Description

Detailed parameter table

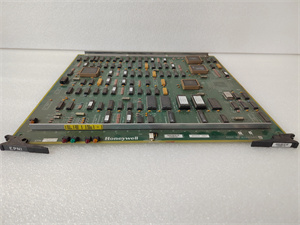

| Parameter name | Parameter value |

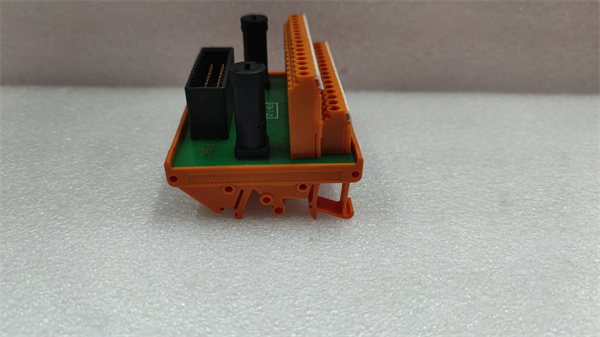

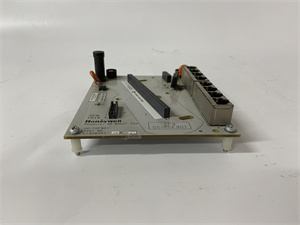

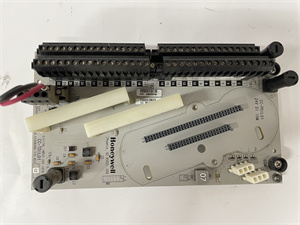

| Product model | FTA-T-21 |

| Manufacturer | Honeywell |

| Product category | Advanced safety digital I/O module |

| Input voltage | 24 VDC (digital input mode); 120/240 VAC (selectable) |

| Output voltage | 30 VDC/250 VAC (Overvoltage Category III) |

| Maximum output current | 3 A per channel |

| Channel configuration | 21 configurable channels (16 outputs + 5 inputs) |

| Operating temperature | -30°C to +70°C |

| Storage temperature | -40°C to +125°C |

| Dimensions | 112 mm x 105 mm x 62 mm |

| Weight | 0.32 kg |

| Certifications | IEC 61508 (SIL 3), ATEX, IECEx, UL 1998 |

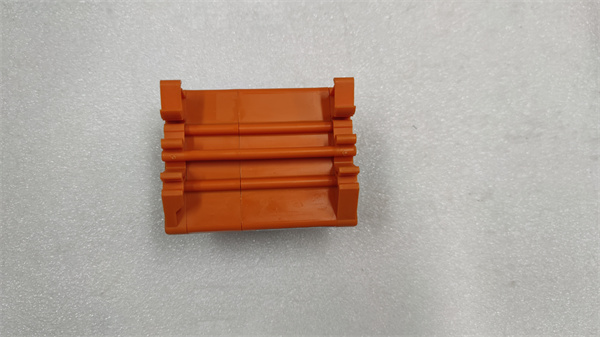

| Mounting type | DIN rail mounting (35 mm) with backplane interface |

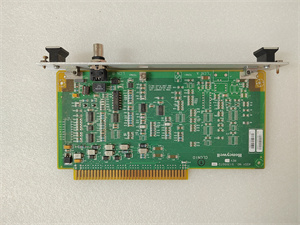

Honeywell FTA-T-21

Product introduction

The Honeywell FTA-T-21 is an advanced safety digital I/O module engineered for high-performance industrial automation systems requiring enhanced channel density and safety integrity. As an upgraded variant in Honeywell’s FTA series, this module builds on the capabilities of its predecessors with an expanded 21-channel configuration, combining 16 safety outputs and 5 inputs to handle complex safety loops in critical applications.

