Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 |

| Manufacturer | Honeywell |

| Product Category | Universal Dual – Input Analytical Analyzer for Conductivity |

| Input Types | CC1 = Conductivity, CC2 = Conductivity |

| Output Types | 2 Standard Analog Outputs (4 – 20 mA or 0 – 10 V selectable), with Option for Additional Outputs (none in this model as denoted by ‘NN’) |

| Accuracy | ±0.5% of reading for conductivity measurements |

| Communication Protocols | HART 7, Modbus RTU (via RS – 485), Ethernet (for web – server access and data transfer) |

| Operating Voltage | 12 – 42 V DC |

| Power Consumption | Max 3 W |

| Operating Temperature | – 20°C to +60°C (- 4°F to +140°F) |

| Protection Rating | IP65 (suitable for general industrial environments with protection against dust and water jets) |

| Dimensions | 144 mm x 144 mm x 100 mm (5.67 in x 5.67 in x 3.94 in) |

| Weight | 0.5 kg (1.1 lbs) |

| Certifications | CE, CSA, FM, UL |

| Mounting Type | Panel mount (standard), with options for wall or pipe mounting using additional accessories |

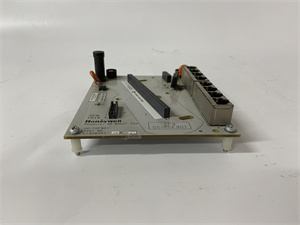

Honeywell UDA2182-CC1-CC2-NN-N-0000-E8-000

Product Introduction

The Honeywell UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 is a high – performance universal dual – input analytical analyzer specifically designed for accurately measuring and monitoring conductivity levels in various industrial liquid processes. As part of Honeywell’s advanced UDA2182 series, this analyzer is engineered to meet the demands of industries where precise conductivity measurement is crucial for process control and quality assurance.

This analyzer is highly versatile, capable of handling two independent conductivity inputs. It converts the raw conductivity sensor data into standardized analog signals that can be easily integrated with Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and other industrial control platforms. Whether it’s ensuring the quality of water in power generation plants, maintaining the right chemical balance in pharmaceutical manufacturing, or optimizing processes in food and beverage production, the Honeywell UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 provides reliable and accurate conductivity measurements.

Core Advantages and Technical Highlights

Dual – Input Conductivity Monitoring

The UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 features two dedicated conductivity inputs (CC1 and CC2), allowing for simultaneous monitoring of conductivity in two different process streams or at two different points within a single process. This is extremely useful in applications such as water treatment plants, where it can monitor the conductivity of both the influent and effluent water. Each input channel can be independently calibrated and configured, providing flexibility in adapting to different conductivity ranges and sensor types.

High – Precision Measurement

With an accuracy of ±0.5% of the reading, this analyzer offers highly precise conductivity measurements. In industries like semiconductor manufacturing, where even slight variations in the conductivity of process liquids can impact product quality, the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 ensures that the conductivity levels are monitored with utmost precision. The analyzer uses advanced signal processing algorithms to filter out noise and interference, resulting in stable and reliable measurements.

Versatile Output Options

Equipped with two standard configurable analog outputs (4 – 20 mA or 0 – 10 V), the analyzer can transmit the processed conductivity data to multiple control systems or devices. For example, it can send data to a local PLC for real – time process control and to a SCADA system for historical data logging and analysis. Although this particular model (‘NN’) does not have additional analog outputs or relays, the base analog outputs are galvanically isolated from the inputs and power supply, ensuring signal integrity and preventing ground loops in complex wiring setups.

Robust Communication Capabilities

The UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 supports HART 7 and Modbus RTU (via RS – 485) communication protocols, enabling seamless integration with a wide range of industrial control systems. Additionally, it features Ethernet connectivity, which allows for web – server access. This means that operators can remotely monitor and configure the analyzer from any device with a web browser, as long as it is on the same network. This is especially beneficial for large – scale industrial plants where remote monitoring and control can significantly reduce maintenance and operational costs.

Wide Operating Environment

Rated to operate in temperatures ranging from – 20°C to +60°C, the analyzer can withstand harsh industrial environments. Its IP65 protection rating shields it from dust and water jets, making it suitable for installation in areas with high humidity or where there is a risk of water splashing. This robust design ensures reliable operation in various industrial settings, from the humid conditions of paper mills to the dusty environments of mining operations.

Typical Application Scenarios

Power Generation

In power generation plants, the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 is used to monitor the conductivity of boiler feedwater and cooling water. By accurately measuring the conductivity, operators can detect any impurities or changes in the water chemistry that could potentially cause corrosion or scaling in the boilers and cooling systems. For example, an increase in conductivity of the boiler feedwater may indicate a problem with the water treatment process, and the analyzer’s data can be used to trigger corrective actions in real – time. The Ethernet communication allows for remote monitoring of these critical water parameters, ensuring the smooth operation of the power generation process.

