Description

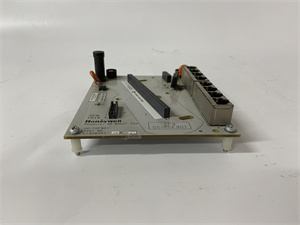

Honeywell TC-IOLI01 51403427-125

- •

Model Number: TC-IOLI01 51403427-125 - •

Manufacturer: Honeywell - •

Product Type: I/O Link Interface Module - •

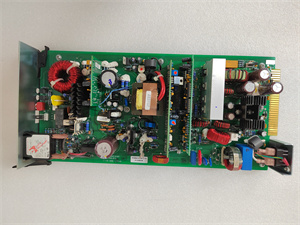

Bus Protocol: Honeywell I/O Link (proprietary, for C300 controller-remote I/O communication) - •

Number of Channels: 2 (redundant, independent operation) - •

Data Rate: 10 Mbps (max, per channel) - •

Isolation Voltage: 2500VAC (channel-to-bus, channel-to-ground) - •

Operating Temperature: -40°C to +70°C - •

Power Supply: 24V DC (nominal, 18-30V DC range) from C300 chassis - •

Power Consumption: 2.5W (typical, dual channels active) - •

Certifications: SIL 2 (IEC 61508), CE, UL, ATEX Zone 2 (optional) - •

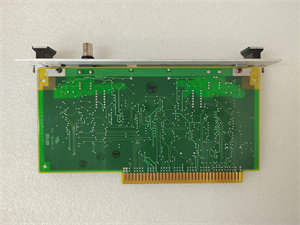

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits C300 I/O slot) - •

Weight: 0.21kg - •

Diagnostics: Link status (tx/rx), CRC errors, port fault, power monitoring, redundancy state - •

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) Honeywell TC-IOLI01 51403427-125