Description

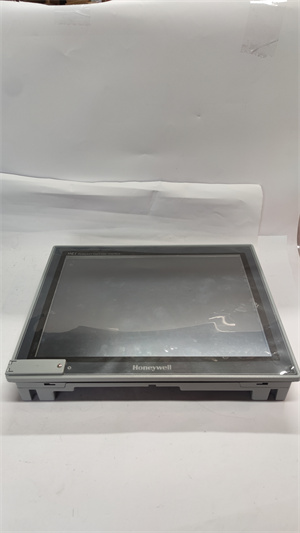

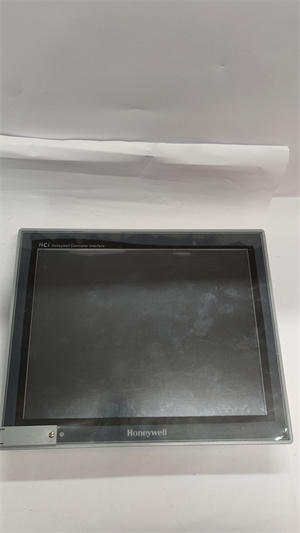

Honeywell HCIX15 – TE – FA – NC Product Description

1. Product Overview

The Honeywell HCIX15 – TE – FA – NC is a high – performance controller interface, specifically designed for use in PLC (Programmable Logic Controller) and DCS (Distributed Control System) IO (Input/Output) module applications. It serves as a crucial link between operators and control systems, enabling seamless interaction and efficient operation.

2. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | HCIX15 – TE – FA – NC |

| Manufacturer | Honeywell |

| Product Category | Controller Interface |

| Processor | 32 – bit RISC CPU |

| Display | Color TFT LCD with up to 256 real colors and wide viewing angle |

| Input Method | Resistive touch screen |

| Front Enclosure Protection | IP65F (for models without front USB port), IP64 (for models with front USB port) |

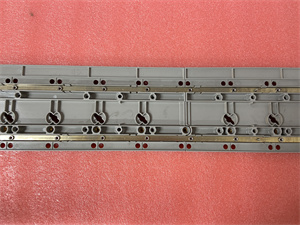

| Communication Interfaces | RS – 232C, RS – 422/485 serial ports, Ethernet. Profibus communication adapter supported |

| Data Storage | Supports CF card and USB memory interface |

| Power Supply | 24 VDC |

| Language Support | English/Korean, English/Chinese available on – screen selection |

| Software | HCIX Designer software included |

| Warranty | Warranty service provided |

Honeywell HCIX15-TE-FA-NC

3. Product Introduction

This controller interface offers a user – friendly experience with its standard – equipped color TFT LCD display. The high – quality display not only shows up to 256 real colors but also has a wide viewing angle, ensuring clear visibility from various positions. The resistive touch – screen input method allows operators to directly interact with the system, making parameter changes much more straightforward compared to traditional keyboard – based operations.

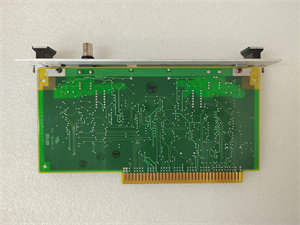

The HCIX15 – TE – FA – NC is powered by a 32 – bit RISC CPU, which enables high – speed graphic processing. This processing power is essential for quickly rendering complex visualizations, such as real – time process monitoring dashboards, in industrial control applications.

4. Core Advantages and Technical Highlights

4.1 High – Speed Data Transfer

With its 32 – bit RISC CPU, the HCIX15 – TE – FA – NC can rapidly process and transfer data. This is particularly beneficial in industrial settings where real – time data handling is critical. For example, in a manufacturing plant with a large number of sensors and actuators, the controller interface can quickly receive data from sensors, process it, and send control signals to actuators without significant latency.

4.2 Versatile Communication Capabilities

Featuring RS – 232C, RS – 422/485 serial ports, and Ethernet as standard, the HCIX15 – TE – FA – NC can easily integrate with a wide range of devices and systems. Additionally, the support for the Profibus communication adapter expands its compatibility further. This versatility allows it to be used in diverse industrial networks, whether it’s a small – scale local control system or a large – scale, multi – node distributed control network.

4.3 Robust Enclosure Protection

The IP65F front enclosure protection for models without a front USB port makes the HCIX15 – TE – FA – NC suitable for use in harsh environments. It can withstand exposure to moisture, dust, and other contaminants, ensuring reliable operation even in tough industrial conditions. For models with a front USB port, the IP64 rating still provides a high level of protection against splashing water and dust ingress.

4.4 Easy Data Storage and Management

The ability to support CF card and USB memory interfaces simplifies data storage. High – capacity data can be logged directly to these storage devices, and then analyzed and printed using the supplied CF viewer application program. This is extremely useful for archiving historical process data, which can be used for performance analysis, troubleshooting, and compliance reporting in industrial processes.

