Description

Detailed parameter table

| Parameter name | Parameter value |

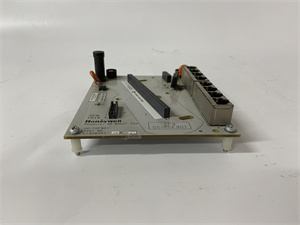

| Product model | FC-SCNT01 (Part Number: 51454926-176) |

| Manufacturer | Honeywell |

| Product category | Safety controller module |

| Processing capacity | Supports up to 10,000 safety logic elements |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Redundancy | 2oo2 (two-out-of-two) architecture |

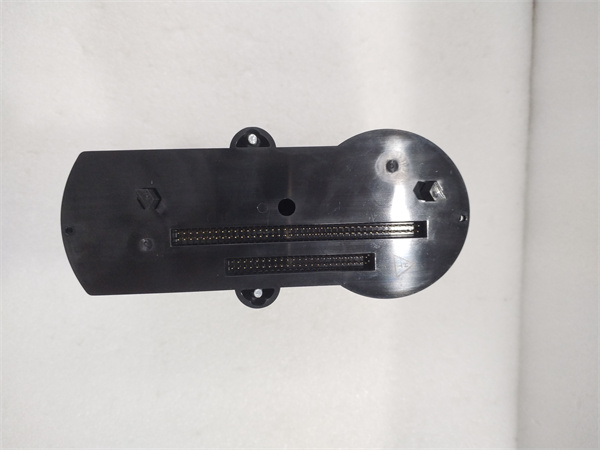

| Communication interfaces | Dual Ethernet (10/100 Mbps), RS-485, PROFIBUS DP |

| Supported protocols | Modbus TCP/IP, PROFIBUS, Honeywell Safety Protocol |

| Memory | 1 GB RAM, 8 GB flash storage |

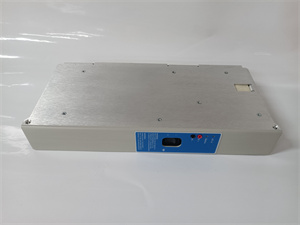

| Operating voltage | 24 V DC ±10% (redundant power inputs) |

| Power consumption | Max 30 W (per redundant unit) |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 170 mm x 130 mm x 100 mm (6.69 in x 5.12 in x 3.94 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell FC-RPB2N12, FC-RUSIO-3224, Safety Manager |

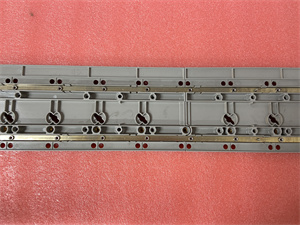

| Mounting type | DIN rail mounting (35 mm) with backplane connectivity |

| Certification | IEC 61508, EN 61511, ATEX, IECEx, UL 508 |

Honeywell FC-SCNT01 51454926-176

Product introduction

The FC-SCNT01 (51454926-176) is a high-integrity safety controller module from Honeywell, designed to serve as the core of safety instrumented systems (SIS) in industrial environments. As a critical component of Honeywell’s safety automation portfolio, this module combines advanced processing capabilities with a redundant architecture to execute safety logic, monitor hazardous conditions, and trigger protective actions in high-risk applications.

FC-SCNT01 is engineered to meet SIL 3 requirements, making it suitable for scenarios where failure to act could result in catastrophic consequences, such as in oil refineries, chemical plants, and power generation facilities. Its 2oo2 redundancy ensures no single point of failure, while seamless integration with field controllers like the FC-RPB2N12 and I/O modules such as FC-RUSIO-3224 enables end-to-end safety loop management. Whether deployed as part of a standalone SIS or integrated with Honeywell’s Experion PKS, FC-SCNT01 provides reliable, deterministic control—forming the brain of safety-critical operations.

Core advantages and technical highlights

SIL 3 safety integrity: FC-SCNT01 achieves SIL 3 certification per IEC 61508, the highest level for most industrial applications, with a fault tolerance of 1 (single fault tolerant) and a probability of failure on demand (PFD) below 1e-4. Its 2oo2 architecture uses dual processors that continuously cross-verify results, ensuring spurious trips are minimized while genuine hazards trigger immediate action. This level of integrity is critical for applications like reactor overpressure protection, where a missed trip could lead to explosions.

Redundant design: The module features redundant processors, power inputs, and communication ports, eliminating single points of failure. In the event of a primary processor fault, the system automatically switches to the secondary processor with zero downtime, maintaining safety loop functionality. Redundant Ethernet and PROFIBUS interfaces ensure uninterrupted communication with I/O modules and human-machine interfaces (HMIs), even during network disruptions.

High processing capacity: With support for up to 10,000 safety logic elements, FC-SCNT01 handles complex safety sequences, such as emergency shutdown (ESD) logic for multi-zone facilities or interlock systems for entire production lines. Its 1 GB RAM and 8 GB flash storage enable rapid execution of logic, with a scan time as low as 10 ms—ensuring timely responses to hazardous conditions.