Honeywell FTA-T-21 integrates seamlessly into safety instrumented systems (SIS) and emergency shutdown systems (ESD), providing fail-safe operation that ensures controlled transitions to safe states during fault conditions. Its robust design supports both low-voltage (24 VDC) and high-voltage (120/240 VAC) inputs, making it suitable for diverse industrial environments from chemical plants to power generation facilities. Whether deployed in new installations or retrofits, Honeywell FTA-T-21 delivers the reliability and flexibility needed to enhance system safety and operational efficiency.

Core advantages and technical highlights

Enhanced channel density: FTA-T-21 offers 21 configurable channels (16 outputs + 5 inputs), providing 50% more I/O capacity than comparable modules like the FTA-T-14. This higher density reduces panel space requirements by allowing more safety functions to be consolidated into a single module, ideal for complex systems such as multi-zone emergency shutdown networks in refineries. Each channel operates independently, ensuring a fault in one loop doesn’t affect others—a critical feature for maintaining system integrity.

SIL 3 safety certification: Certified to IEC 61508 SIL 3, FTA-T-21 meets the most stringent safety requirements for high-risk applications. It incorporates 2oo3 (two-out-of-three) voting logic, advanced diagnostic coverage (>99%), and redundant signal paths to minimize spurious trips while ensuring rapid response to genuine hazards. This level of integrity makes it suitable for protecting critical assets like offshore oil platforms and nuclear power plant auxiliary systems.

Broad voltage compatibility: Unlike modules limited to low-voltage operation, FTA-T-21 supports both 24 VDC and 120/240 VAC inputs, eliminating the need for external signal converters when interfacing with legacy high-voltage devices such as motor control centers or older emergency stop circuits. This versatility simplifies integration in brownfield sites where mixed voltage systems are common, reducing installation time and costs.

Extended environmental range: With an operating temperature range of -30°C to +70°C, FTA-T-21 outperforms standard modules in extreme environments. It withstands humidity up to 95% (non-condensing) and vibration up to 5g, making it suitable for arctic oil fields, desert solar plants, and marine applications where temperature fluctuations and mechanical stress are significant factors.

Typical application scenarios

In large-scale petrochemical refineries, FTA-T-21 serves as the backbone of multi-zone emergency shutdown systems. Its 16 outputs control isolation valves, pump shutdown relays, and alarm sirens across multiple processing units, while 5 inputs monitor critical pressure switch contacts and emergency stop signals. During a detected gas leak, the module’s SIL 3-certified logic ensures coordinated shutdowns of related equipment—valves close in sequence to prevent cross-contamination, and alarms activate to alert personnel—all within 10ms of detection.

Power generation facilities utilize FTA-T-21 in turbine protection systems, where its high-voltage compatibility (120/240 VAC) allows direct connection to generator circuit breakers and excitation system interlocks. The module monitors bearing temperature switches (inputs) and controls lube oil pumps and cooling water valves (outputs), ensuring rapid shutdown during abnormal conditions to prevent turbine damage. Its extended temperature range enables reliable operation in unheated turbine enclosures during winter months.

Pharmaceutical manufacturing plants deploy FTA-T-21 to manage cleanroom safety systems, where its compact design fits into space-constrained control cabinets. The module’s inputs monitor air pressure differential switches and door interlocks, while outputs control air handling unit dampers and emergency lighting. Its fail-safe design ensures cleanroom integrity is maintained during system faults, preventing product contamination and supporting regulatory compliance with FDA and EMA standards.

Honeywell FTA-T-21

Related model recommendations

Honeywell FTA-T-14: A 14-channel predecessor to FTA-T-21, suitable for smaller safety loops where lower density is sufficient, offering similar safety features in a compact form.

Honeywell FTA-AO-8: 8-channel analog output module that complements FTA-T-21 by providing proportional control signals for safety-related valves and actuators in SIS.

Honeywell Safety Manager: Central safety controller that integrates seamlessly with FTA-T-21 to execute complex shutdown logic across multiple I/O modules in large-scale systems.

