Description

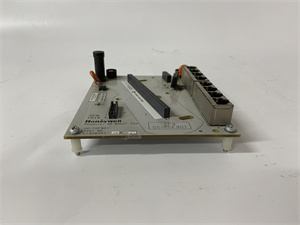

Honeywell TK-PPD011

- •

Manufacturer: Honeywell - •

Model: TK-PPD011 - •

Product Number: 51309241-175 - •

Product Type: DCS I/O Module (Process Control Card) - •

Series: Experion PKS - •

Communication Protocols: Modbus RTU/ASCII (supports master/slave modes); compatible with HART (optional, depending on configuration). - •

I/O Capabilities: - •

Analog Inputs: Supports 4-20mA, 0-10V, and other common industrial signals (exact number of channels varies by setup). - •

Digital Inputs: Handles dry contact or wet signals (e.g., 24V DC) from switches, sensors, or relays. - •

Digital Outputs: Provides relay or transistor outputs for controlling actuators (e.g., valves, pumps).

- •

- •

Power Supply: 24V DC (nominal), with a tolerance of ±15% (typical; exact requirements may vary by application). - •

Operating Temperature: -20°C to +70°C (suitable for outdoor or harsh indoor environments). - •

Storage Temperature: -40°C to +85°C. - •

Humidity Range: 5% to 95% non-condensing. - •

Dimensions: Compact form factor (e.g., 100mm x 50mm x 30mm; exact size may vary by configuration). - •

Weight: Lightweight design (e.g., 0.2kg; exact weight may vary by configuration). - •

Certifications: CE, UL, ATEX Zone 2 (optional, depending on regional requirements). Honeywell TK-PPD011

- •

Chemical Plants: Monitors and controls pressure, temperature, and flow of chemicals in reactors and pipelines. For example, in a fertilizer plant, the module can adjust the flow of ammonia and urea to maintain optimal reaction conditions. - •

Oil and Gas Refineries: Tracks liquid levels in storage tanks, monitors pipeline pressure, and controls valves to prevent leaks. In a crude oil refinery, the module can send alerts if a tank level exceeds a safe threshold, allowing operators to take corrective action. - •

Power Generation Facilities: Controls turbine speed, monitors generator output, and manages cooling systems. In a natural gas power plant, the module can adjust the fuel flow to the turbine to maintain consistent electricity generation. - •

Manufacturing Plants: Oversees conveyor belt systems, robotic arms, and packaging machines. In an automotive assembly plant, the module can control the movement of parts along a conveyor belt, ensuring efficient production. - •

Water and Wastewater Treatment: Monitors pump status, water levels, and chemical dosing in treatment plants. In a municipal wastewater facility, the module can adjust the flow of water through filters to ensure clean effluent.