Description

Detailed parameter table

| Parameter name | Parameter value |

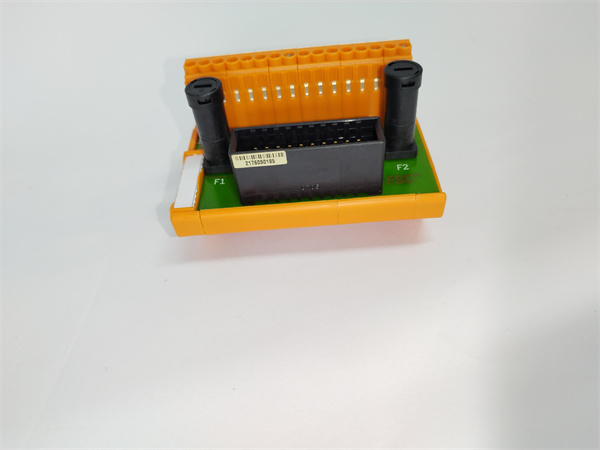

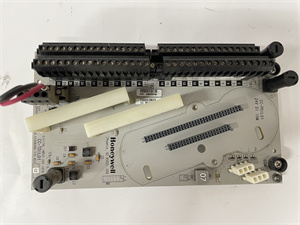

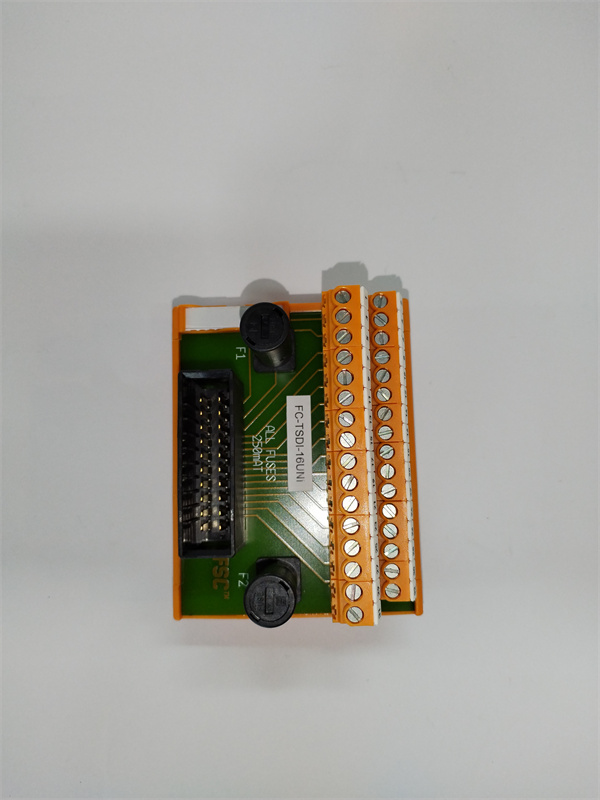

| Product model | FC-TSDI-16UNI |

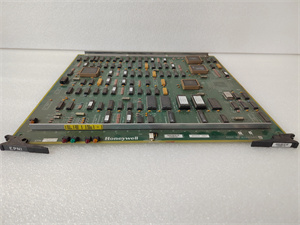

| Manufacturer | Honeywell |

| Product category | Universal safety digital input module |

| Number of channels | 16 (isolated) |

| Input type | Configurable (24 V DC PNP/NPN, dry contact) |

| Input voltage range | 18-30 V DC (for active inputs) |

| Response time | ≤2 ms (configurable: 1-100 ms) |

| Isolation rating | 3 kV AC (channel to channel, channel to backplane) |

| Safety integrity level | SIL 2 (per IEC 61508) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 10 W |

| Operating temperature range | -40°C to +70°C (-40°F to +158°F) |

| Dimensions (LxWxH) | 135 mm x 105 mm x 70 mm (5.31 in x 4.13 in x 2.76 in) |

| Protection rating | IP20 |

| Compatibility | Honeywell Safety Manager, Experion PKS, FC-TSDO-0824 |

| Mounting type | DIN rail mounting (35 mm) |

| Certification | IEC 61508, ATEX, IECEx, UL 508 |

Honeywell FC-TSDI-16UNI

Product introduction

The FC-TSDI-16UNI is a highly versatile universal safety digital input module from Honeywell, designed to serve as a critical data acquisition layer in industrial safety systems. As a key component of Honeywell’s safety I/O ecosystem, this module excels in capturing status signals from a wide range of safety devices, converting them into actionable data for safety controllers and monitoring systems.

FC-TSDI-16UNI features 16 isolated channels with universal input capabilities, supporting both active (24 V DC PNP/NPN) and passive (dry contact) devices—eliminating the need for separate modules for different sensor types. Its SIL 2 certification ensures reliability in safety-critical loops, making it ideal for monitoring emergency stops, interlock switches, light curtains, and pressure/temperature switches. Whether integrated with Honeywell’s Safety Manager for emergency shutdown logic or with Experion PKS for centralized status tracking, FC-TSDI-16UNI provides accurate, real-time input data, forming the foundation of robust safety decision-making in industries such as oil and gas, chemicals, and manufacturing.

Core advantages and technical highlights

Universal input flexibility: FC-TSDI-16UNI stands out for its ability to configure each channel independently as 24 V DC PNP, 24 V DC NPN, or dry contact input. This versatility allows seamless integration with diverse safety devices—from PNP-based light curtains in automotive plants to NPN emergency stops in chemical facilities, or dry contact pressure switches in oil refineries. Engineers can program input types via software, reducing inventory complexity and simplifying retrofits where mixed sensor types are present.

