Description

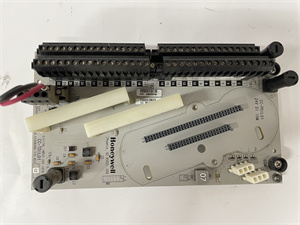

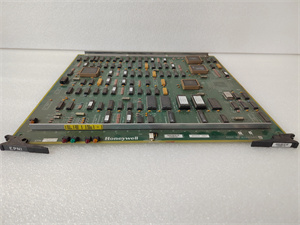

Honeywell RM7890B1014/U

- •

Model Number: RM7890B1014/U - •

Manufacturer: Honeywell - •

Product Type: Burner Control Module - •

Input Voltage: 120/240V AC ±10% (50/60 Hz) - •

Fuel Compatibility: Natural gas (NG), light oil (LO), combination NG/LO - •

Safety Certifications: UL/cUL Listed, FM Approved, EN 298 Compliant - •

Operating Temperature: -40°C to +66°C (-40°F to +151°F) - •

Flame Detection: UV/IR sensor compatibility (supports Honeywell C7027, C7035) - •

Sequence Stages: Purge, pilot trial, main flame trial, run, post-purge - •

Diagnostic Indicators: LED status lights (power, flame, fault, lockout) - •

Dimensions: 127mm x 127mm x 76mm (5.0in x 5.0in x 3.0in) - •

Weight: 0.45kg (1.0lb) - •

Communication: Auxiliary relay outputs (5A @ 240V AC) for external signaling - •

Enclosure Rating: NEMA 1 (indoor use) Honeywell RM7890B1014/U