Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FW-23-13 |

| Manufacturer | Honeywell |

| Product category | Industrial fire alarm control module |

| Input capacity | 23 addressable detection zones |

| Output circuits | 13 supervised notification circuits |

| Operating voltage | 24 VDC (18-30 VDC) |

| Standby current | 120 mA |

| Alarm current | 800 mA (max) |

| Communication protocol | Honeywell Protocol Plus |

| Operating temperature | 0°C to 50°C (32°F to 122°F) |

| Protection rating | IP30 (enclosure) |

| Dimensions | 350 mm x 250 mm x 100 mm (13.8 in x 9.8 in x 3.9 in) |

| Weight | 2.8 kg (6.2 lbs) |

| Certifications | UL 864, ULC S527, CE, FM Approved |

| Mounting type | Wall-mount (flush or surface) |

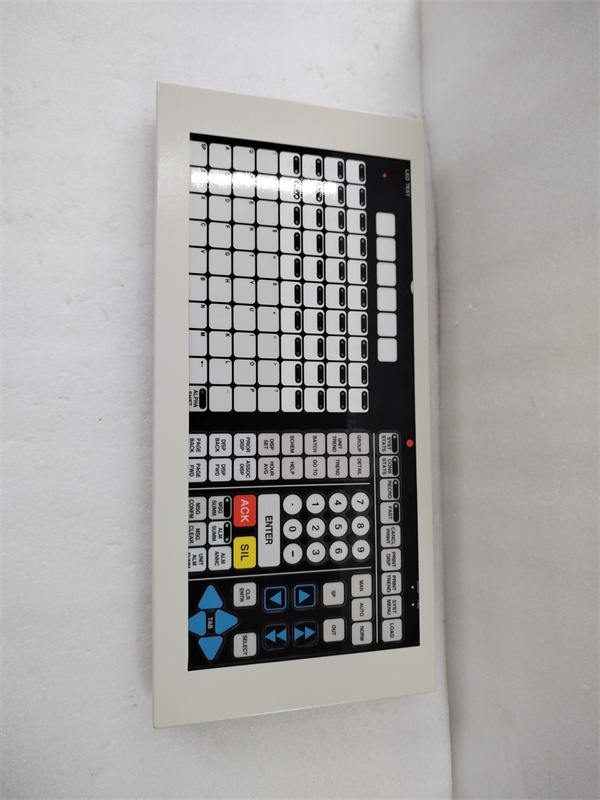

Honeywell FW-23-13

Product introduction

The Honeywell FW-23-13 is a versatile industrial fire alarm control module designed to manage and coordinate fire detection and notification systems in commercial and industrial facilities. As part of Honeywell’s FireWatcher series, this module serves as a critical intermediary between detection devices (such as smoke and flame detectors) and notification appliances (including sirens, strobes, and buzzers).

Honeywell FW-23-13 excels in medium to large-scale installations requiring segmented control over multiple detection zones. Its ability to monitor 23 addressable zones and operate 13 notification circuits allows for precise localization of fire events and targeted alarm activation, minimizing confusion during emergencies. Whether integrated into manufacturing plants, warehouses, or multi-building industrial complexes, Honeywell FW-23-13 provides reliable fire event management, ensuring timely responses that protect assets and personnel.

Core advantages and technical highlights

Zone-specific control: FW-23-13 manages 23 individual detection zones, enabling precise identification of fire locations. This segmentation allows facility managers to pinpoint the exact area of a fire event, facilitating targeted emergency responses. For example, in a large warehouse with distinct storage sections, the module can isolate alarms to the affected zone, preventing unnecessary evacuations of unaffected areas while ensuring emergency teams focus their efforts efficiently.

Flexible notification capabilities: With 13 supervised output circuits, FW-23-13 supports customized notification strategies. Each circuit can be programmed to activate specific combinations of sirens, strobes, or voice alarms based on the detected zone, ensuring appropriate alerts for different areas (e.g., louder alarms in noisy production areas, flashing strobes in low-visibility storage zones). This flexibility adapts to diverse facility layouts and operational needs.

Enhanced system supervision: The module continuously monitors the health of connected devices, including short circuits, open circuits, and low-power conditions in detection and notification circuits. Faults are immediately flagged on the integrated display, with diagnostic data transmitted to central monitoring systems via Honeywell Protocol Plus. This proactive supervision minimizes downtime by enabling predictive maintenance, such as replacing aging batteries in smoke detectors before failure.