SIL 2 safety integrity: Certified to SIL 2 per IEC 61508, FC-TSDI-16UNI incorporates redundant signal processing, 99% fault coverage via built-in diagnostics, and continuous monitoring of channel health. It detects faults such as open circuits, short circuits, and overvoltage conditions, triggering immediate alerts to prevent false or missed signals. This level of reliability is critical in applications like machine guard interlocks, where a failed input could mask a breached safety barrier.

Rapid response with adjustability: With a base response time of ≤2 ms, FC-TSDI-16UNI ensures fast detection of safety events—essential for high-speed machinery where milliseconds matter. For noisy environments, response time is configurable up to 100 ms to filter interference, balancing speed and signal stability. This adaptability makes it suitable for both precision applications (e.g., robotic cell interlocks) and harsh settings (e.g., vibrating industrial pumps).

Enhanced channel isolation: Each of the 16 channels features 3 kV AC isolation from other channels and the backplane, preventing cross-talk and protecting against voltage transients. This isolation ensures a fault in one channel (e.g., a shorted emergency stop) does not affect others, maintaining system integrity in distributed safety loops. For example, in a refinery with multiple wellhead interlocks, a fault in one well’s sensor won’t disable monitoring of others.

Typical application scenarios

In automotive manufacturing plants, FC-TSDI-16UNI monitors safety devices in robotic welding cells. Its universal inputs connect to PNP light curtains (detecting operator entry), NPN door interlocks (verifying guard closure), and dry contact emergency pulls (manual shutdown triggers). The module’s fast response time (<2 ms) ensures the robot stops immediately upon a breach, while integration with Safety Manager coordinates shutdowns across multiple cells. Configurable inputs simplify upgrades when replacing legacy sensors with newer types.

Chemical processing facilities utilize FC-TSDI-16UNI to monitor pressure switch contacts and temperature limit switches in reactor systems. Dry contact inputs track pressure thresholds, while 24 V DC NPN inputs monitor high-temperature alarms. The module’s 3 kV isolation prevents interference from nearby motors, ensuring accurate detection of hazardous conditions. When paired with FC-TSDO-0824, it forms a closed loop: input signals trigger output relays to shut down feed pumps, preventing overpressure incidents.

Oil and gas platforms deploy FC-TSDI-16UNI in wellhead safety systems, connecting to emergency shutdown (ESD) buttons, flame detector contacts, and valve position switches. Its wide operating temperature range (-40°C to +70°C) withstands offshore environmental extremes, while universal inputs accommodate both new NPN sensors and legacy dry contact devices during platform upgrades. HART communication with Experion PKS provides real-time status updates, enabling operators to verify sensor health remotely.

Honeywell FC-TSDI-16UNI

Related model recommendations

FC-TSDI-32UNI: A 32-channel variant of FC-TSDI-16UNI, ideal for large-scale systems like refineries or manufacturing plants requiring extensive safety monitoring.

FC-TSDO-0824: Honeywell’s safety digital output module that pairs with FC-TSDI-16UNI to form complete safety loops, executing shutdowns based on input signals.

FC-QPP-0001: Safety controller that processes data from FC-TSDI-16UNI, enabling complex logic sequences and extending safety capabilities to SIL 3 in redundant setups.

SensaGuard 440G: Honeywell’s safety light curtain, optimized for use with FC-TSDI-16UNI, providing PNP outputs for seamless integration in machine safety applications.

FC-PS24-2A: Redundant 24 V DC power supply designed to support FC-TSDI-16UNI, ensuring uninterrupted operation during power fluctuations.

Safety Manager: Honeywell’s safety instrumented system that integrates FC-TSDI-16UNI data to execute emergency shutdowns and alarm sequences.

FC-TSHART-1620M: Analog input module that complements FC-TSDI-16UNI, adding 4-20 mA monitoring capabilities for mixed-signal safety systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing FC-TSDI-16UNI, ensure the DIN rail is mounted in a dust-free, vibration-free enclosure (explosion-proof if in hazardous areas) with ambient temperature between -40°C and +70°C. Use a torque wrench set to 1.0 Nm to secure the module. Verify the 24 V DC power supply is isolated, fused (1.5A), and grounded to minimize noise. Use 0.75 mm² shielded twisted-pair cables for input connections, grounding the shield at the module end. Route signal cables separately from power lines, and label each channel with the connected device (e.g., “ES-101 Curtain”) for troubleshooting.

Maintenance suggestions: For FC-TSDI-16UNI, perform monthly visual inspections to check for loose terminals or corrosion. Test input channels quarterly using a signal generator or test switch, verifying response time and correct status reporting in Safety Manager. Use Honeywell’s Safety Builder software monthly to run diagnostic scans, checking for channel faults or communication errors. Calibrate response time annually using an oscilloscope, ensuring it meets application requirements (≤2 ms for high-speed loops). Replace with Honeywell-certified spares only to maintain SIL 2 integrity, and back up configuration settings to a secure device.

Service and guarantee commitment

FC-TSDI-16UNI is backed by Honeywell’s 5-year warranty, covering manufacturing defects and ensuring compliance with SIL 2 and hazardous area certifications under normal operating conditions. Honeywell’s global safety support team provides 24/7 technical assistance, with certified engineers available to assist with configuration, loop testing, and integration—critical issues are addressed within 4 hours.

We offer on-site commissioning services, including input type verification, response time testing, and integration with Safety Manager or Experion PKS. Extended warranty options (up to 7 years) include annual preventive maintenance, firmware updates, and priority access to replacement parts. In the event of a fault, Honeywell maintains regional stock of FC-TSDI-16UNI modules, enabling next-day delivery to minimize safety system downtime. All repairs use genuine components, ensuring the module retains its original isolation ratings, response time, and safety certifications. This commitment reflects Honeywell’s dedication to industrial safety and customer operational confidence.