Description

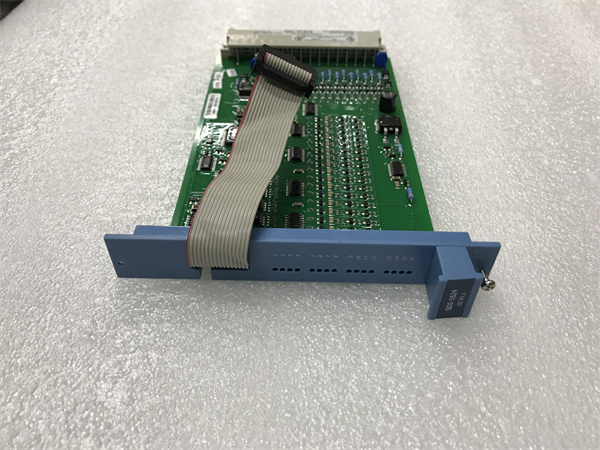

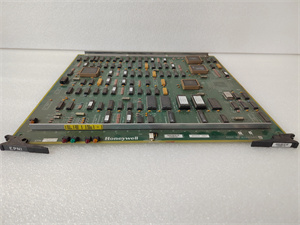

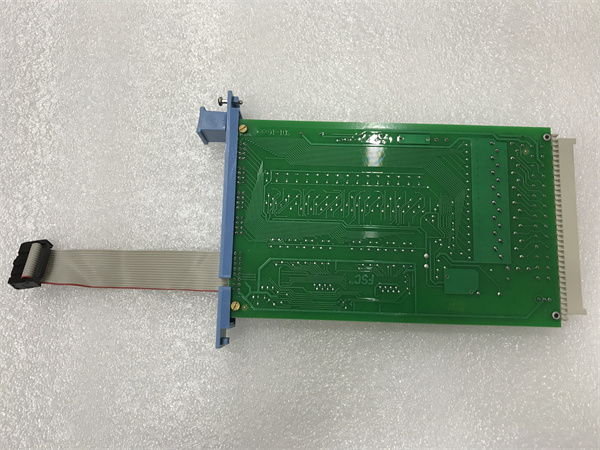

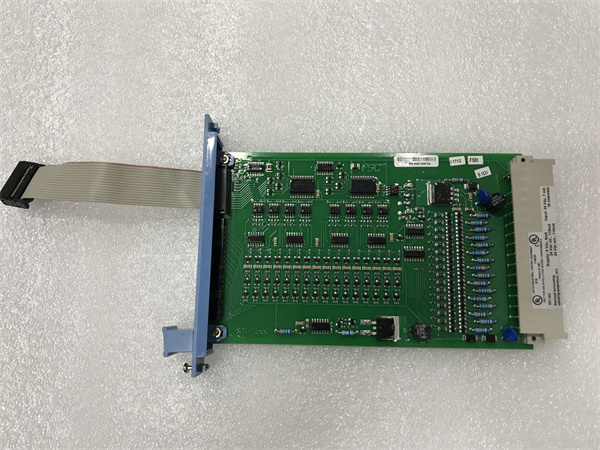

Honeywell SDI – 1624 Product Description

1. Product Overview

The Honeywell SDI – 1624 is a high-performance digital input module, meticulously designed to cater to the rigorous demands of industrial automation and control systems. It serves as a vital link in industrial processes, efficiently collecting and processing digital input signals from an array of field devices. Compatible with both Honeywell’s safety-critical systems and general industrial control setups, this module ensures accurate and timely data transmission, contributing to the smooth and safe operation of various industrial processes.

2. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SDI – 1624 |

| Manufacturer | Honeywell |

| Product Category | Digital Input Module |

| Number of Input Channels | 16 |

| Power Supply | 5 VDC (10 mA), 24 VDC (Internal: 120 mA, External: 120 mA for input currents) |

| Input Voltage Range | 18 VDC – 30 VDC |

| Input Current | 8 mA at 24 VDC |

| Input High Threshold | > 16 VDC |

| Input Low Threshold | < 8 VDC (with current < 1.5 mA) |

| Input Delay | Typically 8 ms |

| Input Type | 24 VDC solid – state, reverse polarity protected |

| Maximum Current | 500 mA |

| Max. Load Capacitance | 40 μF |

| Voltage Drop | < 1.2 V at 500 mA |

| Operating Temperature Range | – 40 °C to + 75 °C |

| Storage Temperature Range | – 60 °C to + 90 °C |

| Humidity | 5% – 95% non – condensing |

| Enclosure Rating | IP67 |

| Dimensions (approx.) | 10 cm x 8 cm x 6 cm |

| Weight | 0.15 kg |

| Approvals | CE, TÜV, UL, CSA, ATEX |

| Space Requirements | 4 TE, 3 HE (equivalent to 4 HP, 3 U) |

| Ripple Content (on 5 VDC) | < 0.3 Vp – p (0 – 360 Hz) |

Honeywell SDI-1624

3. Product Introduction

The SDI – 1624 is crafted with a focus on high performance, durability, and ease of integration. Its 16 digital input channels offer ample capacity to connect with various field devices like proximity sensors, limit switches, and emergency buttons. The solid-state input design, coupled with reverse polarity protection, ensures long-term reliable operation even in harsh industrial environments prone to electrical anomalies.

Featuring a tool-less snap-in mounting mechanism for standard DIN EN rails, the module simplifies installation. The spring-clamp terminals for field wiring facilitate quick and secure connections, reducing installation time and minimizing the risk of wiring errors. This design not only enhances installation efficiency but also simplifies maintenance and troubleshooting procedures.

4. Core Advantages and Technical Highlights

4.1 Enhanced Input Channel Performance

With 16 input channels, the SDI – 1624 provides a high-density solution for industrial control systems. Each channel is optimized for fast response, ensuring that even rapid changes in input signals are captured accurately. This makes it ideal for applications where real-time monitoring of multiple devices is crucial, such as high-speed production lines, where timely detection of component positions or machine states is essential.

4.2 Superior Power Management

The SDI – 1624 boasts an advanced power management system, operating on 5 VDC and 24 VDC power supplies. The 24 VDC power supply for input circuitry is designed to handle voltage fluctuations within a wider range (18 – 30 VDC), making it more adaptable to unstable power conditions in industrial settings. This robust power handling capability ensures consistent performance even when the power supply is not perfectly stable.

4.3 Advanced Isolation Technology

Equipped with enhanced galvanic isolation, the SDI – 1624 provides superior protection against electrical noise, ground loops, and voltage surges. This isolation not only safeguards the control system from potential damage but also ensures the integrity of the input signals. In environments with high electromagnetic interference, such as near heavy machinery or power distribution systems, this feature is vital for maintaining accurate data transmission.

4.4 Comprehensive Fault Monitoring

The module incorporates advanced fault monitoring and diagnostic functions. It continuously scans each input channel for faults such as short circuits, open circuits, overvoltage, and undervoltage. When a fault is detected, it generates detailed fault codes and status indicators, enabling quick identification and resolution of issues. This proactive fault management reduces downtime and enhances the overall reliability of the industrial control system.

4.5 Extended Environmental Tolerance

Designed to operate in an extended temperature range of – 40 °C to + 75 °C, the SDI – 1624 is suitable for use in extreme environmental conditions. Whether in freezing cold storage facilities, hot steel mills, or humid chemical plants, the module maintains stable performance. Its IP67 enclosure rating provides excellent protection against dust and water immersion, ensuring durability in harsh and wet industrial environments.

4.6 Robust Construction

The SDI – 1624 is built with high-quality, rugged materials that can withstand vibrations, shocks, and exposure to industrial contaminants. The sturdy enclosure and internal components are designed to meet stringent industrial standards, ensuring a long service life even in demanding operating conditions. This robust construction minimizes the need for frequent replacements and reduces maintenance costs.

