Description

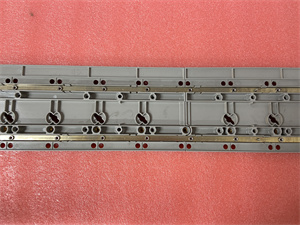

Honeywell S7800A1068

- •

Model Number: S7800A1068 - •

Manufacturer: Honeywell - •

Product Type: Flame Detector - •

Detection Principle: UV/IR composite (UV: 190-290 nm; IR: 4.3 μm hydrocarbon band) - •

Response Time: <5 seconds (flame detection to output activation) - •

Viewing Angle: 90° conical field of view - •

Spectral Sensitivity: UV (flame ignition), IR (continuous combustion monitoring) - •

Output Type: Dry contact (SPDT relay, 5A @ 250V AC / 30V DC) - •

Operating Temperature: -40°C to +70°C - •

Humidity Range: 5% to 95% non-condensing - •

Power Supply: 24V DC (nominal, 18-30V DC range) - •

Power Consumption: 2W (typical) - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 1/2 (gas/dust), FM Approved - •

Dimensions: 120mm x 80mm x 60mm (height x width x depth, with mounting bracket) - •

Weight: 0.5kg - •

Diagnostics: Self-test mode, signal strength indicator, contamination warning Honeywell S7800A1068