Siemens SIMATIC ET 200SP F: Safety I/O module that works alongside FTA-T-21 in mixed-vendor systems, providing additional I/O capacity when standardized on Siemens PLCs.

Honeywell FC-PSU-UNI2450U: Redundant power supply optimized for FTA-T-21, ensuring stable 24 VDC power with overload protection critical for safety system reliability.

Honeywell FTA-DI-32: 32-channel digital input module that extends FTA-T-21‘s monitoring capabilities in applications requiring large numbers of sensor inputs, such as conveyor safety systems.

Installation, commissioning and maintenance instructions

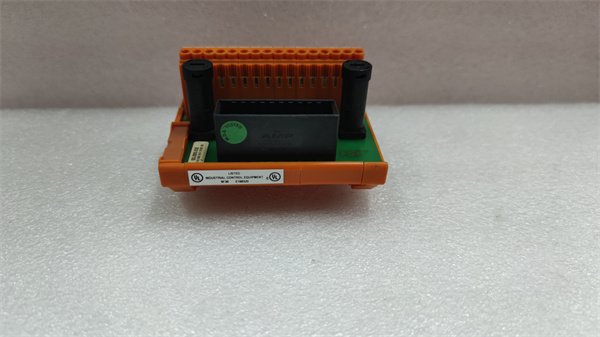

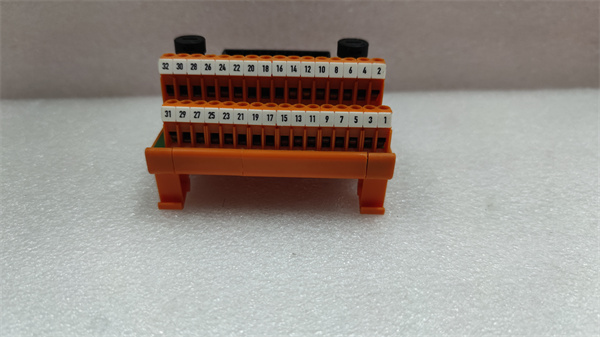

Installation preparation: Mount FTA-T-21 on a 35 mm DIN rail in a NEMA 4/IP65 enclosure for harsh environments, ensuring minimum 50 mm clearance on all sides for ventilation. Connect to a redundant 24 VDC power supply (2A per module) with dedicated grounding to meet SIL 3 requirements. Use 0.5 mm² (AWG 12) shielded cables for high-current outputs and 0.25 mm² (AWG 14) for inputs, grounding shields at both ends to prevent EMI. Verify input voltage settings (24 VDC/120/240 VAC) via the module’s DIP switches before power-up.

Commissioning and maintenance: Configure FTA-T-21 using Honeywell’s Safety Builder software, defining channel types, safety parameters, and interlock logic. Perform functional testing by simulating fault conditions (e.g., open circuits, short circuits) to verify safe-state transitions. Conduct quarterly inspections to check for loose connections, terminal corrosion, or overheating (indicated by discoloration). Calibrate diagnostic sensors annually using certified test equipment. When replacing components, use only Honeywell-approved spares to maintain SIL 3 certification and ensure fault coverage remains intact.

Service and guarantee commitment

Honeywell FTA-T-21 comes with a 24-month warranty covering manufacturing defects and ensuring compliance with SIL 3 specifications. Honeywell’s global safety support team provides 24/7 technical assistance with a 2-hour response time for critical issues, including remote diagnostics and on-site support in major industrial regions.

Customers receive access to certified training programs for FTA-T-21 configuration and maintenance, ensuring proper implementation. Extended warranty options up to 5 years include annual preventive maintenance and firmware updates. Honeywell maintains global inventory of FTA-T-21 modules, enabling 48-hour delivery for emergency replacements. All repairs use genuine components, with post-repair testing to validate SIL 3 compliance, ensuring customers maintain uncompromising safety standards.