Seamless system integration: FC-SCNT01 integrates seamlessly with Honeywell’s FC-RPB2N12 field controller, enabling coordination between safety and standard control systems. It communicates with I/O modules like FC-RUSIO-3224 via PROFIBUS and Modbus, allowing centralized management of safety inputs (e.g., emergency stops) and outputs (e.g., shutdown valves). This interoperability simplifies system design and reduces integration costs.

Typical application scenarios

In petrochemical refineries, FC-SCNT01 serves as the core of the ESD system, monitoring pressure, temperature, and gas detection signals from FC-RUSIO-3224 modules. When hazardous conditions are detected (e.g., a gas leak exceeding 50% LEL), it executes pre-programmed logic to shut down affected units, close isolation valves, and activate fire suppression systems—all within milliseconds. Its redundancy ensures the ESD system remains operational even if a processor or communication link fails, preventing escalation of incidents.

Nuclear power plants utilize FC-SCNT01 in reactor protection systems, where it processes data from neutron flux sensors and coolant pressure transducers. The module’s SIL 3 rating ensures it meets regulatory requirements for safety, while its fast scan time (10 ms) enables rapid trip decisions to prevent core damage. Integration with FC-RPB2N12 allows coordination between safety shutdowns and non-safety control functions, such as reducing turbine load during abnormal conditions.

Chemical batch processing facilities deploy FC-SCNT01 to manage reactor safety interlocks. It monitors variables like pH, temperature, and agitator speed via analog inputs, triggering emergency cooling or feed shutdowns if thresholds are exceeded. The module’s ability to handle complex logic allows for sequential shutdowns (e.g., first stopping feed pumps, then activating isolation valves), minimizing material waste and ensuring operator safety.

Honeywell FC-SCNT01 51454926-176

Related model recommendations

FC-RUSIO-3224: Redundant universal safety I/O module that connects to FC-SCNT01, providing 32 channels of inputs and outputs for safety sensors and actuators.

FC-RPB2N12: Field controller that pairs with FC-SCNT01 to bridge safety and standard control systems, enabling data sharing between SIS and process control networks.

Safety Manager HMI: Honeywell’s human-machine interface for FC-SCNT01, allowing operators to monitor safety loop status, modify logic (with authorization), and view diagnostic data.

FC-PS24-5A-R: Redundant 24 V DC power supply optimized for FC-SCNT01, ensuring uninterrupted operation during power fluctuations or supply failures.

TÜV Certified Logic Editor: Software tool for programming FC-SCNT01’s safety logic, featuring drag-and-drop functionality and automatic SIL verification to simplify compliance.

Installation, commissioning and maintenance instructions

Installation preparation: Mount FC-SCNT01 on a 35 mm DIN rail in a climate-controlled, explosion-proof enclosure (if in hazardous areas). Ensure the backplane is securely connected to redundant power supplies (24 V DC, fused at 2A) and communication networks (Ethernet and PROFIBUS). Use shielded cables for all connections, grounding shields at both ends to minimize EMI. Label redundant units (Primary/Secondary) and communication ports for easy identification.

Commissioning: Configure the module using Honeywell’s safety logic editor, defining input/output mappings, safety logic, and communication parameters. Verify redundancy by simulating a primary processor fault and confirming automatic failover to the secondary unit. Test safety loops by injecting fault signals (e.g., open circuit on an emergency stop) and ensuring the module triggers the correct output response. Validate SIL 3 compliance with a third-party audit, documenting all test results for regulatory records.

Maintenance suggestions: Perform weekly checks of status LEDs to verify redundant synchronization and power health. Use diagnostic software monthly to run self-tests, checking for memory errors, communication faults, and processor health. Calibrate communication interfaces annually to ensure data integrity with I/O modules. Replace redundant units sequentially during maintenance (never both at once) to keep safety loops active. Back up logic configurations to a secure server, and update firmware only with Honeywell-approved versions to maintain SIL certification.

Service and guarantee commitment

FC-SCNT01 (51454926-176) is backed by Honeywell’s 5-year warranty, covering manufacturing defects and ensuring compliance with SIL 3 specifications under normal operating conditions. Honeywell’s global safety support team provides 24/7 technical assistance, with a 2-hour response time for critical issues and on-site support within 48 hours for unresolved problems.

We offer commissioning services by TÜV-certified engineers, including SIL verification, logic validation, and integration with existing systems. Extended warranty options (up to 10 years) include annual preventive maintenance, firmware updates, and priority access to replacement parts. In the event of a fault, Honeywell maintains regional stock of FC-SCNT01 modules, enabling next-day delivery to minimize SIS downtime. All repairs use genuine components, with post-repair testing to ensure compliance with original SIL 3 standards. This commitment reflects Honeywell’s dedication to safety excellence and customer operational confidence.