Description

Detailed parameter table

| Parameter name | Parameter value |

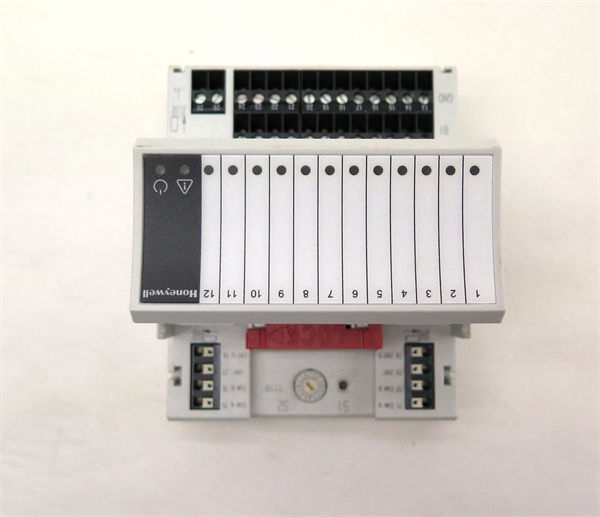

| Product model | XF823A |

| Manufacturer | Honeywell |

| Product category | Advanced building automation controller |

| Processing power | 32-bit ARM Cortex-A53 processor, 1.2 GHz |

| Memory | 1 GB RAM, 8 GB flash storage |

| I/O capacity | 16 universal inputs, 12 relay outputs, 6 analog outputs |

| Communication protocols | BACnet/IP, BACnet MS/TP, Modbus RTU/TCP, LonWorks, Wi-Fi (optional) |

| Operating voltage | 24 VAC/DC (18-30 V range) |

| Power consumption | Max 18 W |

| Operating temperature | -10°C to 60°C (14°F to 140°F) |

| Dimensions | 240 mm x 180 mm x 90 mm (9.4 in x 7.1 in x 3.5 in) |

| Weight | 1.5 kg (3.3 lbs) |

| Certifications | UL 916, CE, BTL Certified, ISO 16484-5 |

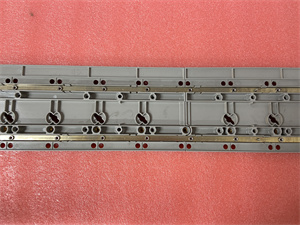

| Mounting type | DIN rail, panel mount, or wall mount |

Honeywell XF823A

Product introduction

The Honeywell XF823A is an advanced building automation controller designed to deliver next-generation performance in managing complex HVAC, lighting, and energy systems across commercial and institutional facilities. As a flagship model in Honeywell’s Excel Web series, this controller builds on the legacy of predecessors like the PXCXF1207882 with enhanced processing power, expanded I/O capacity, and broader connectivity options—making it ideal for smart buildings and large-scale automation projects.

Honeywell XF823A functions as a powerful integration hub, unifying diverse building systems through open protocols to enable data-driven decision-making. Its robust architecture supports both standalone operation and seamless integration into enterprise-level building management systems (BMS), providing facility managers with granular control over energy usage, occupant comfort, and system reliability. Whether deployed in airports, universities, or high-rise commercial towers, Honeywell XF823A sets a new standard for flexibility and efficiency in building automation.

Core advantages and technical highlights

Enhanced processing capabilities: XF823A features a 32-bit ARM Cortex-A53 processor running at 1.2 GHz—50% faster than previous generations—paired with 1 GB RAM and 8 GB flash storage. This processing power enables it to handle advanced algorithms like machine learning-based predictive control, which anticipates HVAC loads based on historical data and weather forecasts. For example, it can pre-cool a conference center before morning meetings or reduce heating in unoccupied classrooms, cutting energy waste without sacrificing comfort.

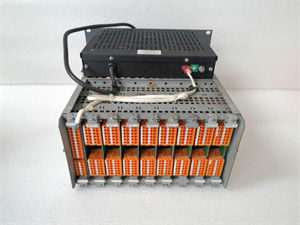

Expanded I/O and scalability: With 16 universal inputs, 12 relay outputs, and 6 analog outputs, XF823A offers 33% more I/O capacity than the PXCXF1207882, supporting larger systems without additional hardware. The universal inputs accept signals from temperature sensors, CO₂ detectors, and flow meters, while outputs control everything from variable air volume (VAV) boxes to lighting panels. For even larger installations, up to 8 expansion modules (like Honeywell’s HIU-800) can be connected, extending I/O capacity to over 100 points.