4.5 Multi – Language Support

The on – screen language selection feature, offering options like English/Korean or English/Chinese, makes the HCIX15 – TE – FA – NC accessible to a global user base. In multinational industrial plants or in regions with diverse language requirements, this multi – language support ensures that operators can interact with the system in their preferred language, reducing the risk of misoperation due to language barriers.

4.6 Powerful Design Software

The included HCIX Designer software provides a wide variety of design tools. Objects such as numerals, lamps, messages, alarms, keypads, graphs, animations, and windows can be easily incorporated into custom – designed graphics. This software simplifies the creation of monitoring and operating displays, allowing engineers to design intuitive user interfaces without complex register addressing.

5. Typical Application Scenarios

5.1 Industrial Automation

In industrial automation systems, the HCIX15 – TE – FA – NC can be used as a central control interface. It can be connected to PLCs that control the operation of various machinery, such as conveyor belts, robotic arms, and assembly lines. Operators can use the touch – screen interface to monitor the status of these machines, adjust process parameters, and receive real – time alarms in case of any malfunctions. For example, in an automotive manufacturing plant, the HCIX15 – TE – FA – NC can be used to control and monitor the production line, ensuring smooth and efficient operation.

5.2 Process Control in Manufacturing

In manufacturing processes, especially those involving chemical reactions or material handling, the HCIX15 – TE – FA – NC can be used to control and monitor process variables. It can be connected to sensors that measure parameters such as temperature, pressure, and flow rate, and to actuators that adjust valves, pumps, and heaters. Operators can use the color TFT LCD display to view real – time process data and use the touch – screen to make necessary adjustments. For instance, in a pharmaceutical manufacturing plant, the HCIX15 – TE – FA – NC can be used to control the production process of drugs, ensuring product quality and safety.

5.3 Building Automation

In building automation systems, the HCIX15 – TE – FA – NC can be used to control and monitor various building systems, such as heating, ventilation, and air – conditioning (HVAC), lighting, and security systems. It can be connected to building management system (BMS) controllers, allowing operators to view and control the status of these systems from a single interface. For example, in a large commercial building, the HCIX15 – TE – FA – NC can be used to adjust the temperature settings of the HVAC system, turn lights on or off, and monitor security camera feeds.

Honeywell HCIX15-TE-FA-NC

6. Installation, Commissioning and Maintenance Instructions

6.1 Installation Preparation

Mount the HCIX15 – TE – FA – NC in a location that is easily accessible to operators. Ensure that the mounting surface is flat and can support the weight of the device.

Connect the 24 VDC power supply to the appropriate terminals on the device. Use a power cable with the appropriate gauge to handle the current requirements.

Connect the communication cables (RS – 232C, RS – 422/485, or Ethernet) to the corresponding ports on the HCIX15 – TE – FA – NC and the devices it will communicate with. Make sure the connections are tight and secure to prevent signal loss or interference.

If using a CF card or USB memory for data storage, insert the storage device into the appropriate slot on the device.

6.2 Commissioning

Before powering on the HCIX15 – TE – FA – NC, double – check all the connections to ensure they are correct.

Power on the device and wait for it to boot up. The color TFT LCD display should show the startup screen.

Use the touch – screen to navigate through the initial setup menu. Set the language preference, date, and time if required.

Test the communication interfaces by sending and receiving test data to/from the connected devices. Ensure that the data transfer is accurate and stable.

If using the HCIX Designer software to create custom graphics, download the designed files to the HCIX15 – TE – FA – NC using the appropriate communication method (RS – 232C, Ethernet, or USB).

6.3 Maintenance

Periodically clean the touch – screen display using a soft, dry cloth to ensure clear visibility and proper touch response.

Check the communication cables for any signs of damage or loose connections. If any issues are detected, replace the cable or re – secure the connection.

Monitor the data storage capacity of the CF card or USB memory. If the storage is nearly full, transfer the archived data to a computer for long – term storage and free up space on the storage device.

Update the firmware of the HCIX15 – TE – FA – NC regularly to ensure optimal performance and to take advantage of any new features or bug fixes provided by Honeywell.

7. Service and Guarantee Commitment

Honeywell provides warranty service for the HCIX15 – TE – FA – NC. In the event of a manufacturing defect, Honeywell’s dedicated support team is available to provide technical assistance. If the device fails within the warranty period, Honeywell will repair or replace the unit, subject to the terms and conditions of the warranty.

Customers can access detailed installation and operation manuals on Honeywell’s official website. These manuals provide step – by – step instructions for installation, commissioning, and maintenance of the HCIX15 – TE – FA – NC. Additionally, Honeywell may offer training programs for customers who want to learn more about the proper use and integration of this controller interface in industrial applications.