Description

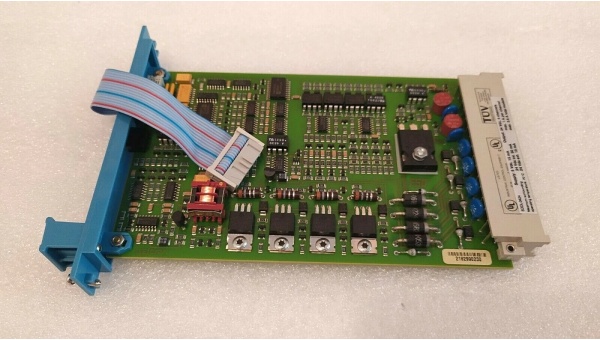

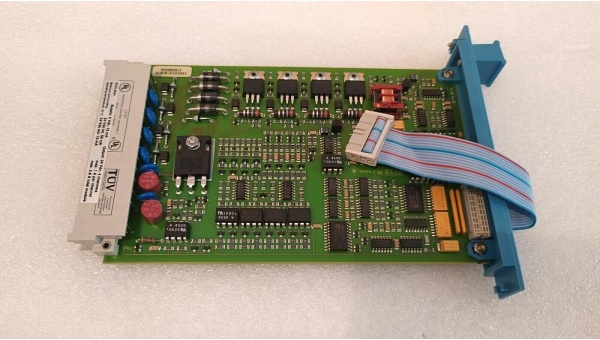

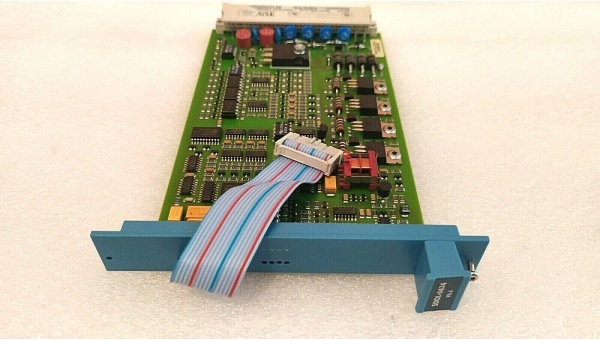

Honeywell FC-SDOL-0424

- •

Model Number: FC-SDOL-0424 - •

Manufacturer: Honeywell - •

Product Type: Safe Digital Output Module (SIS) - •

Channels: 4 (individually isolated) - •

Output Type: Dry Contact (relay, 5A @ 250V AC), Wet Contact (24 VDC, 1A sink/source) - •

Isolation Voltage: 1,500 VAC (channel-to-channel, channel-to-bus) - •

SIL Certification: SIL 3 (Hardware Fault Tolerance ≥ 1, PFDavg < 1E-9) - •

Diagnostic Coverage: > 99% (per IEC 61508) - •

Response Time: < 20 ms (typical, from controller command to output activation) - •

HART Support: Yes (HART 7, for diagnostic data transmission) - •

Operating Voltage: 24 VDC ±10% (from C300 chassis) - •

Power Consumption: 3 W (max) - •

Operating Temperature: -40°C to +70°C - •

Humidity Tolerance: 5–95% non-condensing - •

Certifications: ATEX, IECEx, cFMus, UL, CE - •

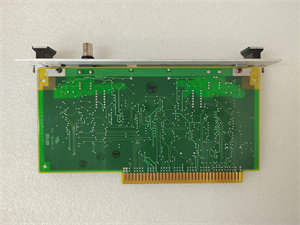

Connection: Removable screw terminal block (0.2–2.5 mm² wire) - •

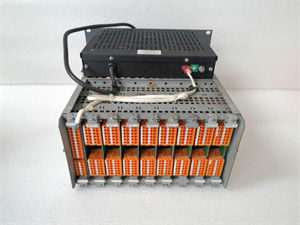

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) Honeywell FC-SDOL-0424

1. Ultra-High Safety Integrity (SIL 3 Certified)

2. Advanced Diagnostics for Proactive Maintenance

- •

Coil failure: Alerts when a solenoid valve coil is open/short circuit. - •

Contact weld: Detects welded relay contacts (a critical failure mode in emergency stops). - •

Leakage current: Measures current flow to ensure reliable dry-contact operation. Predictive analytics in Honeywell’s Safety Manager software use this data to forecast end-of-life for connected devices (e.g., a valve actuator nearing failure), allowing maintenance teams to schedule replacements during planned downtime—reducing unplanned outages by up to 30%.