Multi-protocol integration: XF823A supports a comprehensive range of protocols, including BACnet, Modbus, LonWorks, and optional Wi-Fi—ensuring compatibility with legacy systems and modern IoT devices. This flexibility allows it to connect to smart thermostats, energy meters, and even security systems, creating a unified building ecosystem. For instance, it can adjust HVAC settings when security systems detect a building is empty or coordinate lighting with occupancy data from access control systems.

Extreme environment resilience: Rated to operate from -10°C to 60°C, XF823A outperforms standard controllers in challenging environments like unconditioned mechanical rooms or outdoor kiosks. Its rugged design withstands voltage fluctuations and electromagnetic interference, ensuring reliable operation in industrial facilities or areas with heavy electrical equipment. This durability reduces downtime and maintenance costs in harsh conditions.

Typical application scenarios

Airports rely on XF823A to manage complex HVAC systems across terminals, concourses, and baggage handling areas. The controller monitors temperature and humidity in passenger zones (via 16 inputs) and adjusts air handlers, chillers, and heating coils (via outputs) to maintain comfort levels while minimizing energy use. Its Wi-Fi capability allows remote monitoring of systems in hard-to-reach areas like tarmacs, while integration with flight information systems enables pre-conditioning of gates before incoming flights.

University campuses deploy XF823A to centralize control of diverse buildings, from lecture halls to research labs. In laboratories, the controller maintains precise temperature and pressure differentials using PID algorithms, ensuring compliance with safety standards. It schedules HVAC operation around class times and research activities, reducing energy use in empty buildings by up to 30%. Integration with campus-wide BMS allows facility teams to manage dozens of buildings from a single dashboard.

High-rise commercial buildings utilize XF823A to optimize energy efficiency across floors with varying usage patterns. The controller aggregates data from tenant spaces, common areas, and mechanical rooms, identifying opportunities to reduce peak demand. For example, it can stagger the startup of HVAC equipment across floors to avoid demand spikes or adjust cooling in response to solar gain data from window sensors. Its advanced analytics generate reports that help building owners meet sustainability goals and reduce operational costs.

Honeywell XF823A

Related model recommendations

Honeywell PXCXF1207882: A compact alternative to XF823A with lower I/O capacity, ideal for medium-sized buildings or satellite facilities.

Honeywell HIU-800: I/O expansion module that adds 8 universal inputs to XF823A, enabling larger system configurations in airports or campuses.

Honeywell EBI Enterprise: Building management software that integrates with XF823A to provide enterprise-level monitoring, reporting, and analytics across multiple sites.

Honeywell THERMASTAT-Smart: Wi-Fi-enabled thermostat that communicates with XF823A via BACnet, allowing tenants to adjust settings while maintaining building-wide energy controls.

Honeywell EM5000: Energy management system that pairs with XF823A to track consumption, identify inefficiencies, and automate demand-response actions.

Honeywell LON-800: LonWorks gateway that extends XF823A‘s compatibility with legacy LonWorks devices, simplifying retrofits in older buildings.

Installation, commissioning and maintenance instructions

Installation preparation: Mount XF823A using DIN rail, panel mount, or wall mount options, ensuring the location is free from direct sunlight and excessive vibration. For outdoor or extreme environments, use a NEMA 4 enclosure. Connect to a 24 VAC/DC power supply with 2 A overcurrent protection, using separate circuits for power and signal wiring. Run shielded twisted-pair cable for analog and communication lines, grounding shields at both ends to prevent interference. Label all connections clearly to facilitate troubleshooting.

Commissioning and maintenance: Configure XF823A using Honeywell’s EXCEL Web Commissioning Tool or EBI software, defining input/output mappings, control logic, and communication parameters. Calibrate sensors using certified equipment to ensure accuracy within ±0.3°C for temperature measurements. Test all control sequences, including failover to backup systems, to verify proper operation. Perform quarterly checks to update firmware, clean ventilation ports, and inspect wiring. Annually, verify protocol communication, test relay operation, and recalibrate critical sensors to maintain performance.

Service and guarantee commitment

Honeywell XF823A is backed by a 5-year warranty, with an optional extension to 7 years, covering manufacturing defects and ensuring compliance with BACnet and industry standards. Honeywell’s global technical support team provides 24/7 assistance, with a 2-hour response time for critical issues, including remote diagnostics and on-site support for complex installations.

Customers receive access to specialized training for XF823A programming and integration, ensuring optimal use of its advanced features. Honeywell maintains regional stock of XF823A controllers and replacement parts, enabling next-day delivery for emergency replacements. All repairs use genuine components, with post-repair testing to validate performance and protocol compatibility. This commitment ensures XF823A delivers reliable, efficient operation throughout its lifecycle.