and pressure transducers (via inputs) and controls reactor trip solenoids, coolant pumps, and isolation valves (via outputs). Its redundant design and SIL 3 certification are critical for meeting regulatory requirements, ensuring the reactor can be safely shut down even if a module component fails. The module’s wide temperature range (-40°C to +70°C) withstands the harsh conditions of containment buildings.

Chemical processing facilities deploy FC-RUSIO-3224 in batch reactor safety loops, where it integrates with FC-SDI-1624 for expanded input capacity. The module monitors rupture disc sensors, toxic gas detectors, and 搅拌器过载 switches (inputs) while actuating emergency relief valves, nitrogen purge systems, and area alarms (outputs). Its fast response time (≤1 ms for inputs, ≤5 ms for outputs) ensures rapid action during exothermic reaction runaways, preventing explosions or toxic releases.

HONEYWELL FC-RUSIO-3224

Related model recommendations

FC-RUSIO-1624: A 16-channel variant (8 inputs, 8 outputs) of FC-RUSIO-3224, ideal for smaller-scale redundant systems such as pharmaceutical batch reactors or LNG storage facilities.

Safety Manager R: Honeywell’s redundant safety controller that pairs with FC-RUSIO-3224 to execute SIL 3 logic, supporting complex interlocks across multiple modules.

FC-SDI-1624: Safety digital input module that expands FC-RUSIO-3224’s input capacity in large systems, with seamless integration via redundant backplanes.

FC-TSDO-0824: Complementary safety output module for applications requiring additional relay channels beyond FC-RUSIO-3224’s 16 outputs.

FC-PS24-5A-R: Redundant 24 V DC power supply optimized for FC-RUSIO-3224, featuring dual inputs and automatic failover to maintain uninterrupted operation.

Redundant Backplane BP-R: DIN rail-mounted backplane that connects multiple FC-RUSIO-3224 modules, enabling synchronized data exchange and redundancy across I/O racks.

Experion PKS Redundant Server: High-availability SCADA server that integrates with FC-RUSIO-3224 to provide real-time visualization of safety I/O status in redundant control rooms.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-RUSIO-3224, ensure the DIN rail and redundant backplane are mounted in a climate-controlled, explosion-proof enclosure with ambient temperature between -40°C and +70°C. Use a torque wrench set to 1.2 Nm to secure the module, ensuring proper alignment with the backplane connectors. Connect dual 24 V DC power supplies (each fused at 3A) to the redundant power inputs, with separate grounding for each supply to prevent common-mode faults. Use 0.75 mm² shielded twisted-pair cables for inputs and 1.5 mm² cables for outputs, grounding shields at both ends for noise immunity. Label all channels clearly, noting input/output type and connected device.

Maintenance suggestions: For FC-RUSIO-3224, perform weekly checks of status LEDs to verify redundant processor synchronization and power supply health. Use Honeywell’s Safety Builder software monthly to run full diagnostic scans, including relay contact resistance testing and isolation integrity checks. Calibrate response times annually using an oscilloscope, ensuring input delays remain ≤1 ms and output actuation ≤5 ms. Replace relays proactively at 80% of their rated lifespan (100,000 operations) to prevent unexpected failures. Coordinate maintenance with redundant module pairs, performing work on one module at a time to keep safety loops active. Always use Honeywell-certified spares to maintain SIL 3 integrity, and back up configuration settings to dual secure servers.

Service and guarantee commitment

FC-RUSIO-3224 is backed by Honeywell’s industry-leading 7-year warranty, covering manufacturing defects and ensuring compliance with SIL 3 and hazardous area certifications under normal operating conditions. Honeywell’s global critical systems support team provides 24/7 technical assistance with a 2-hour response time for critical issues, including on-site support within 24 hours for offshore or remote locations.

We offer comprehensive commissioning services, including redundancy validation, SIL 3 loop testing, and integration with Safety Manager/Experion PKS, performed by TÜV-certified safety engineers. Extended warranty options (up to 10 years) include annual preventive maintenance, firmware updates, and priority access to replacement parts. In the event of a fault, Honeywell maintains global stock of FC-RUSIO-3224 modules, enabling 4-hour delivery to major industrial hubs. All repairs use genuine components, with post-repair testing to ensure compliance with original SIL 3 specifications. This commitment reflects Honeywell’s dedication to safety excellence and customer operational confidence in the most critical environments.