5. Typical Application Scenarios

5.1 Process Control Systems

In chemical, pharmaceutical, and food processing plants, the SDI – 1624 is used to monitor the status of various process equipment. It can detect the open/close positions of valves, the on/off states of pumps, and the presence/absence of materials on conveyors. By providing real-time input signals to the process control system, it enables precise control of the production process, ensuring product quality and consistency.

5.2 Material Handling Systems

In warehouses and distribution centers, material handling systems rely on the SDI – 1624 to monitor the movement of goods. It can detect the position of palletizers, the status of conveyor belts (running/stopped), and the presence of packages at specific points. This information is used to coordinate the operation of the material handling equipment, optimizing the flow of goods and improving operational efficiency.

5.3 Machine Safety Systems

Machine safety systems in manufacturing facilities utilize the SDI – 1624 to monitor safety devices such as emergency stop buttons, safety gates, and light curtains. When a safety device is triggered, the module quickly transmits the signal to the safety controller, which initiates a safe shutdown of the machine. This rapid response helps prevent accidents and protects the safety of operators.

5.4 Building Automation Systems

In large commercial and industrial buildings, the SDI – 1624 is integrated into building automation systems to monitor various building components. It can detect the status of doors (open/closed), windows, and lighting fixtures. This data is used to control heating, ventilation, and air conditioning (HVAC) systems, security systems, and lighting, optimizing energy consumption and enhancing building comfort and security.

Honeywell SDI-1624

6. Installation, Commissioning and Maintenance Instructions

6.1 Installation Preparation

Choose a suitable location within the control cabinet for mounting the SDI – 1624. Ensure the location is away from sources of excessive heat, moisture, and strong electromagnetic fields.

Inspect the module for any physical damage before installation. Check the terminals, enclosure, and connectors for signs of wear or damage.

Prepare the power supply cables and field wiring according to the specified requirements. Use cables of the correct gauge and insulation rating to ensure safe and reliable operation.

Gather the necessary tools, including screwdrivers, wire strippers, and a multimeter, for installation and testing.

6.2 Commissioning

Mount the SDI – 1624 on the DIN EN rail using the tool-less snap-in mechanism, ensuring a secure fit.

Connect the power supply cables to the appropriate terminals, following the wiring diagram in the product manual. Verify that the power supply voltage is within the specified range (5 VDC and 24 VDC).

Connect the field wiring to the spring-clamp terminals, ensuring secure connections. Label each wire to correspond with the input channel for easy identification.

Power on the control system and the SDI – 1624 module. Use diagnostic software or tools to verify that the module is recognized by the control system and that all input channels are functioning properly.

Test each input channel by applying a suitable input signal (e.g., closing a switch) and confirming that the module correctly detects and transmits the signal to the control system. Adjust input thresholds if necessary for accurate detection.

6.3 Maintenance

Conduct regular visual inspections of the SDI – 1624 module to check for signs of physical damage, loose connections, or corrosion. Inspect the enclosure for cracks or damage that may compromise its protection rating.

Clean the module periodically using a soft, dry cloth to remove dust and debris. Avoid using harsh chemicals or solvents that may damage the enclosure or components.

Check the power supply and field wiring connections regularly to ensure they are tight and secure. Look for signs of frayed wires, corrosion, or overheating.

Utilize the module’s diagnostic functions to monitor its performance. Check for fault codes or status indicators that may indicate issues with input channels or internal components.

Refer to the product manual and Honeywell’s technical bulletins for recommended maintenance procedures and firmware updates. Perform updates as necessary to ensure optimal performance.

7. Service and Guarantee Commitment

Honeywell provides a 12 – month warranty for the SDI – 1624, covering manufacturing defects. If the module fails within the warranty period due to a manufacturing defect, Honeywell’s technical support team will provide prompt assistance, including troubleshooting, repair, or replacement, in accordance with the warranty terms.

Customers can access detailed installation, operation, and maintenance manuals for the SDI – 1624 on Honeywell’s official website. These resources offer step-by-step guidance to ensure proper installation, commissioning, and maintenance. Additionally, Honeywell may offer training programs to help customers gain a deeper understanding of the module’s features, integration, and operation, ensuring they can maximize its performance and reliability in their industrial control systems.