Description

Detailed parameter table

| Parameter name | Parameter value |

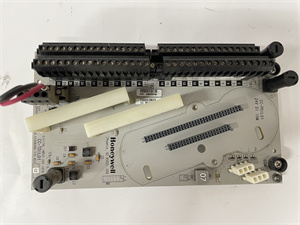

| Product model | FX-USI-0002 |

| Manufacturer | Honeywell |

| Product category | Advanced universal safety interface module |

| Input channels | 12 configurable safety inputs (24 VDC, PNP/NPN selectable) |

| Output channels | 4 safety relay outputs (Form C, 8 A @ 250 VAC) |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Operating voltage | 24 VDC ±20% |

| Power consumption | Max 12 W |

| Response time | ≤1 ms (input to output) |

| Isolation rating | 3 kV AC (input to output, input/output to ground) |

| Operating temperature | -30°C to +75°C (-22°F to +167°F) |

| Dimensions | 110 mm x 90 mm x 65 mm (4.3 in x 3.5 in x 2.6 in) |

| Weight | 0.4 kg (0.88 lbs) |

| Certifications | IEC 61508, UL 508S, CE, ATEX, IECEx |

| Mounting type | DIN rail mounting (35 mm) with push-in terminals |

Honeywell FX-USI-0002

Product introduction

The Honeywell FX-USI-0002 is an advanced universal safety interface module designed to elevate safety system performance in complex industrial environments. As an upgraded successor to Honeywell’s FE series, this module builds on proven reliability with enhanced channel capacity, higher safety integrity, and faster response times—making it suitable for demanding applications where precision and robustness are critical.

Honeywell FX-USI-0002 serves as a high-performance bridge between safety sensors (such as emergency stops, laser scanners, and safety mats) and safety controllers, enabling seamless monitoring and control of safety-critical functions. Its SIL 3 certification ensures compliance with the strictest global safety standards, providing the highest level of risk reduction for personnel and equipment. Whether deployed in high-speed manufacturing lines, heavy machinery, or hazardous process areas, Honeywell FX-USI-0002 delivers superior performance, ensuring rapid response to safety events while maintaining system availability.

Core advantages and technical highlights

Enhanced safety integrity: FX-USI-0002 achieves SIL 3 certification per IEC 61508, representing a significant upgrade over lower SIL-rated modules. This higher integrity is achieved through redundant internal circuits, 99%+ diagnostic coverage, and 2oo2D (two-out-of-two with diagnostics) architecture—ensuring it can detect and respond to faults without entering an unsafe state. This makes it ideal for applications where failure could result in severe injury, such as automated press lines or robotic assembly cells handling heavy components.

Expanded I/O capacity: With 12 configurable inputs and 4 safety relay outputs, FX-USI-0002 offers 50% more input channels and double the output capacity compared to similar modules like the FE-USI-0002. Each input supports both PNP and NPN signals without hardware modification, accommodating diverse safety devices from different manufacturers. The outputs deliver 8 A current (3 A higher than standard), enabling direct control of larger loads such as motor contactors or heavy-duty valves without external relays.

Ultra-fast response time: FX-USI-0002 achieves a response time of ≤1 ms from input signal change to output activation—twice as fast as many competing modules. This speed is critical for high-speed machinery, where even a 1 ms delay can result in measurable movement of hazardous components. For example, in a bottling line running at 500 bottles per minute, the module can stop the conveyor before a single additional bottle enters a hazardous area after a safety breach.

Ruggedized design: Built to withstand extreme conditions, FX-USI-0002 operates in temperatures from -30°C to +75°C—expanding its applicability to cold storage facilities and high-heat environments like foundries. Its 3 kV AC isolation rating provides superior protection against electrical noise and transient voltages, ensuring reliable operation in industrial environments with heavy machinery or variable frequency drives. The push-in terminals reduce wiring time by 30% compared to screw terminals, while ensuring vibration-resistant connections.

Typical application scenarios

In automotive stamping plants, FX-USI-0002 is deployed to monitor safety systems on high-speed press lines. Its 12 inputs connect to 6 emergency stop buttons, 4 light curtains (protecting access points), and 2 two-hand control stations—all critical for preventing operator contact with moving dies. The 4 outputs control the press brake motor, clutch/brake solenoid, and auxiliary equipment, ensuring immediate shutdown when any safety device is activated. The module’s SIL 3 rating meets OSHA requirements for machinery guarding, while its fast response time prevents press movement after a safety breach.

