Description

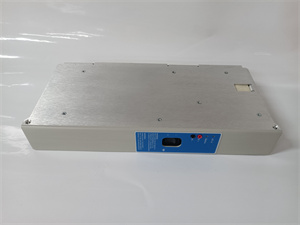

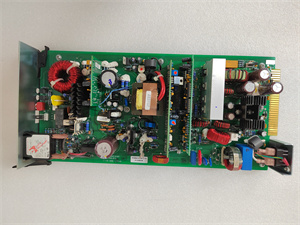

Honeywell RC-SCONTRL

- •

Model Number: RC-SCONTRL - •

Manufacturer: Honeywell - •

Product Type: Safety Logic Controller Module - •

Safety Standard: IEC 61508 SIL 3 (Hardware Fault Tolerance ≥2) - •

Processor Architecture: Dual-redundant (active/standby), 32-bit RISC processors - •

Logic Execution Speed: 10,000 logic elements per millisecond - •

Communication Protocols: Safety Network (proprietary), Modbus TCP, HART 7 (for smart device diagnostics) - •

Number of I/O Points Supported: Up to 256 (via connected safety I/O modules) - •

Operating Temperature: -40°C to +70°C - •

Power Supply: 24V DC (nominal, 18-30V DC range), redundant inputs - •

Power Consumption: 15W (typical, dual processors active) - •

Dimensions: 150mm x 100mm x 75mm (width x height x depth, rack-mountable) - •

Weight: 0.8kg - •

Certifications: CE, UL, ATEX Zone 1 (optional), FM Approved - •

Hot Swap Support: Yes (redundant processor allows online replacement of standby unit) Honeywell RC-SCONTRL