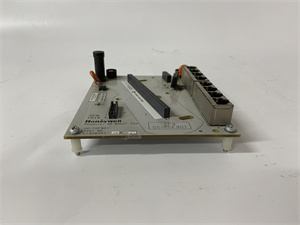

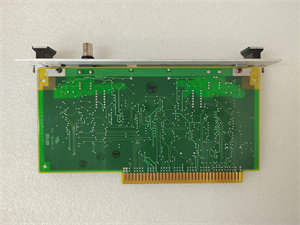

Seamless integration: FW-23-13 integrates smoothly with Honeywell’s broader fire safety ecosystem, including Honeywell F860-CA flame detectors, addressable smoke sensors, and emergency shutdown systems. It also communicates with building management systems (BMS) via standard protocols, allowing for coordinated responses like HVAC shutdown or door release activation during fire events. This interoperability reduces installation complexity and enhances overall system efficiency.

Typical application scenarios

In manufacturing facilities, FW-23-13 is deployed to monitor distinct production areas, storage zones, and administrative offices. Each production line operates as a separate detection zone, with Honeywell F860-CA flame detectors protecting high-risk areas like welding stations and chemical storage. When a fire is detected in one zone, FW-23-13 activates notification circuits specific to that area and adjacent zones, while triggering fire suppression systems only in the affected section—minimizing production disruption in unaffected parts of the facility.

Warehouse and distribution centers utilize FW-23-13 to manage fire safety across multiple storage bays and loading docks. The module’s 23 zones correspond to different storage aisles, with addressable smoke detectors providing coverage. Its 13 notification circuits control zone-specific strobes and sirens, ensuring warehouse staff can quickly identify the emergency location. Integration with conveyor control systems allows FW-23-13 to halt operations in affected zones, preventing the spread of fire through material handling equipment.

Multi-building industrial parks employ FW-23-13 as part of a networked fire safety system, with each building or wing assigned to specific zones. The module coordinates with central monitoring stations, transmitting real-time event data while activating local notifications. In the event of a fire in one building, FW-23-13 triggers alarms in that structure and adjacent facilities (to facilitate evacuation) while notifying emergency services with precise location details, streamlining response efforts.

Honeywell FW-23-13

Related model recommendations

Honeywell FW-10-6: A compact version of FW-23-13 with 10 zones and 6 notification circuits, ideal for smaller facilities like workshops or small warehouses.

Honeywell F860-CA: Flame detector that integrates with FW-23-13 to provide rapid fire detection in high-risk industrial zones, enhancing the module’s ability to trigger timely responses.

Honeywell NOTIFIER NFS2-3030: Advanced fire alarm control panel that works with FW-23-13 in large-scale systems, offering expanded zone capacity and networked capabilities.

Honeywell SPS-24DC-5A: 24 VDC power supply optimized for FW-23-13, providing stable power with backup battery support to ensure operation during mains failures.

Honeywell VORTEX R100: Voice alarm system that integrates with FW-23-13 to deliver pre-recorded emergency messages via the module’s notification circuits, enhancing evacuation guidance.

Honeywell XLS9200: Addressable fire alarm control panel that can supervise multiple FW-23-13 modules in complex industrial installations, enabling centralized management of large fire safety networks.

Installation, commissioning and maintenance instructions

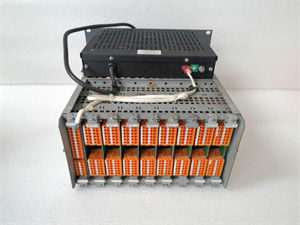

Installation preparation: Mount FW-23-13 on a flat, vibration-free wall surface (preferably in a dedicated electrical room) using the provided brackets. Ensure a minimum of 150 mm (6 inches) of clearance around the module for ventilation and access. Connect to a 24 VDC power supply with a 5A circuit breaker, incorporating a backup battery system to maintain operation for at least 24 hours during power outages. Run twisted-pair shielded cables for zone and notification circuits, separating high-voltage (AC) and low-voltage (DC) wiring to prevent interference.

Commissioning and maintenance: Configure FW-23-13 using Honeywell’s Fire Programming Software, defining zone boundaries, notification sequences, and communication settings. Test each zone by simulating alarm conditions (e.g., using test smoke for detectors, signal generators for flame detectors like Honeywell F860-CA) and verifying proper activation of corresponding notification circuits. Perform monthly tests of all functions, including fault simulation and battery backup operation. Annually, inspect wiring connections for corrosion, clean the module’s vents to prevent overheating, and update firmware to the latest version. Replace backup batteries every 3-5 years to ensure reliable standby operation.

Service and guarantee commitment

Honeywell FW-23-13 comes with a 5-year warranty covering manufacturing defects and ensuring compliance with industry standards. Honeywell’s fire safety technical support team provides 24/7 assistance, with a 2-hour response time for critical issues, including remote diagnostics and on-site support for complex installations.

Customers receive access to training programs for FW-23-13 configuration and maintenance, ensuring proper system setup. Extended warranty options up to 7 years include annual system health checks and priority technical support. Honeywell maintains regional stock of FW-23-13 modules and replacement parts, enabling next-day delivery for urgent replacements. All repairs use genuine components, with post-repair testing to validate compliance with UL 864 and other certifications, ensuring reliable performance throughout the product’s lifespan.