Heavy machinery manufacturing utilizes FX-USI-0002 to manage safety functions on assembly lines for construction equipment. The module monitors interlock switches on welding booth doors, laser scanners around robotic weld cells, and emergency stops along the production line. Its high-current outputs directly control weld power supplies and robotic arm drives, eliminating the need for intermediate relays. The wide temperature range ensures reliable operation in unheated factory bays during winter months, while the rugged design withstands vibration from nearby heavy equipment.

Hazardous chemical processing areas employ FX-USI-0002 to integrate safety devices in Zone 2/22 classified locations (via approved enclosures). The module’s inputs monitor gas detection alarms, emergency stop buttons, and door interlocks on chemical storage cabinets, while outputs control ventilation fans, isolation valves, and alarm horns. Its ATEX and IECEx certifications ensure safe operation in potentially explosive atmospheres, while the enhanced isolation prevents electrical interference from affecting critical safety signals.

Honeywell FX-USI-0002

Related model recommendations

Honeywell FE-USI-0002: A lower-SIL variant with 8 inputs and 2 outputs, serving as a cost-effective alternative to FX-USI-0002 for applications requiring SIL 2 integrity.

Honeywell S3000 Safety Controller: Advanced safety PLC that integrates seamlessly with FX-USI-0002 to execute complex safety logic across multiple modules in large-scale systems.

Honeywell F3SG-4RA: Light curtain system optimized for use with FX-USI-0002, providing precise detection with minimal false triggers in high-speed applications.

Honeywell 900S-ES Mushroom Button: Heavy-duty emergency stop device designed for direct connection to FX-USI-0002 inputs, featuring a 30 mm mushroom head for easy activation.

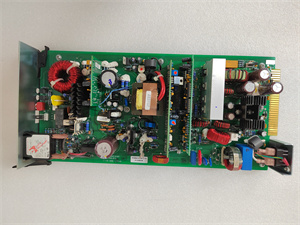

Honeywell PS24-5A-R: Redundant 24 VDC power supply with 5 A capacity, ideal for powering FX-USI-0002 in critical applications requiring uninterrupted operation.

Honeywell FTA-T-21: Safety I/O module that complements FX-USI-0002 in distributed safety systems, extending coverage to remote areas of large facilities.

Installation, commissioning and maintenance instructions

Installation preparation: Mount FX-USI-0002 on a 35 mm DIN rail in a NEMA 4/IP65 enclosure when used in dusty or wet environments. Ensure a minimum of 15 mm clearance around the module for airflow, especially in high-temperature applications. Connect to a 24 VDC power supply with 5 A overcurrent protection, using separate fused branches for power and signal circuits. Use 0.75 mm² twisted-pair shielded cable for all connections, grounding shields at both ends to meet EMC requirements. Verify input type (PNP/NPN) via DIP switches before wiring to prevent damage.

Commissioning and maintenance: Configure FX-USI-0002 using Honeywell’s Safety Builder Pro software, defining input types, output logic, and diagnostic parameters. Perform functional testing by simulating faults (e.g., open/short circuits) and verifying proper output deactivation within 1 ms using an oscilloscope. Conduct monthly visual inspections to check for terminal tightness and signs of overheating (discoloration). Annually, clean ventilation slots to prevent dust buildup and verify isolation integrity using a megohmmeter. Replace the module only with Honeywell-approved units to maintain SIL 3 certification and safety compliance.

Service and guarantee commitment

Honeywell FX-USI-0002 is backed by a 5-year warranty—the longest in its class—covering manufacturing defects and ensuring compliance with SIL 3 specifications. Honeywell’s global safety support team provides 24/7 technical assistance with a 2-hour response time for critical issues, including remote diagnostics and on-site support in major industrial regions.

Customers receive priority access to training programs for FX-USI-0002 configuration and maintenance, ensuring proper implementation of SIL 3 safety functions. Extended warranty options up to 7 years include annual safety integrity verification and firmware updates. Honeywell maintains global inventory of FX-USI-0002 modules, enabling 24-hour delivery for emergency replacements. All repairs use genuine components, with post-repair testing to validate SIL 3 compliance, ensuring customers can trust in the module’s performance for their most critical safety applications.