Pharmaceutical Manufacturing

Pharmaceutical companies rely on the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 to monitor the conductivity of purified water used in the production process. In pharmaceutical manufacturing, the quality of water is of utmost importance, and even minor changes in conductivity can affect the quality of the final product. The analyzer’s high – precision measurement capabilities ensure that the conductivity of the water remains within the strict quality control limits. The dual – input feature can be used to monitor the conductivity of water at different stages of the purification process, such as before and after the reverse osmosis system.

Food and Beverage Production

In the food and beverage industry, the analyzer is used to monitor the conductivity of process water, as well as in cleaning – in – place (CIP) systems. In process water applications, it helps ensure that the water used in production meets the required quality standards. For CIP systems, the conductivity measurement can indicate the effectiveness of the cleaning solution and the presence of any contaminants. For example, if the conductivity of the cleaning solution after a CIP cycle is outside the expected range, it may mean that the equipment has not been properly cleaned. The analyzer’s communication capabilities enable seamless integration with the plant’s overall control system, allowing for efficient monitoring and control of these processes.

Honeywell UDA2182-CC1-CC2-NN-N-0000-E8-000

Related Model Recommendations

Honeywell UDA2182 – CC1 – NN – NN – N – 0000 – E8 – 000: A single – input variant of the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000, suitable for applications where only one conductivity measurement is required. It offers a more cost – effective solution for smaller – scale operations or processes with a single critical conductivity measurement point.

Honeywell STT850 (with conductivity option): A smart transmitter that can be used in conjunction with the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 for enhanced conductivity measurement accuracy. It provides additional diagnostic capabilities and can be used to pre – process the conductivity sensor signals before they are sent to the analyzer.

Honeywell LG1093AC01: An advanced process controller that can integrate the output signals from the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000. The controller can use the conductivity data for closed – loop control of complex processes, such as adjusting the dosage of chemicals in a water treatment process based on the measured conductivity.

Honeywell PM500: A power monitor that can work in tandem with the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 in industrial facilities. It can help in analyzing the energy consumption associated with the processes being monitored by the conductivity analyzer, providing a more comprehensive view of the overall process efficiency.

Honeywell T9000: A remote I/O module that can interface with the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 in distributed systems. It can be used to expand the monitoring capabilities by aggregating data from multiple conductivity analyzers or other field devices.

Honeywell HART Communicator: A handheld device used to configure and calibrate the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000. It enables on – site parameter adjustments and diagnostics, allowing technicians to quickly troubleshoot any issues with the analyzer.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Mount the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 using the provided panel – mounting hardware. Ensure that the location is free from excessive vibration, direct sunlight, and corrosive substances. For wall or pipe mounting, use the appropriate mounting accessories.

Connect the analyzer to a 12 – 42 V DC power supply, ensuring that the power source has the appropriate over – current protection.

Use shielded cables for connecting the conductivity sensors to the analyzer’s input terminals. Ground the shield at the analyzer end to minimize electromagnetic interference.

For hazardous areas, verify that the installation complies with the relevant certifications (CE, CSA, FM, UL). Although the analyzer is not specifically designed for use in highly hazardous (e.g., explosion – prone) areas out of the box, proper installation in areas with lower – level hazards can be achieved by following the certification guidelines.

Commissioning and Maintenance

Configure the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 using a HART communicator or Honeywell’s Field Device Manager software. Set the input types (conductivity), measurement ranges, and output scaling according to the requirements of the process.

Perform a zero and span calibration using certified conductivity standards. For example, use a standard conductivity solution with a known value to calibrate the analyzer. This should be done during initial installation and periodically thereafter.

Verify the communication with the control system by checking the signal transmission and response to parameter changes. Ensure that the HART, Modbus RTU, and Ethernet connections are working correctly.

Inspect the analyzer monthly for any loose connections, signs of physical damage, or abnormal operation. Check the display for any error messages.

Calibrate the analyzer annually using NIST – traceable equipment to maintain the accuracy of the conductivity measurements.

Update the firmware of the analyzer when new versions are available. This can be done via HART or Ethernet, and it may provide enhanced features, improved accuracy, or better compatibility with other devices.

Service and Guarantee Commitment

Honeywell UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 comes with a 3 – year warranty covering manufacturing defects and ensuring compliance with the published performance specifications. Honeywell’s dedicated field device support team provides 24/7 technical assistance, with a 4 – hour response time for critical issues. This includes remote diagnostics, where technicians can access the analyzer remotely to identify and resolve problems without the need for on – site visits in many cases.

Customers receive access to detailed installation guides and HART configuration manuals for the UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000, which support efficient setup and operation. Extended warranty options up to 5 years are available, which include annual calibration verification and priority replacement service. Honeywell maintains a global inventory of UDA2182 – CC1 – CC2 – NN – N – 0000 – E8 – 000 units, enabling quick delivery for emergency replacements. All repairs use genuine Honeywell components, and post – repair testing is carried out to validate accuracy and certification compliance, ensuring reliable performance in critical process applications.